Here you can find information about HP Carbon version 1.0.2. It describes differences between HP Carbon and its predecessor, the HP Oxygen version 5.4.7.

Main Features

AnyCut Workflow

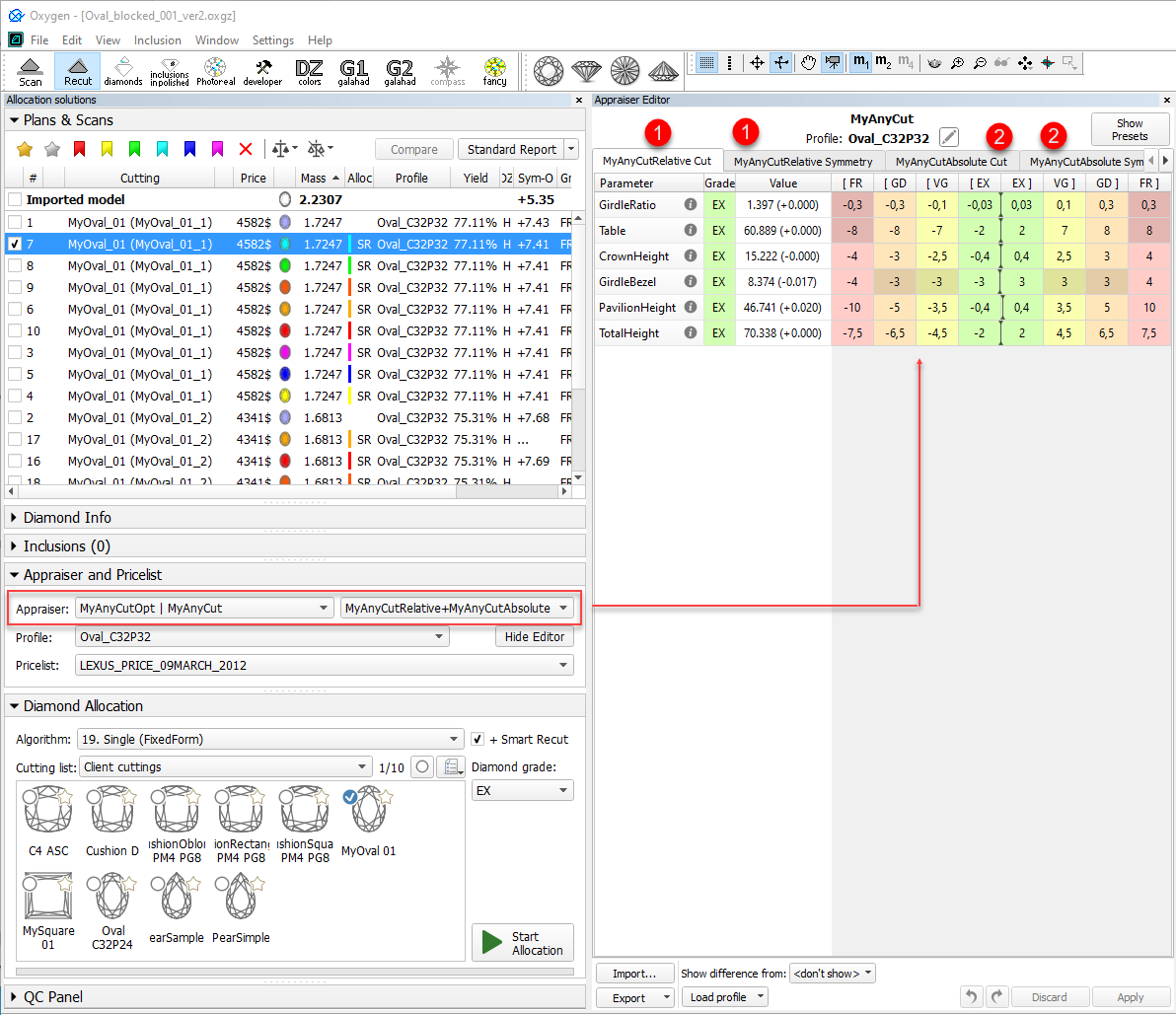

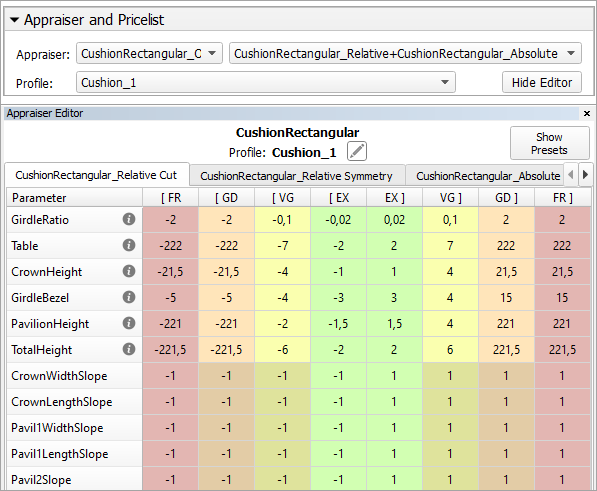

AnyCut Composite Appraiser

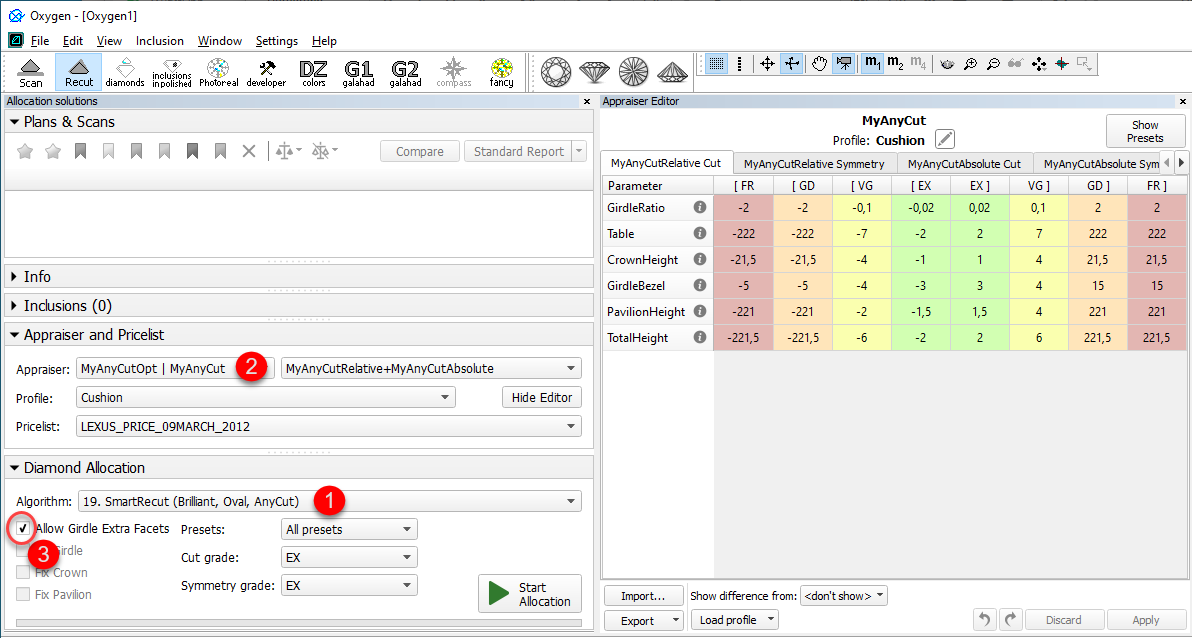

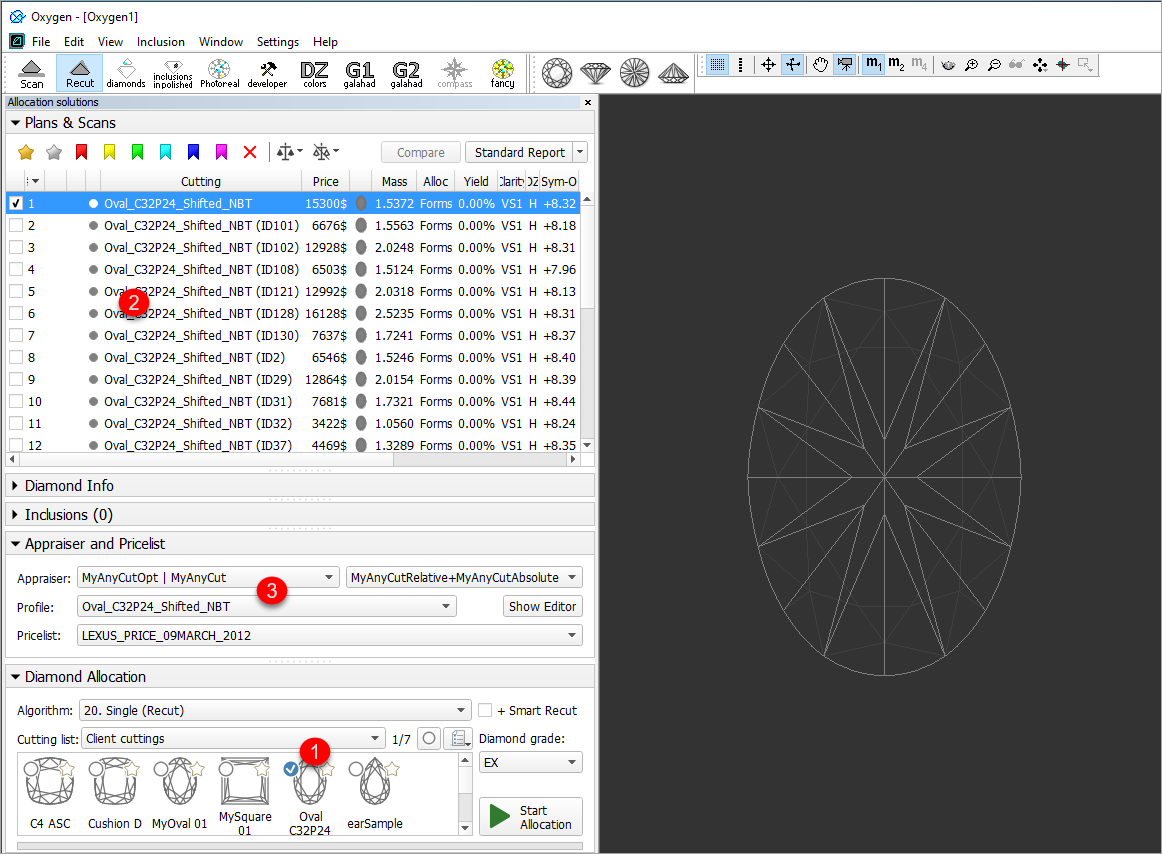

The AnyCut relative appraiser ("MyAnyCutOpt | MyAnyCutRelatve") has been transformed into the "MyAnyCutOpt | MyAnyCut" Composite appraiser. The new appraiser combines relative and absolute appraisal of the created solutions so that if you are aiming to get some grade, both absolute and relative parts should have at least this grade, which means the algorithms will be searching within the intersection of the relative and absolute values.

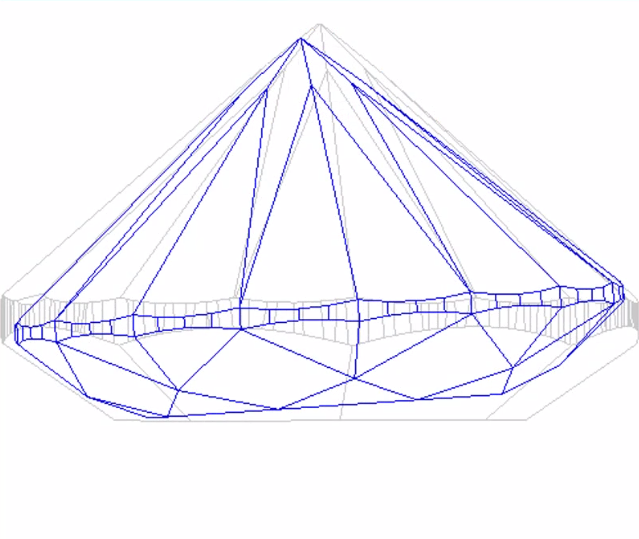

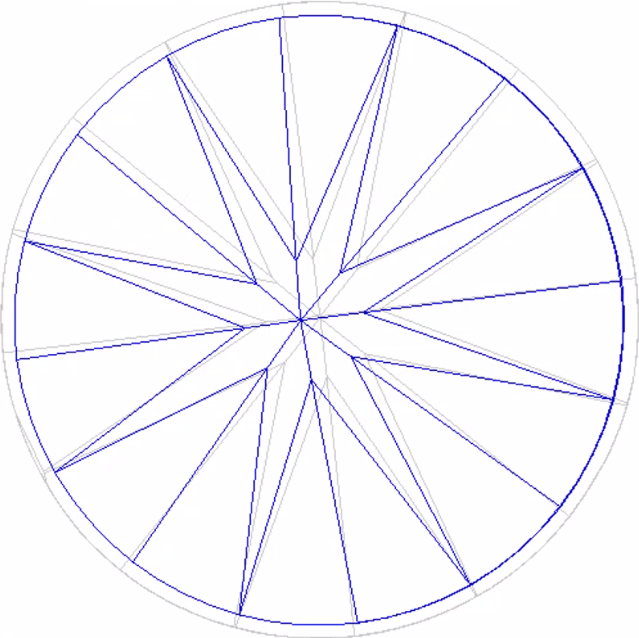

On the figure: 1. Relative part, 2. Absolute part.

