In HP Carbon, as you have your allocated plans, you can select one of them and create next step plans for it. Single next step plan is the stage of polishing of the stone. The stage is related to the specific facet type; it contains the sequence of steps. Each step is related to specific facet and contains information about this facet initial (before polishing) and final (after polishing) states.

Creating Next Step Plans

To create a new next step plan:

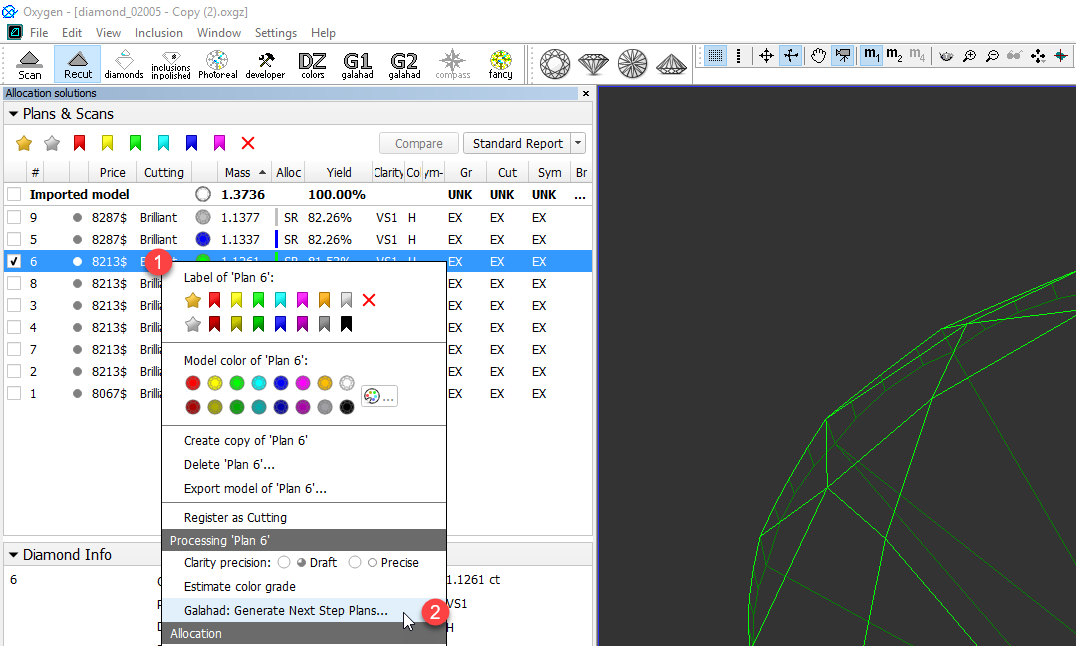

- In the Recut mode, select the target plan.

Switch to the G1 Galahad mode.

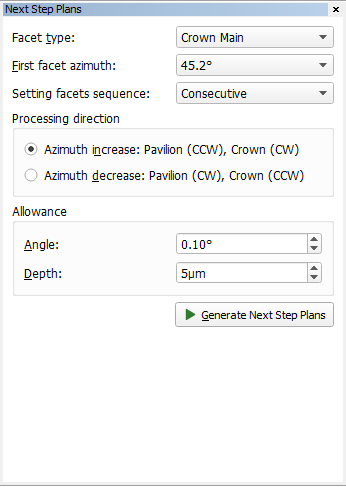

- Click Generate next faceting stage. The Next Step Plans panel is displayed.

- Select Facet type from the list.

- Set next step plan parameters.

- Click Generate Next Step Plans. The stage is created and populated with steps.

Next Step Plan Parameters

| Parameter | Example | Description | |

|---|---|---|---|

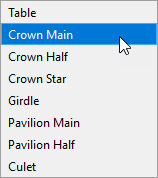

| Facet type | Set of the facet types presented in the list depends on the cutting type and the current Facet Marking. Select the facet type from the list to generate a next step plan (stage) that will include all the steps related to the facets of the selected type. Note The value may also be selected by clicking any facet of the required type in the scene. | ||

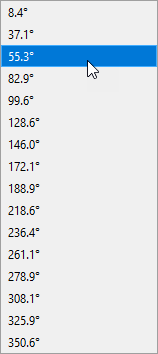

| First facet azimuth | The parameter lists the azimuths of the presented facets of the type, defined by Facet type. The selected value defines the facet which will be polished on the first step. The value may be selected from the list or by clicking the required facet in the scene. | ||

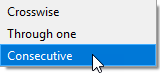

| Setting facet sequence | Together with Processing direction, defines in which order the facets will be polished starting from the one defined by First facet azimuth:

| ||

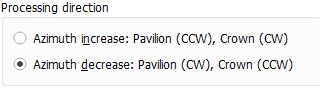

| Processing direction | Together with Setting facet sequence, defines in which order the facets will be polished starting from the one defined by First facet azimuth:

| ||

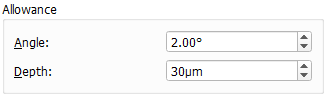

| Allowance | Defines whether facets should be polished up to the brilliant (0.00° and 0.00µm) or with some allowance. You can set allowance for the depth in µm or for the angle in ° or combine these two allowances. Setting allowance for the next step plan allows polishing the same facet types within several different next step plans (stages). For example, you can polish Crown Main facets with the allowance of 10µm for the depth on one stage, and then finalize polishing these facets in a later stage up to the end (0.00µm allowance). Notes

|

Add Comment