Three modes are available:

- Relative + Absolute

- Relative only

- Absolute only

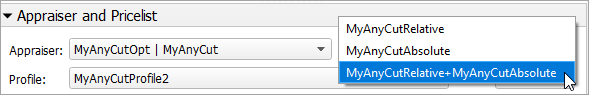

To switch between modes, use the control to the right of the composite appraiser name:

Notes

- Each profile of the composite appraiser defines both relative and absolute intervals. Profiles are editable (for details, see "Configuring Profiles" in Algorithms, Appraisers and Profiles.

- Relative intervals depend on the selected cutting. See In-house cut workflow.

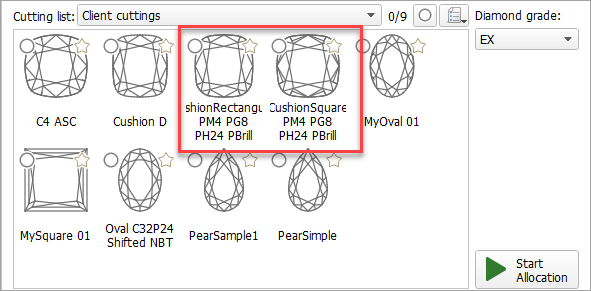

Appraisers for Cushion

For In-house cut workflow, two new appraisers are added - both for working with the Cushion cutting:

| When to Use | Appraiser | Cutting for Relative Part** |

|---|---|---|

| For square* Cushion | "CushionSquare_Opt | CushionSquare" | "CushionSquare_PM4_PG8_PH24_PBrill_C32" |

| For rectangular Cushion | "CushionRectangular_Opt | CushionRectangular" | " CushionRectangular_PM4_PG8_PH24_PBrill_C32" |

* Rt (Girdle Ratio) = 1.05 distinguishes "square" (up to and including 1.05) and rectangular (1.06 and more) where Rt is rounded till the second decimal place.

** For now, the appraisers work only with these cuttings; cuttings are stored under Client Cuttings .

Both appraisers are composite - they intersect absolute parameter limits with the limitations relative to the cutting listed in the table above. Three modes are available:

- Relative + Absolute (default)

- Relative only

- Absolute only

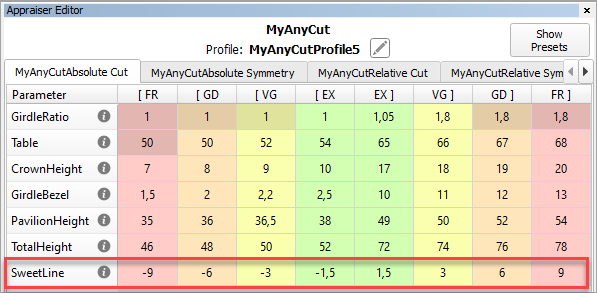

SweetLine for AnyCut

By analogy with the SweetLine parameter for Brilliant and Oval cuts, the system now allows working with SweetLine for AnyCut. Thus the SweetLine parameter is now presented additionally in the following appraisers:

- MyAnyCutOpt | MyAnyCut

- CushionSquare_Opt | CushionSquare

- CushionRectangular_Opt | CushionRectangular

The parameter meaning and usage are the same as for the Brilliant cut.

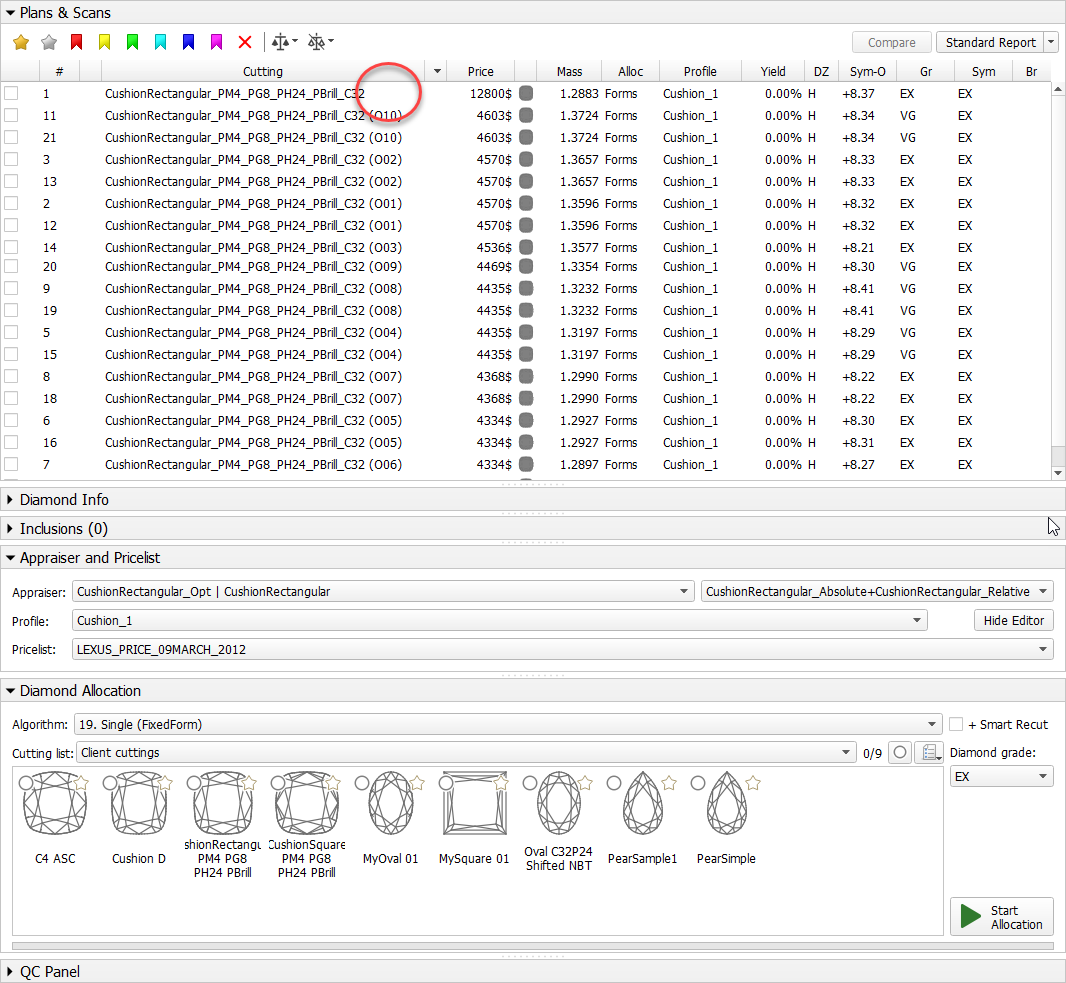

Specifying Unique SweetLine Slope for Client Cuttings

Now for each of the Client Cuttings, you can specify a unique SweetLine axis slope using its allocation forms (for information about user cuttings and allocation forms, see In-house cut registration ). There are three ways of how SweetLine axis slope is specified for the cutting:

The user did not specify any specific forms: the SweetLine axis is built using the base allocation form of the cutting - the system uses this form and draws a line through it in accordance with the built-in system logic for finding optimal optical performance.

- The user specified only one form: the SweetLine axis is built using this form - the system uses this form and draws a line through it in accordance with the built-in system logic for finding optimal optical performance.

- The user specified two forms: the SweetLine axis is built using these forms - the system draws a line through them.

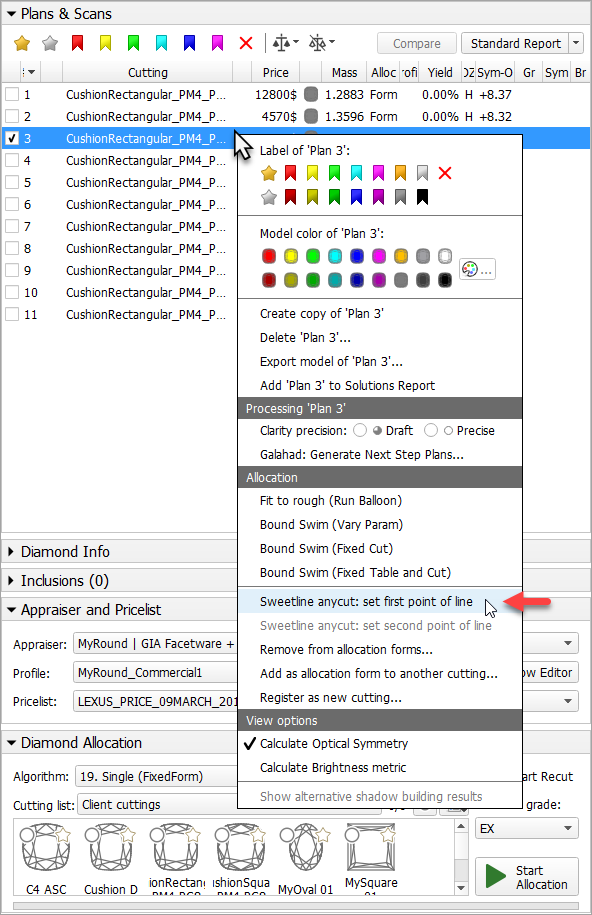

To specify forms for SweetLine for your cutting:

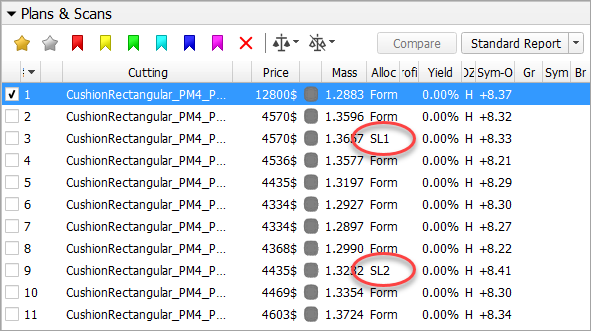

- Show allocation forms of your cutting as described here.

- Right-click the appropriate allocation form and select Sweetline anycut: set first point of line.

- If necessary, select another allocation form and select Sweetline anycut: set other point of line .

The selected points are marked in the Allocation column as "SL1" and "SL2".

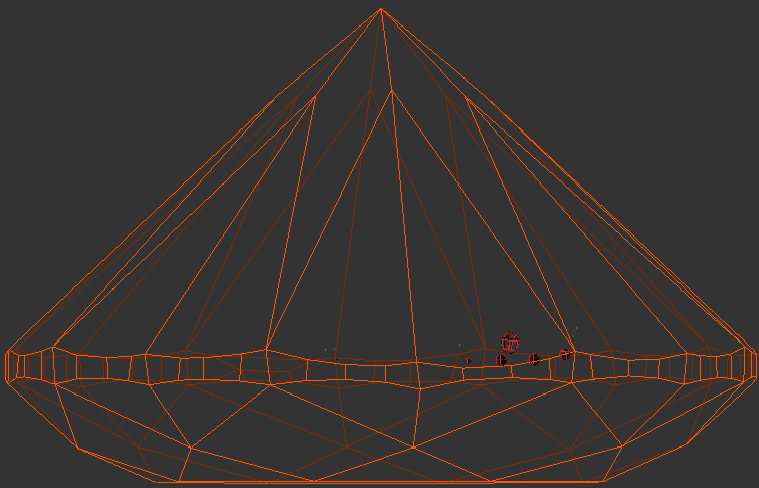

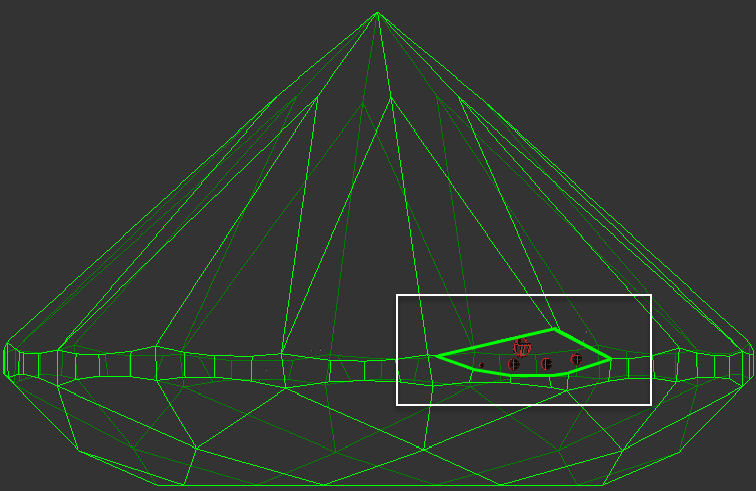

Smart Recut AnyCut - Using Girdle Extra Facets

Now when using the "19. SmartRecut (Brilliant, Oval, AnyCut)" algorithm with the "MyAnyCutOpt | MyAnyCut" composite appraiser, you can enable the Allow Girdle Extra Facets option. The option is used to enlarge the mass of the solutions by instructing the system to produce the extra facets if possible.

For now, you can regulate the number of extra facets and their height via presets.

Note

You can also use the Allow Girdle Extra Facets option with the "19. SmartRecut (Brilliant, Oval, AnyCut)" algorithm and the two new appraisers for Cushion:

- "CushionSquare_Opt | CushionSquare "

- "CushionOblong_Opt | CushionOblong"

Other Changes

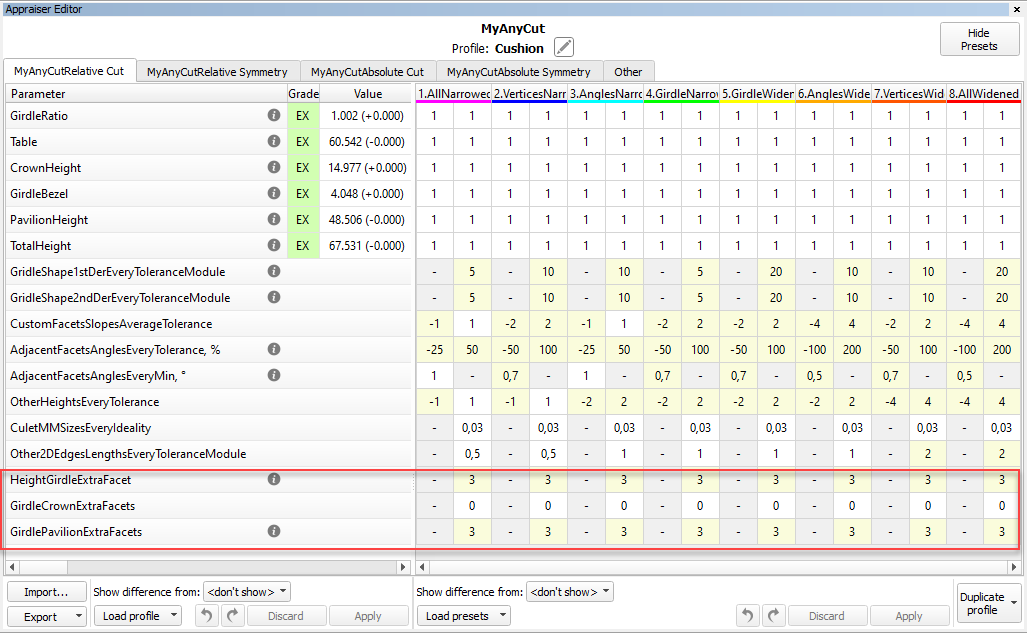

New Parameters for AnyCut

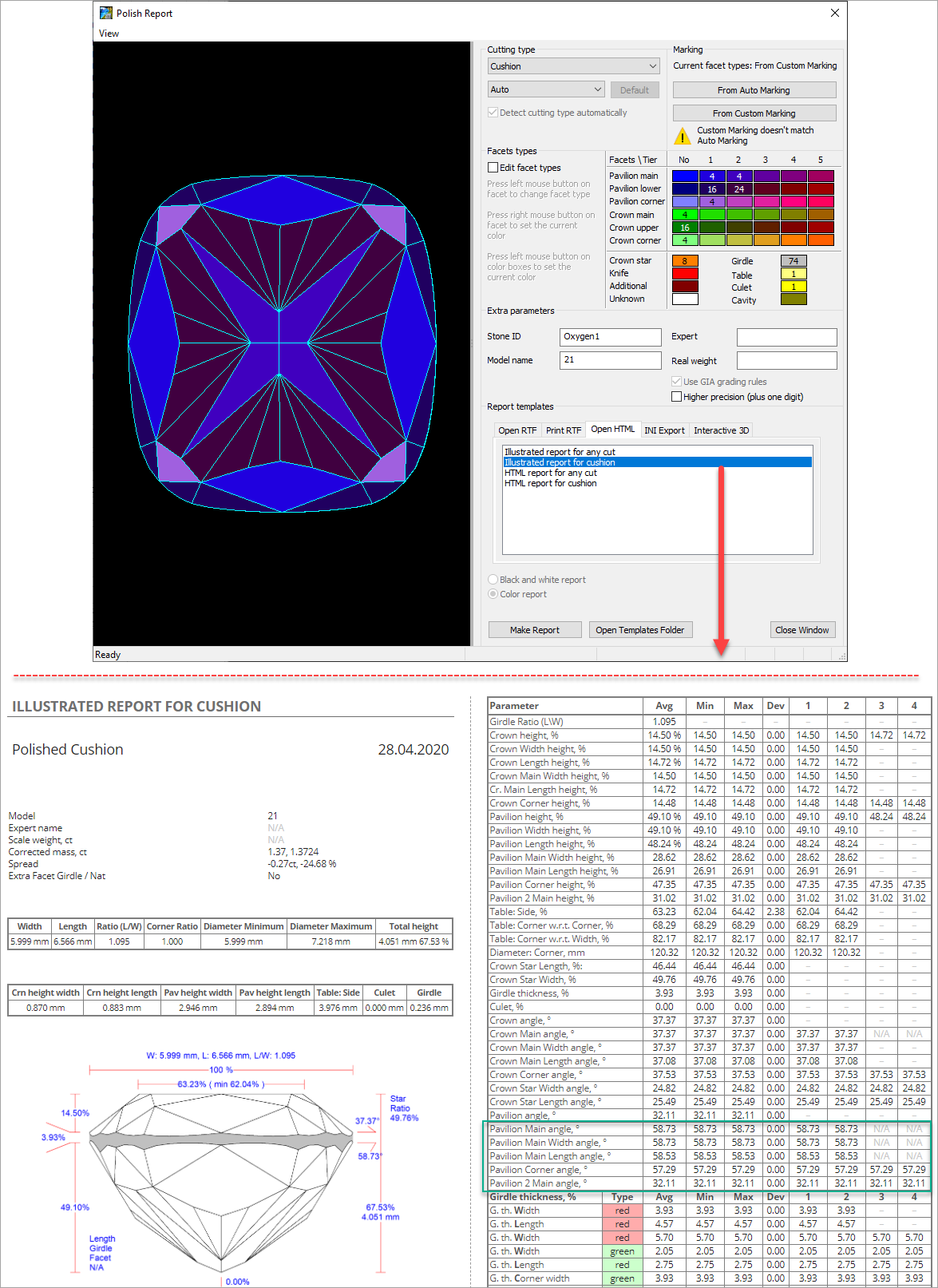

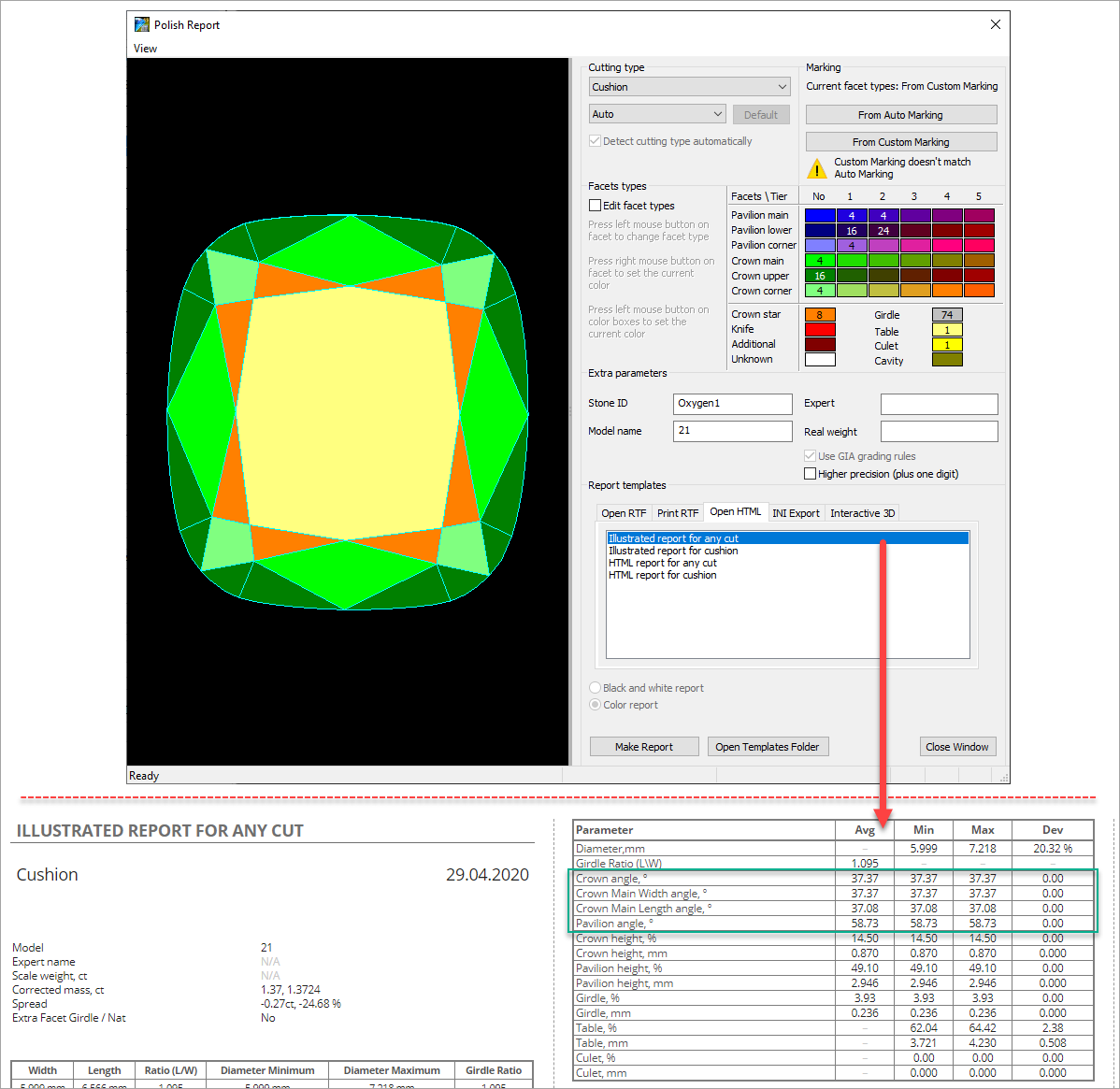

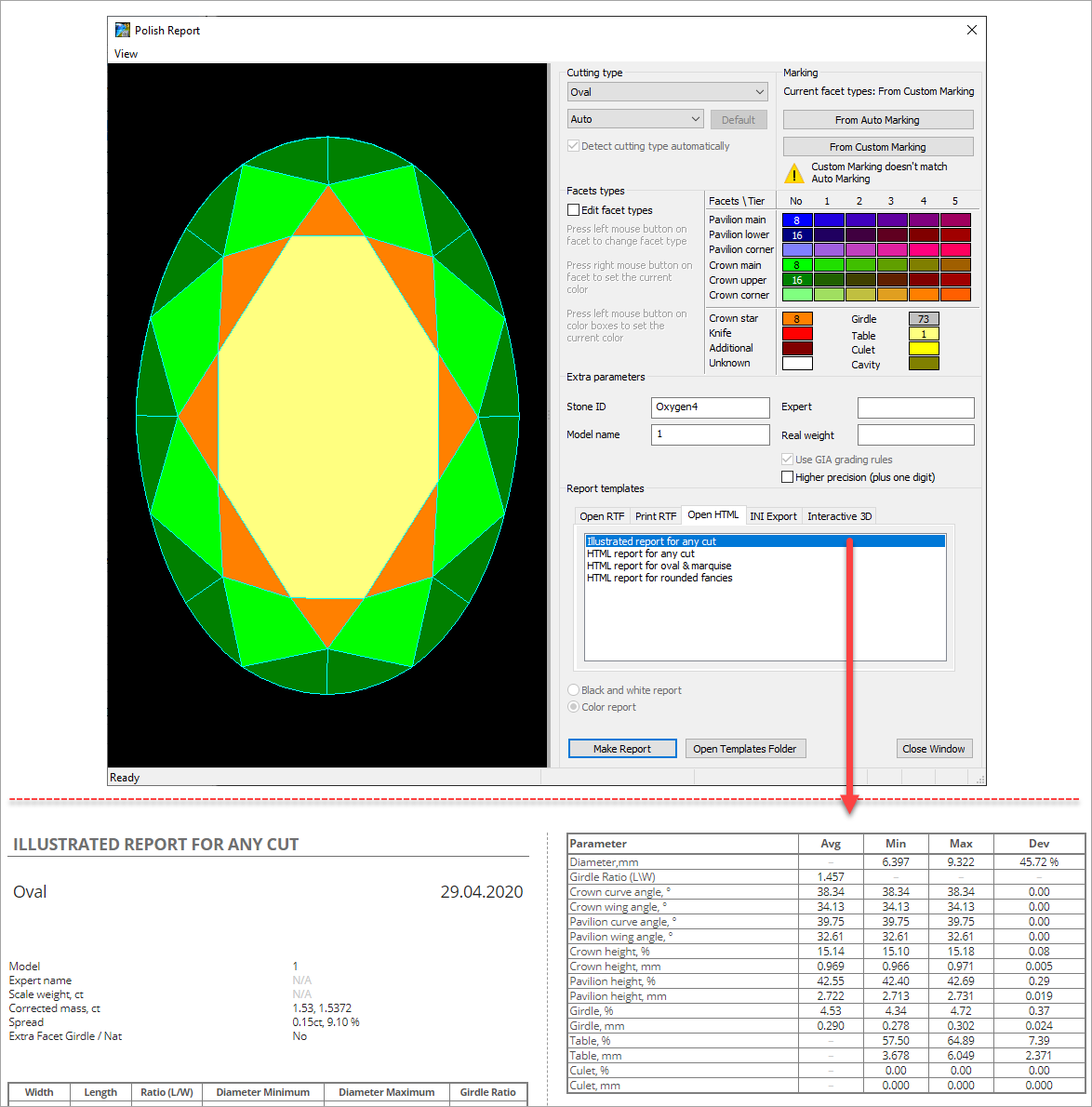

The set of parameters for AnyCut has been extended. This affected the Standard Report for AnyCut and HTML illustrated Polish Report for AnyCut.

The behavior of these reports is now adaptive and dynamic which means:

- The set of displayed parameters depends on the current model Facet Marking - "empty parameters" (making no sense for the current model) will not be displayed.

- For the Cushion - the set of displayed parameters is different for Square and Rectangular cushions

Some examples:

More examples:

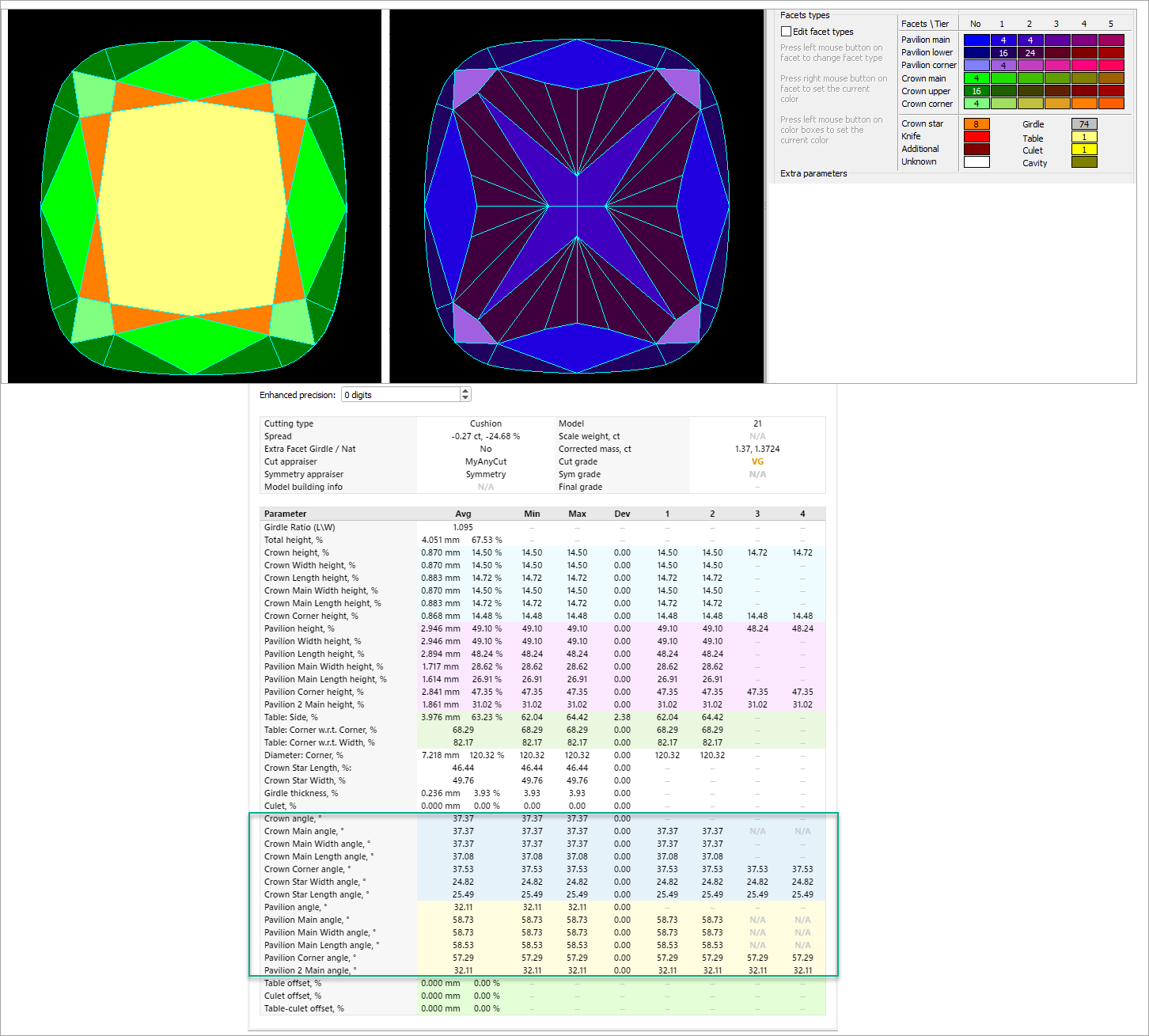

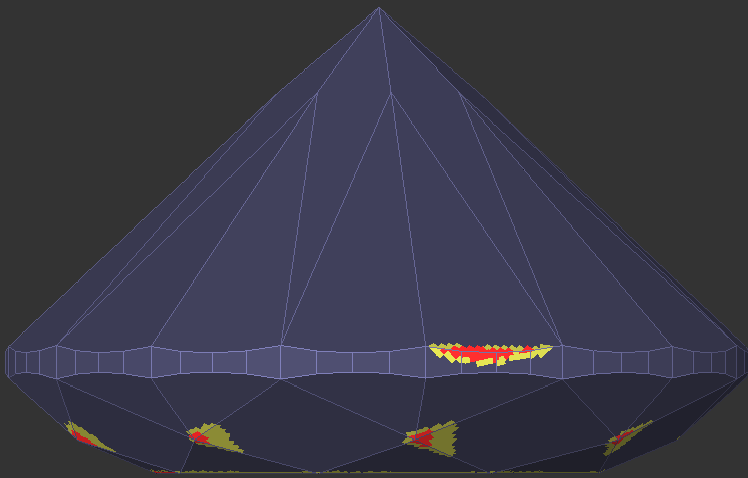

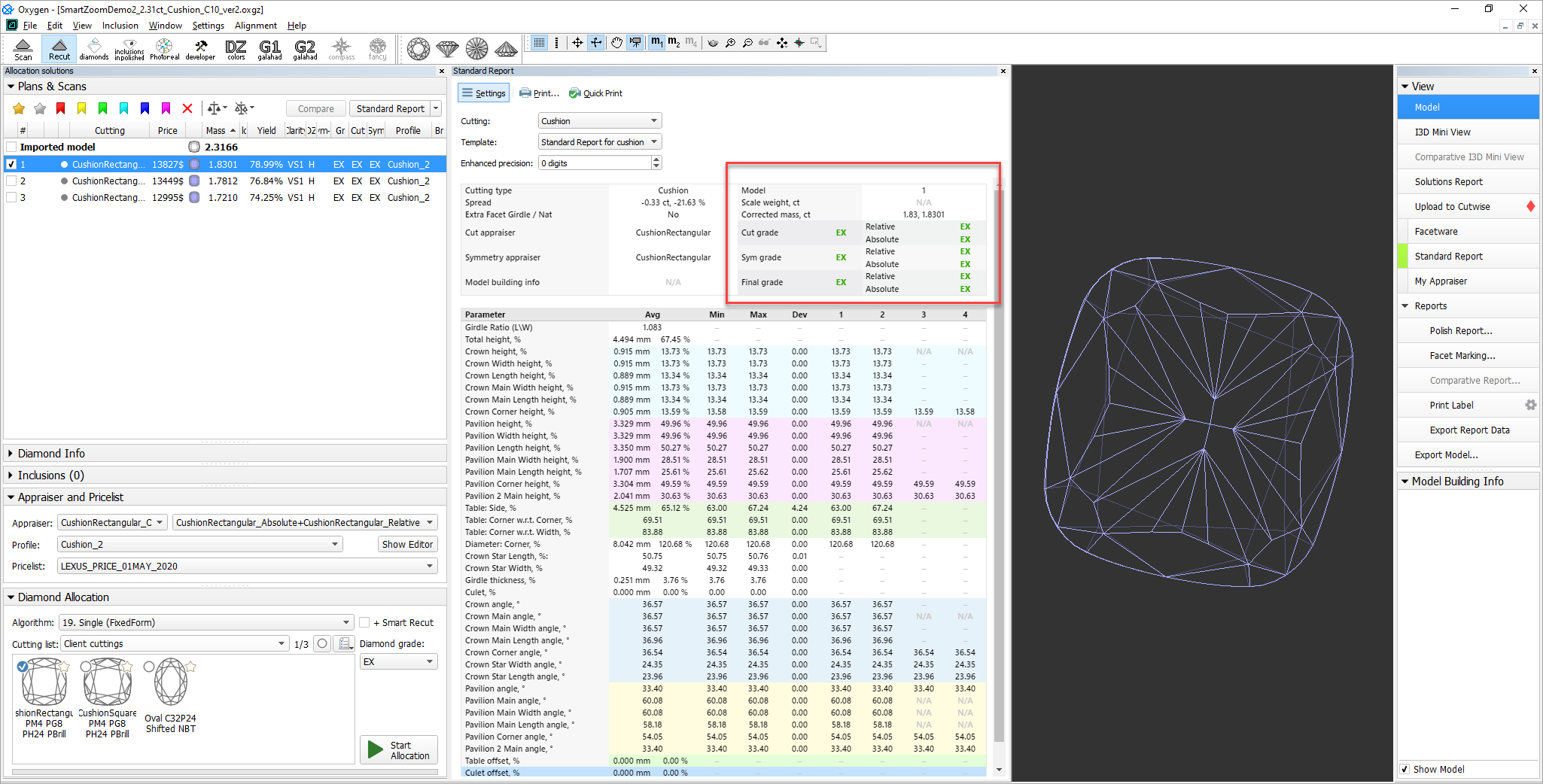

Some of the new parameters are also available for controlling via appraisers, for example, with the new appraisers for a cushion. Here is the example for the CushionRectangular Appraiser:

AnyCut Demo Cutting

For demonstration purposes, the "Oval_C32P24_Shifted_NBT" cutting is added to Client cuttings, along with the corresponding profile under the AnyCut composite appraiser ("MyAnyCutOpt | MyAnyCut"). The cutting contains a number of allocation forms. The cutting and the appraiser may be used within In-house cut workflow for testing purposes. Using the "Oval_C32P24_Shifted_NBT" is optional.

On figure: 1 - demo oval cutting; 2 - allocation forms within cutting; 3 - AnyCut composite appraiser with the corresponding profile.

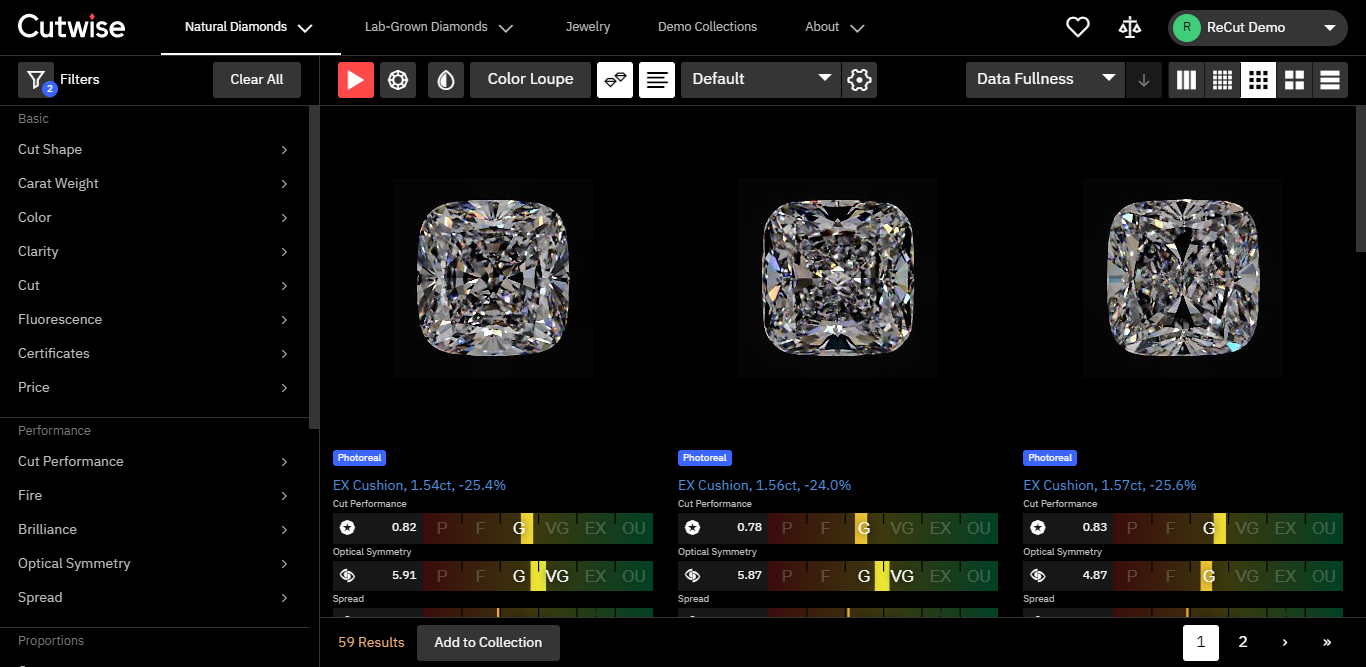

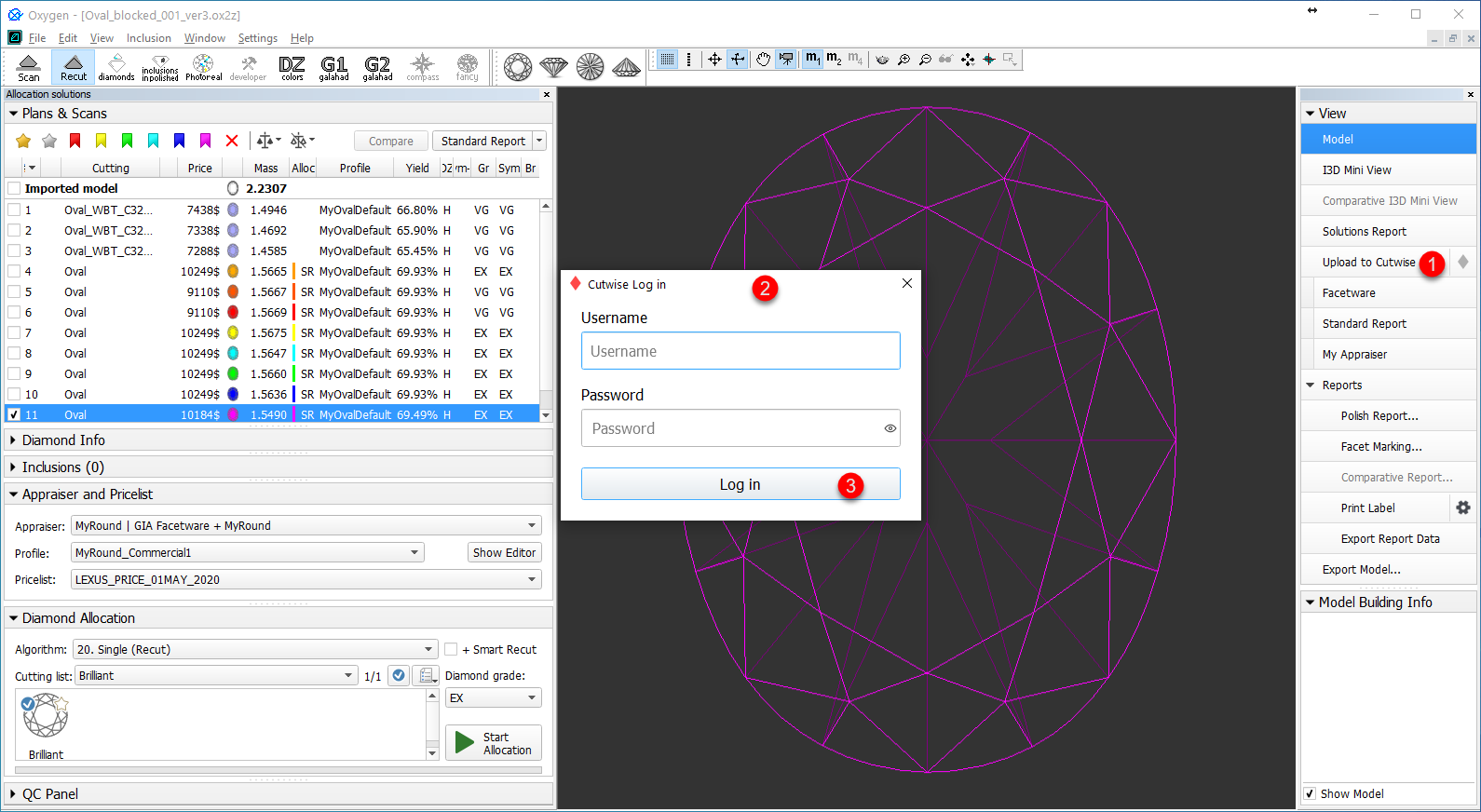

Integration with Cutwise

General Usage

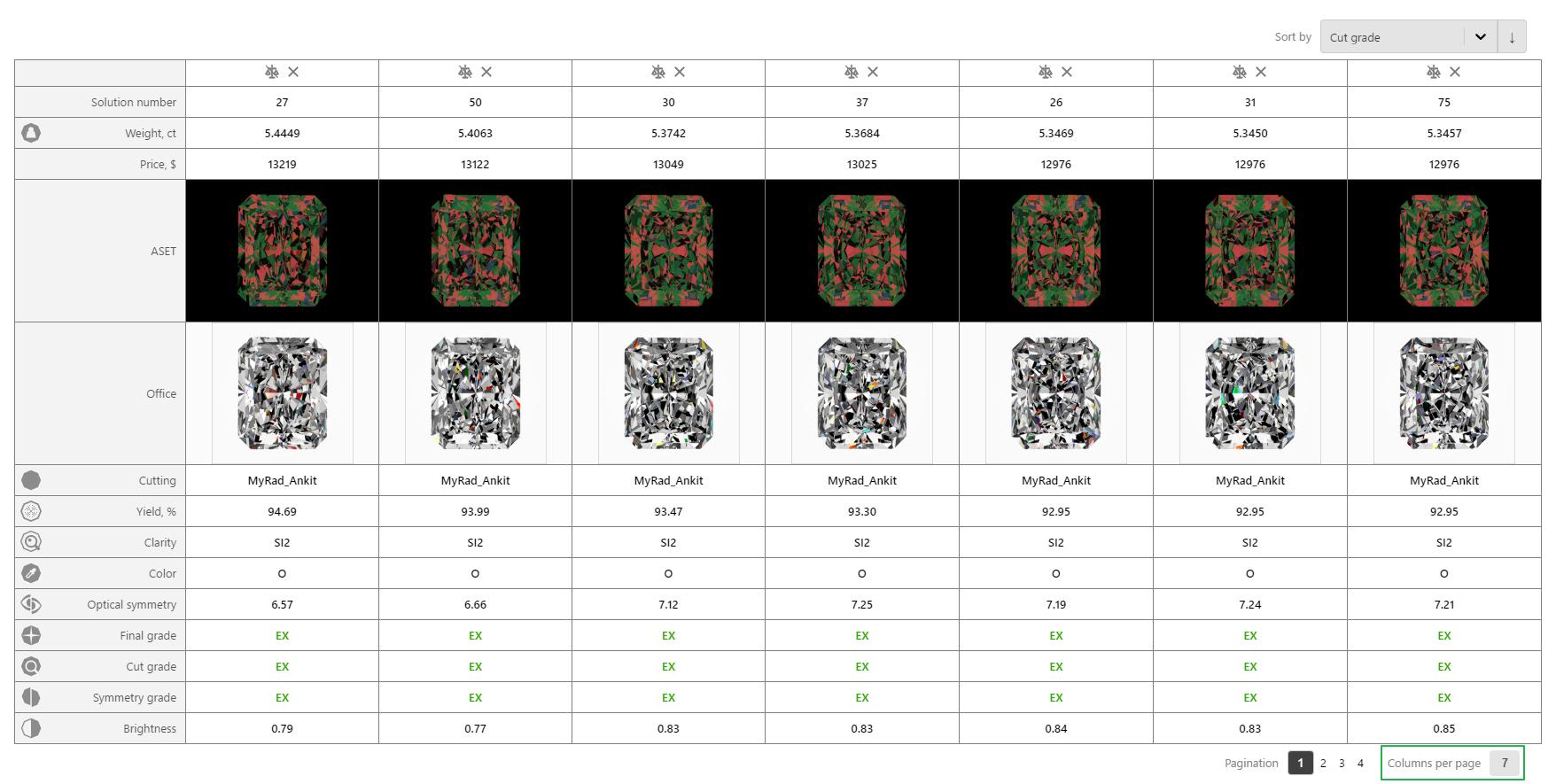

After obtaining the set of SmartRecut solutions, it is an essential task to compare them to select one or several best. HPO provides tools for this comparison. But these tools separately or combined not always provide the best experience for solutions comparison task. The OctoNus Cutwise online service offers an extended set of tools for presenting and comparison of brilliants and their models. Now HPO supports integration with Cutwise: the models from HPO may be sent in one click to the Cutwise where they can be further visualized and analyzed with the rich set of tools.

One of the main advantages of Cutwise is a new generation of virtual films. They are renderings of future stones, indistinguishable from the real DiBox2 films for both Round and Fancy cuttings. This allows effective visual comparison of future solutions. Moreover, the additional visual metrics are built on the basis of the films and comparison by these metrics become available. The Cutwise uses special film generating systems that have a naturally high consumption of the hardware resources and time. As the Cutwise cloud keeps film calculations server-side, it frees up resources of the HPO machine as well as the time of an operator.

The Cutwise has a modern web interface. It includes advanced, effective tools for:

Stone visual and parametric representation.

Sophisticated filtering.

Convenient sorting.

Saving you selections as separate sharable collections.

Also, being accessible via Internet 24/7, Cutwise is a great place to share created stone collections. You can share them with the colleagues to demonstrate stones and delegate or share decision making responsibilities. You can also present full stone information to future customers.

Detailed information and the example you can find in the video:

Video summary: After obtaining the set of SmartRecut solutions, it is an essential task to compare them. OctoNus Cutwise online service offers an extended set of tools for presenting and comparison. HP Carbon supports integration with Cutwise: models from HP Carboon may be sent to Cutwise where they can be further visualized and analyzed. Cutwise generates virtual films presenting stones and calculates metrics based on films. Cutwise presents models images for Fire, Office, and ASET. HP Carbon parameters are also transferred to Cutwise. Cutwise cloud keeps all operations server-side. Cutwise is a comfortable tool for comparison and selecting the best. Selected stones can be saved in collections. You can share created collections 24/7 for discussion and sales. Video keywords: ASET, cloud, Cutwise, filtering, fire, integration, metrics, model comparison, office, parameters, share, sorting, upload DocumentationVideo | Upload to Cutwise - Solutions Comparison Published: 2020, March 17 Last Updated: 2020, June 5 v.1.3 Published in: Release Notes Playlists Integration with Cutwise | YouTube: HP Carbon, HP Carbon - Cutwise Integration, Cutwise Also As Separate Page | On YouTube | Specification

Sharing Polished Diamond Data

You can now quickly share via the Internet your stone information using an integration of HP Carbon, DiBox 2.0, and Cutwise OctoNus products.

Some details and example are presented in the video:

Video summary: You can quickly share via the Internet your stone information using an integration of HP Carbon, DiBox 2.0, and Cutwise OctoNus products Upload information collected with HP Carbon and DiBox 2.0 to Cutwise online service Send data in either order - Cutwise will consolidate them to form the full-data representation of your stone online In Cutwise, your product will contain photos and videos from DiBox and information from HP Carbon: main stone parameters, advanced reports with images, I3D report, HTML report, DMC file In Cutwise, share with whom you need to make your product information available around the globe 24/7 Video keywords: Cutwise, DiBox, DMC, HP Carbon, HTML, I3D, images, integration, online, parameters, reports, share, upload, videosVideo | Upload to Cutwise - Polished Diamond Data Published: 2020, June 5 Last Updated: 2020, June 5 v.1.2 Published in: Release Notes Documentation Integration with Cutwise Playlists Integration with Cutwise | YouTube: HP Carbon, HP Carbon - Cutwise Integration, Cutwise Also As Separate Page | On YouTube | Specification

Working with DM-Xray (DMX) Files

Opening DMX Files

The system now supports importing DMX files created in DM-Xray. For more information about DMX files, see "Protected DMX export" in DM-Xray 1.0.0.1 "What's New".

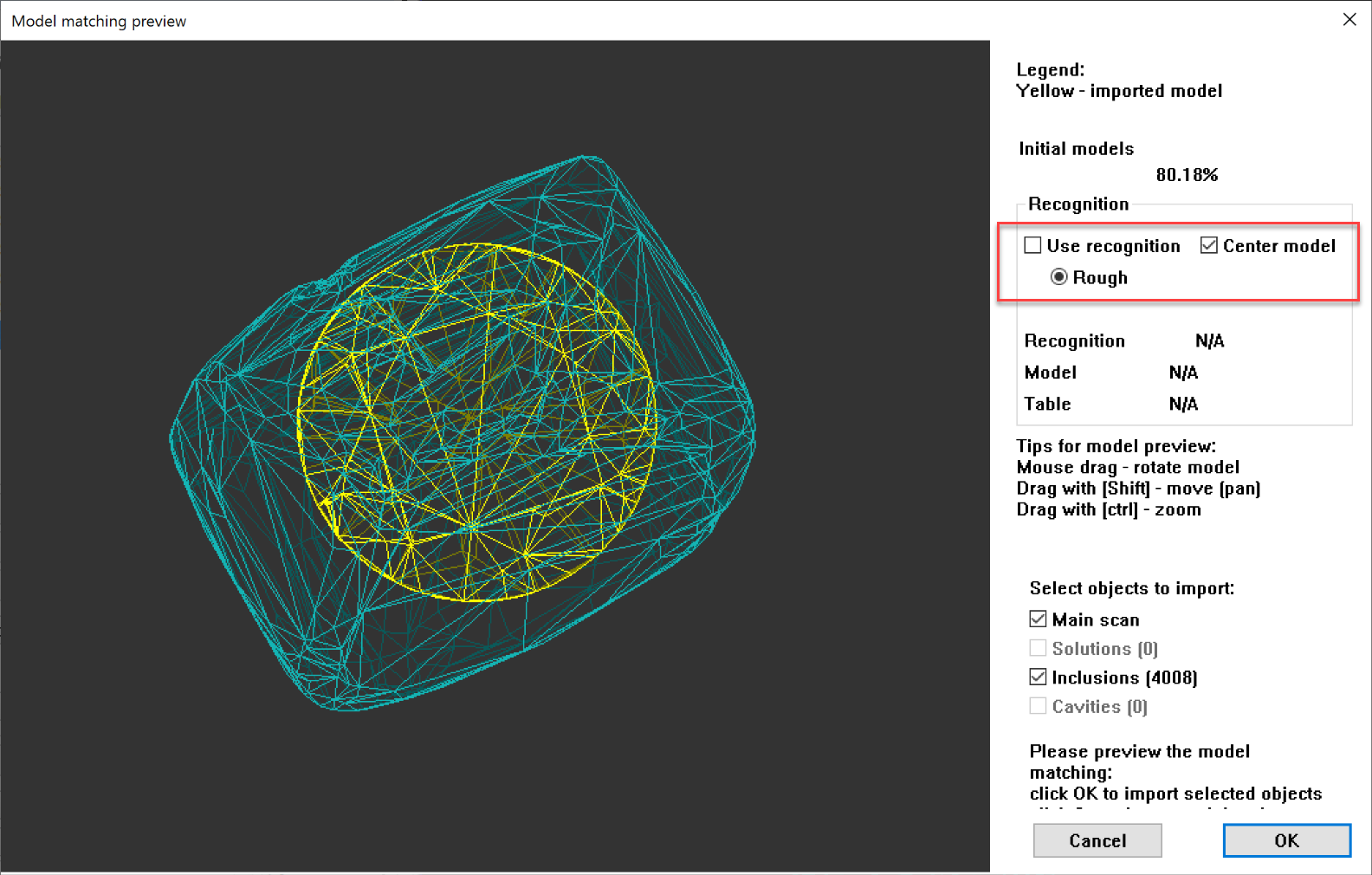

Importing DMX Models - Using Recognition and Centering Model

On importing DMX models (via File > Import), now the Model matching preview dialog is displayed:

Here you can do one of the following:

- Use recognition or

- If you do not use this option you can Center model if necessary

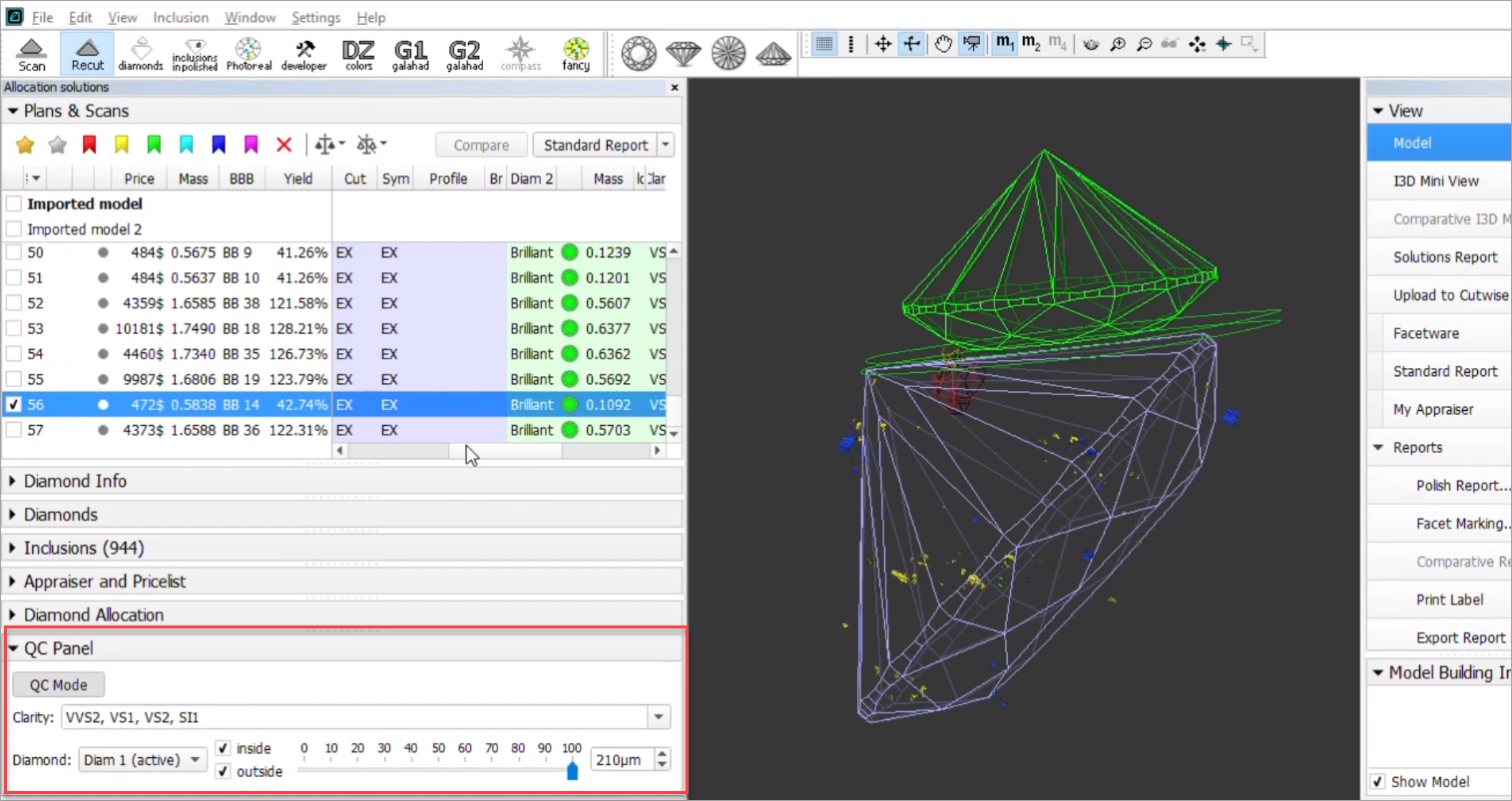

QC Panel - Inclusions Visualization

Now you can filter inclusions visualization in Scene. This can be done via the new QC Panel (Quality Control Panel), available in the Recut mode, on the left panel.

Activate the QC Mode button to start using specified filters. De-activate it - all solution inclusions will be displayed without filtering.

The QC Panel applies filters to the model inclusions, such as:

- Clarity select one or several clarity values from the list - only inclusions with the specified clarities will be displayed

- Diamond for multiple diamond solutions you can select only inclusions for the selected diamond will be displayed

- Inside/Outside check if to display inclusions inside, outside the diamond or both

- Depth of the area where to display the inclusions (works together with Inside/Outside ) - use the slider or type in the value in µm

Filters utilize the AND logic, for example, if "Diamond 1", VS1 clarity, "inside" and 90 µm are selected, then only VS1 inclusions within 90 µm area inside Diamond 1 will be displayed.

Notes

- For now, the diamond filter cannot work with nonconvex models.

- Rarely, some filter combinations may cause the filter to fail, the system shows notification - try other parameters if so.

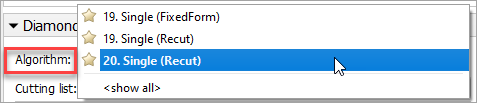

New Algorithm - "20. Single (Recut)"

The new "20. Single (Recut)" algorithm is added to the system. The new algorithm is the improvement of the "19. Single (Recut)". The "20. Single (Recut)" is intended, like its predecessor, to be used for the solution allocation within In-house cut workflow (see "Allocation" section for details). The algorithm is expected to produce better solutions than the "19. Single (Recut)" - during the testing period both algorithms will be presented in the system. On success testing, the "20. Single (Recut)" will replace the "19. Single (Recut)" and in prospect also the "13. Single (Rough)" algorithm.

Other Features

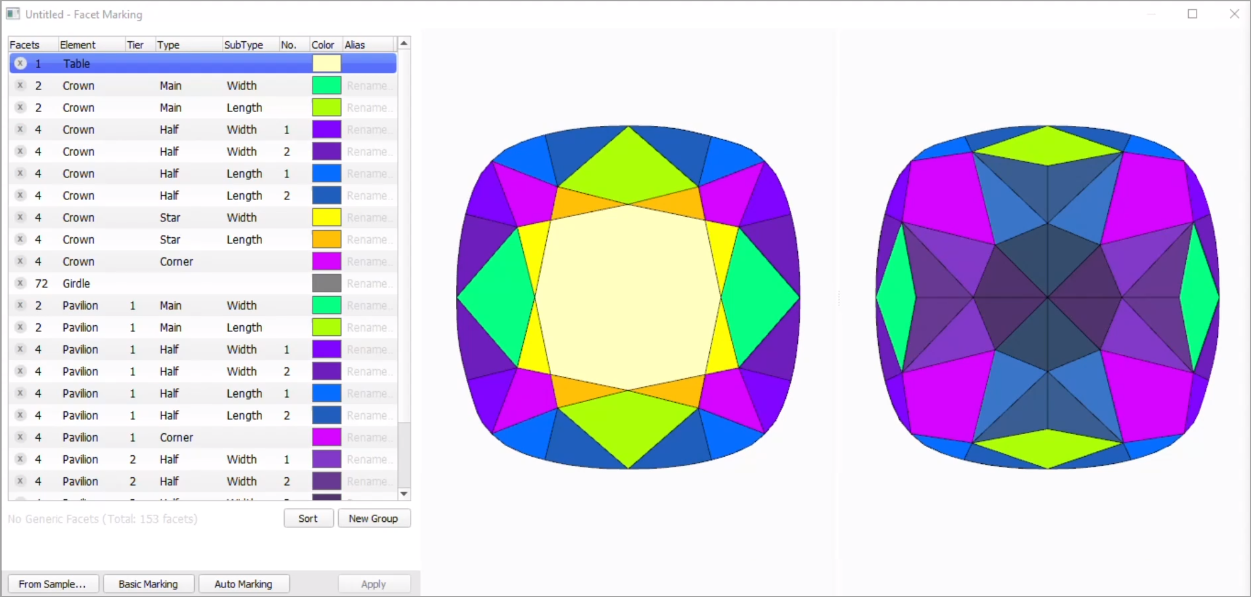

Facet Marking

Improved Integrity

For more comfortable manual facet marking, now Tier, Type and SubType depend on Element and Type - only values making sense for the selected Element/Type are available. Previously you could select any Type-SubType for any element and Tier where it was inapplicable which led to mistakes.

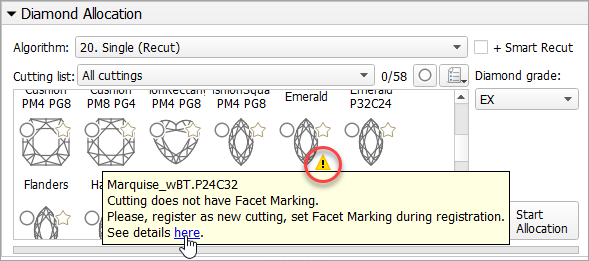

Notification for Cuttings without Facet Marking

Now in the Recut mode, in the Cutting list section, if your cutting does not have a facet marking, it is marked with the icon. On mouseover, the following message is displayed: "Cutting does not have Facet Marking. Please, register as new cutting, set Facet Marking during registration."

See detailed description on how to resolve the problem in Troubleshooting: Cutting Does Not Have Facet Marking

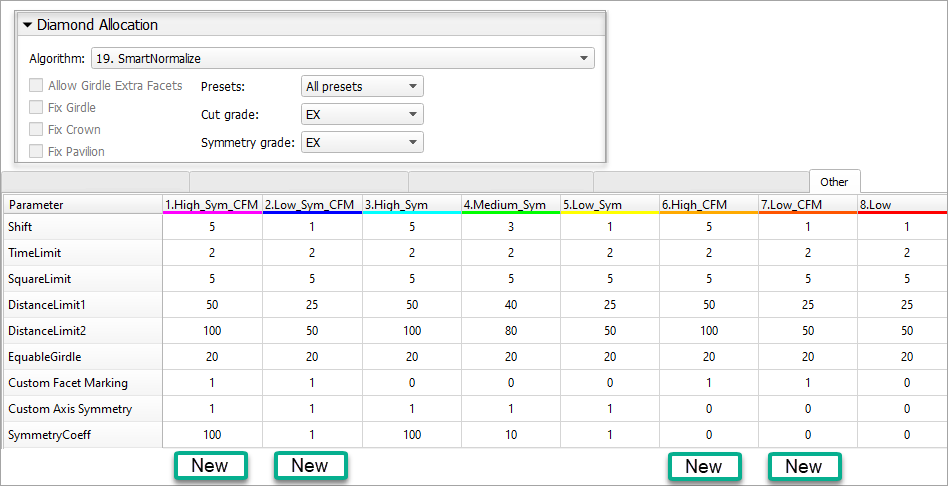

Smart Normalize - New Presets with Custom Facet Marking

The “19. SmartNormalize” algorithm has its own set of presets independent of appraisers. Now, this set is extended and includes new presets. New presets take into consideration additionally or only a custom facet marking (CFM) of the model while the old one worked only with the symmetry axis. Where CFM is taken into consideration, the facets from the same CFM group will obtain the same Slope Angle.

On the picture:

|

So this extends the abilities of the Smart Normalize algorithm considering producing the optimal solutions. The following is important:

- For the cuttings with 1, 2, 3 or 5 symmetry axis, the old "Sym" presets work fine.

- For the cuttings with 7 or 11 symmetry axis or in case of problems with the automatic detection of symmetry axis, "only CFM" presets are good.

- For the cuttings with 4, 6, 8, 9, 10 symmetry axis the best results will be provided by the "Sym"+"CFM" presets.

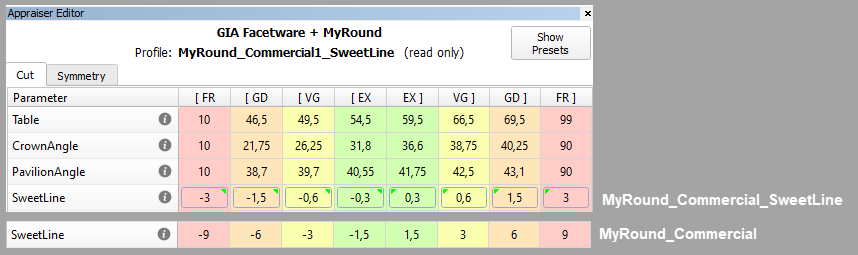

MyRound Appraiser

New Commercial SweetLine Profile

For the "MyRound | GIA Facetware + MyRound" appraiser, the new MyRound_Commercial_SweetLine profile has been added.

| MyRound_Commercial | MyRound_Commercial_SweetLine |

|---|---|

| Parameter ranges statistically match the brilliants produced by the large manufacturer. | Allows getting a result similar to MyRound_Commercial, but with better optical performance due to narrowed limits for the SweetLine parameter. |

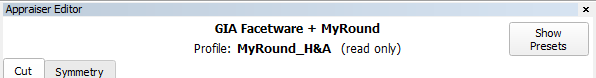

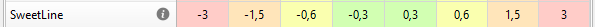

H&A Profile - New Boundaries for SweetLine Parameter

To obtain more solutions with an excellent Hearts & Arrows pattern, in the "MyRound | GIA Facetware + MyRound" appraiser, for the "MyRound_H&A" profile, the limits for the SweetLine parameter have been changed.

| Now | |

|---|---|

| Was |

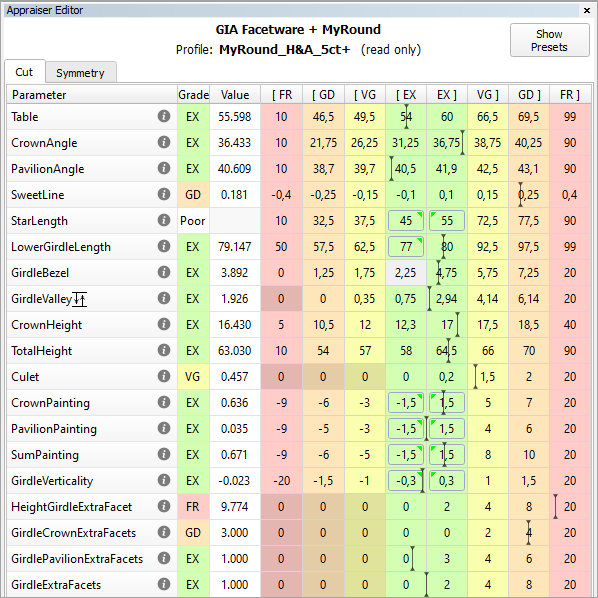

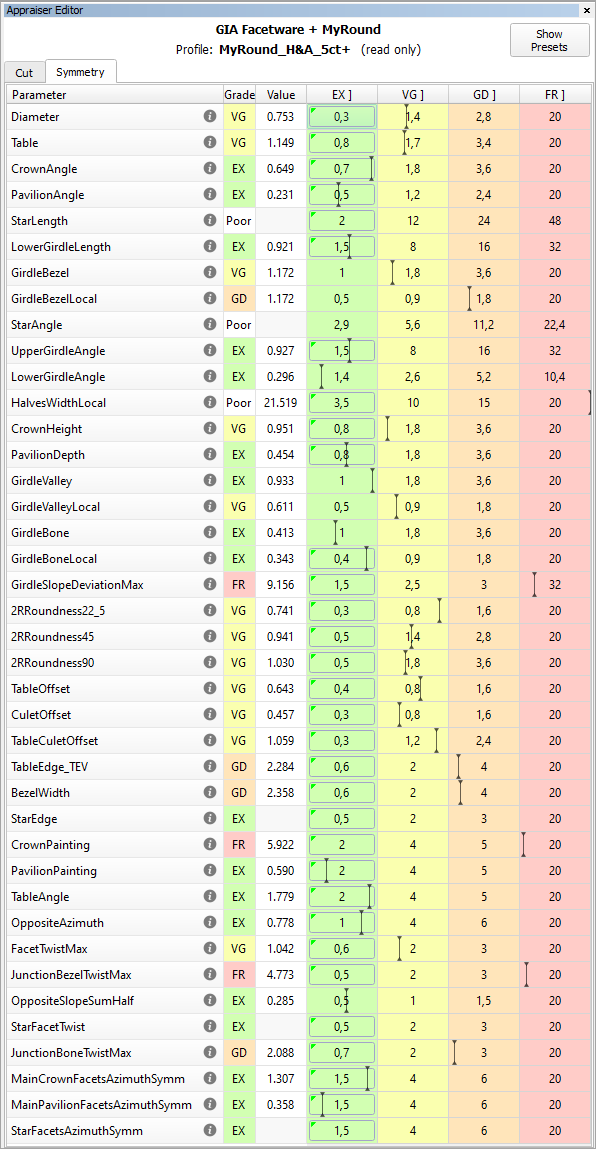

New "MyRound_H&A 5ct+" Profile

To create better solutions for the big (5ct+) stones, under the "GIA Facetware + MyRound" appraiser, the new "MyRound_H&A 5ct+" read-only profile has been added.

Its main differences from the standard "MyRound_H&A" profile are:

- StarLength EX set to 45-55 (istead of 42.5-57.5)

PavilionPainting EX set to 1.5 degrees (from 2.5)

Symmetry parameters have been narrowed

All these changes aim to produce highly symmetrical solutions with correct proportions for the big stones.

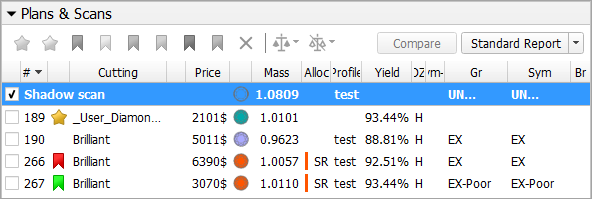

Smart Recut

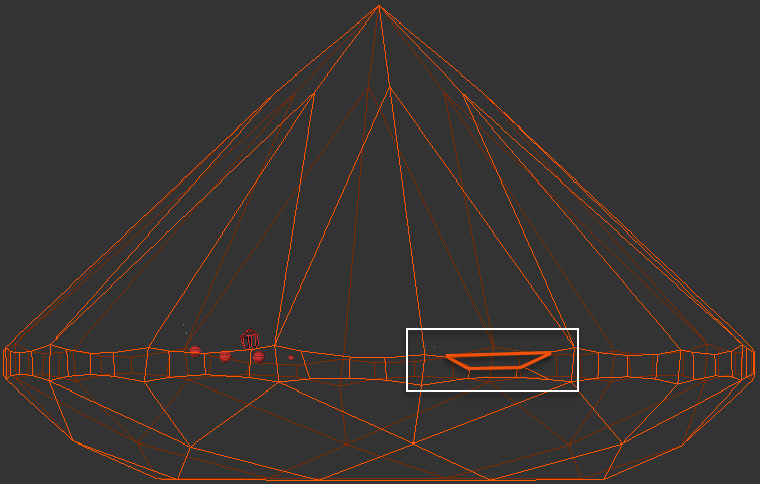

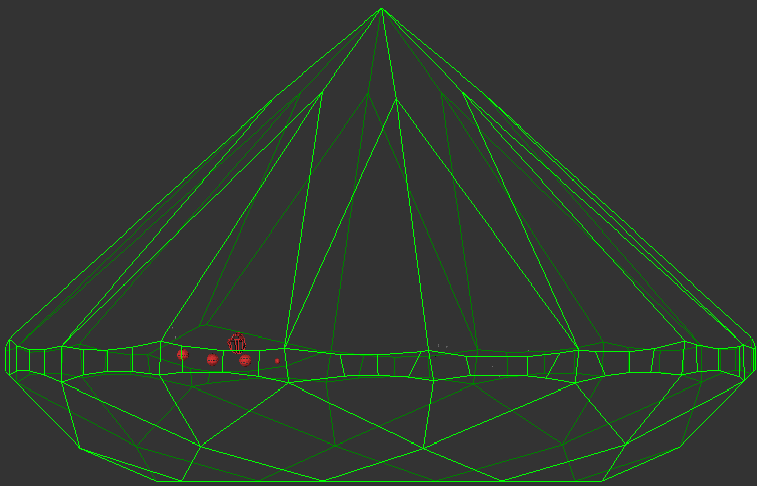

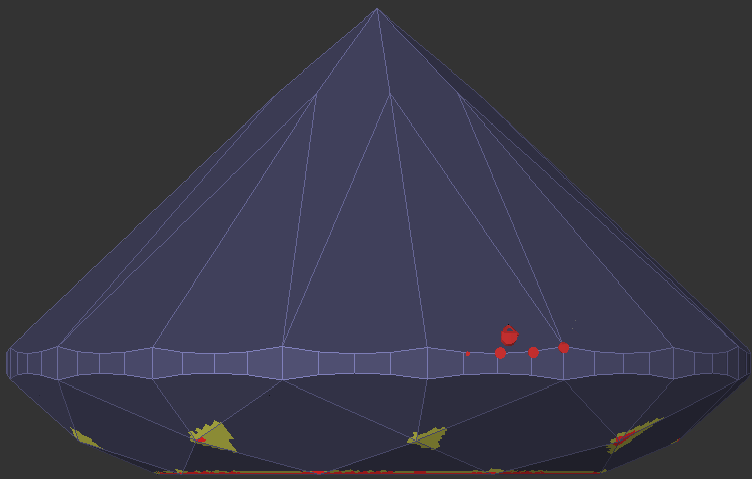

Extra Facets - Mechanism Improvement

For Smart Recut, the mechanism of how the girdle extra facets are created has been improved. The change is how the position of the extra facet is defined. The improved extra facet positioning function allows getting solutions with the larger mass.

Project: ef_101ct_test.ox2z, profile profile_test.txt.

Note Within the project:

- Gold Star - represents solution obtained manually

- No Flag - initial Recut solution

- Red Flag - solution obtained by Smart Recut with an old Extra Facet mechanism

- Green Flag - solution obtained by Smart Recut with a new Extra Facet mechanism

| Recut | Old Mechanism | New Mechanism | |

|---|---|---|---|

| Mass, ct | 0.9623 | 1.0057 | 1.0110 |

| Front Side | The old mechanism produces the extra facet of the lower size on the front side. | No extra facet here. The better extra facet is created on the back side. | |

| Back Side | The general limitation for number of extra facets will be 1. | In this example, an old mechanism does not see any potential for the extra facet creation on the back side. | Extra facet providing more mass increase is created on the back side. |

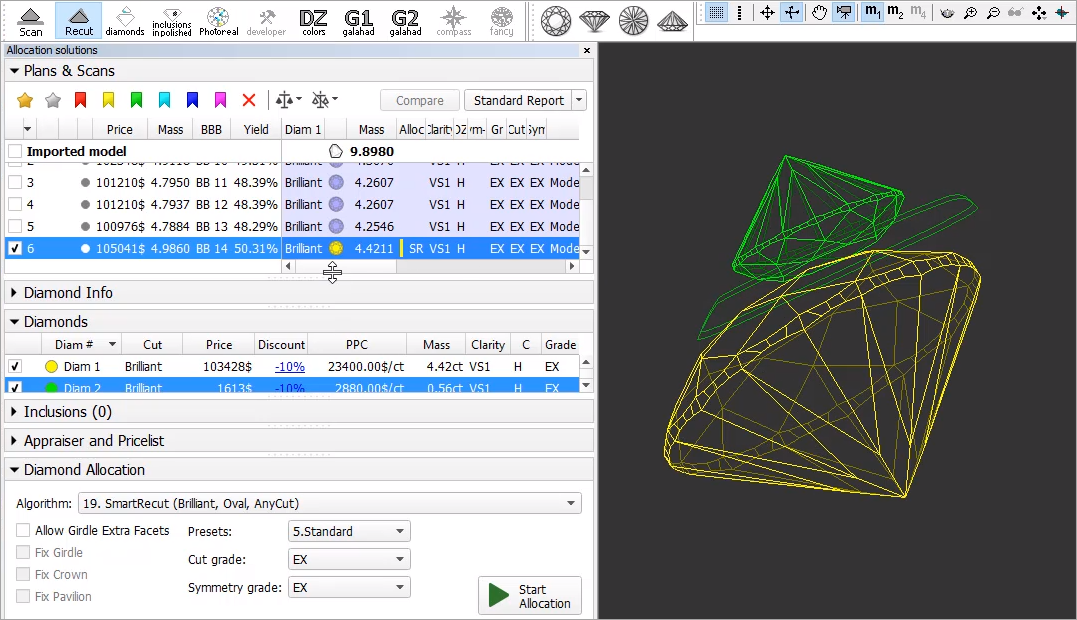

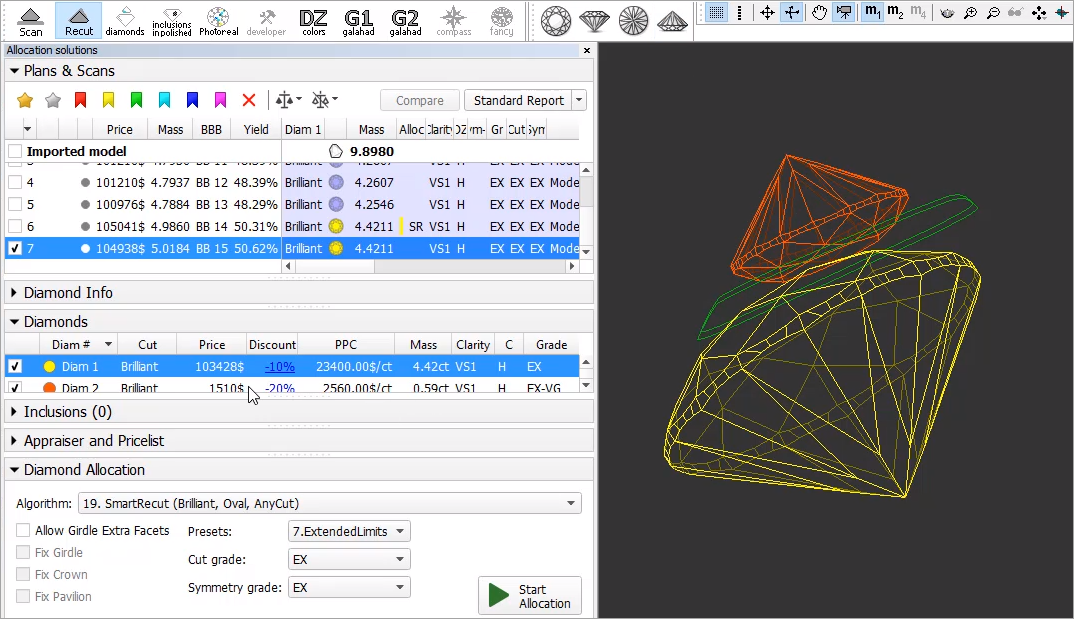

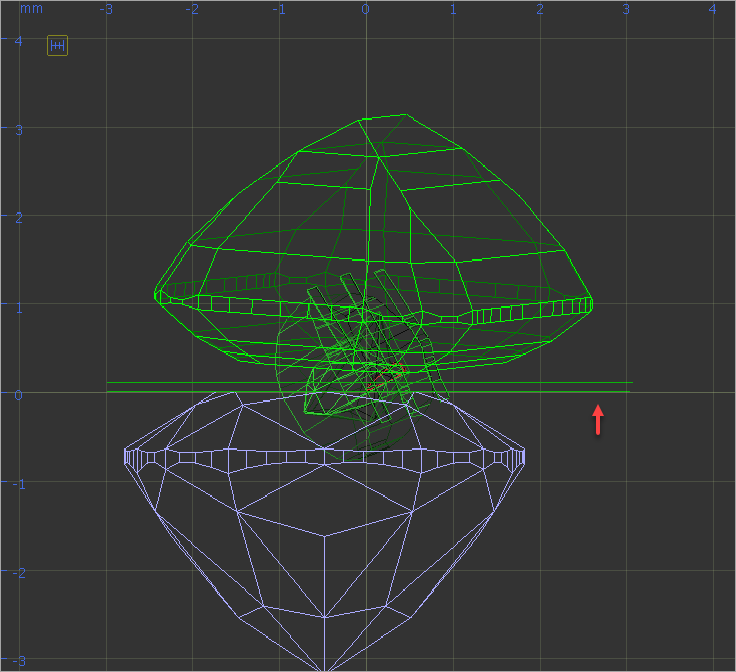

Using for Multi-Diamond Solutions from Rough

Notes

Options works only for RBC properly for a now.

Using Smart Recut for the multi-diamond solutions produced by the "13. Cascade-2M" algorithm from the rough stones is now made more user friendly. The work is now performed as follows:

- Open your rough model.

- Produce multi-diamond solutions with the "13. Cascade-2M" algorithm.

- Select the solution, select one of the diamonds inside it.

- Run Smart Recut. The new solution is added to the list. The previously selected diamond is transformed by Smart Recut.

- Select your newly produced SR solution, select the second diamond inside it.

Run Smart Recut again. The new solution is added to the list. Now both diamonds are transformed by Smart Recut comparing to the initial Recut solution.

While transformed, both diamonds still remain in their initial stone areas.

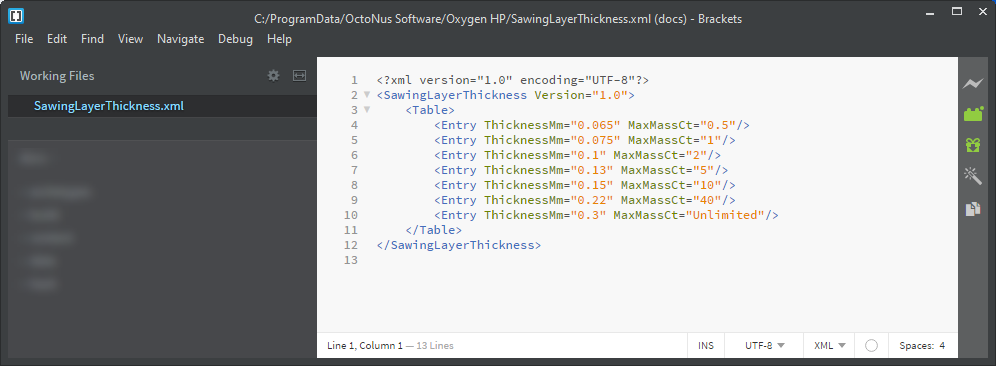

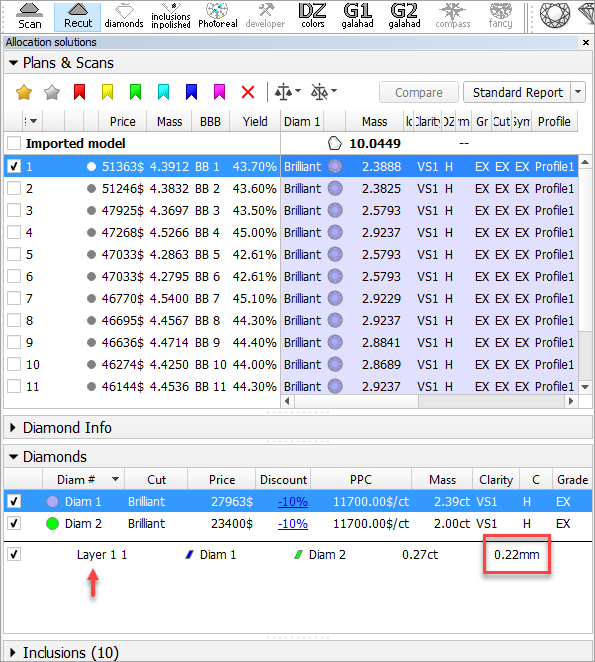

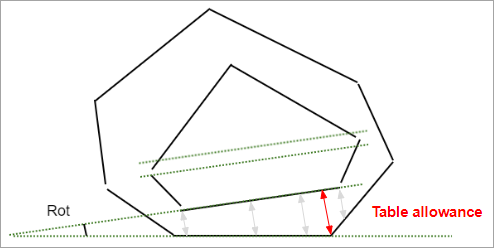

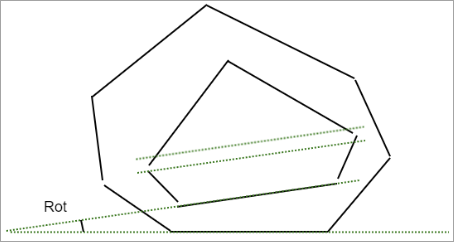

Cascade Algorithm - Configuring Sawing Layer

The "13. Cascade-2M" algorithm produces the solutions containing two diamonds and a sawing layer between them.

It is now possible to configure the thickness of this layer depending on the initial model mass. This can be done via the "SawingLayerThickness.xml" file, stored in the "..\ProgramData\OctoNus Software\Oxygen HP\" folder.

In HP Carbon, in the solution list, the Diamonds section for the selected solution (the solution includes 2 diamonds), the sawing layer is listed, its thickness in mm is displayed.

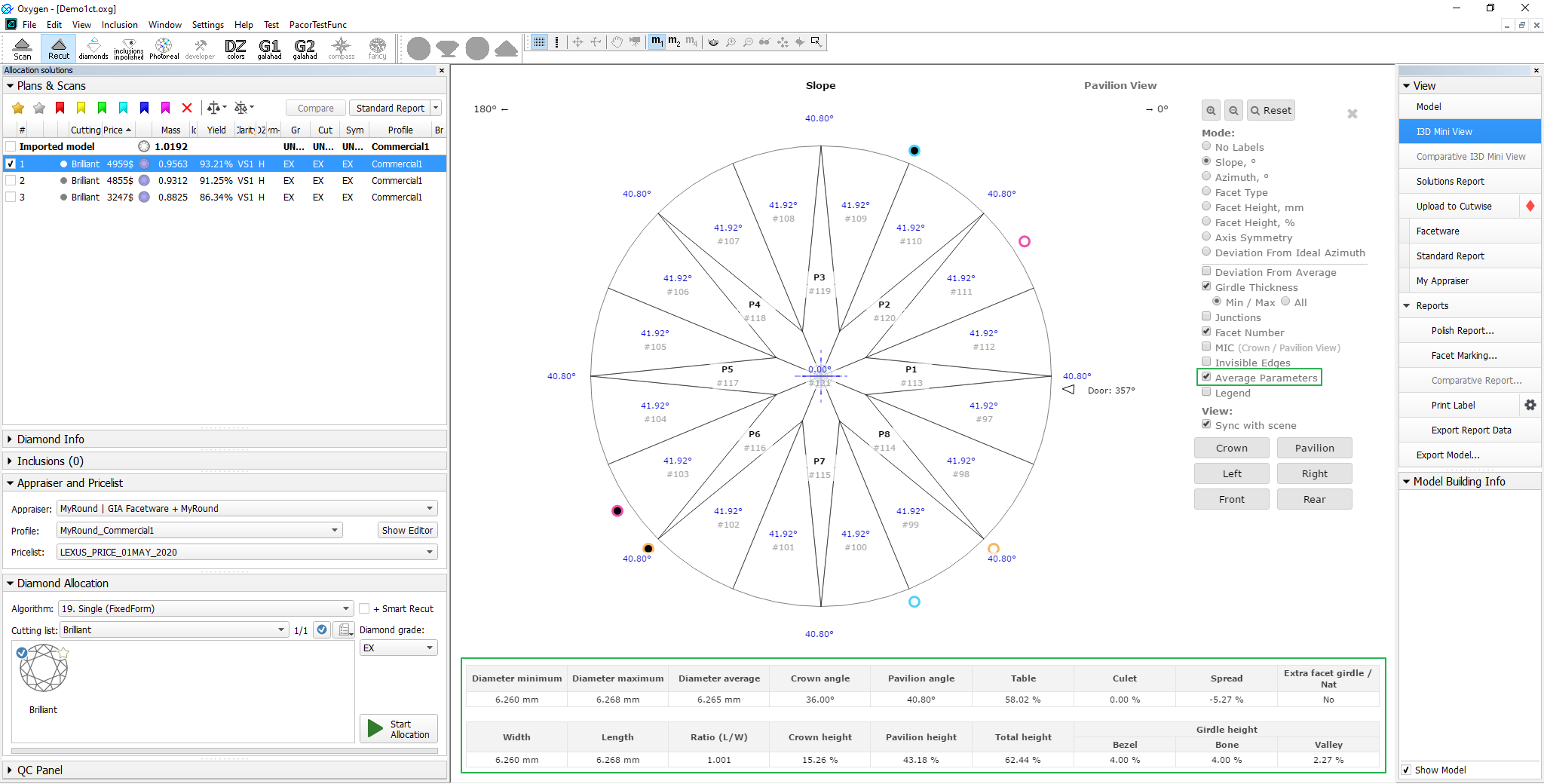

I3D Mini View - Average Parameters

In I3D Mini View, the Average Parameters table is now displayed by default (corresponding Average Parameters option is selected)

Standard Report - Displaying Grades for Cushion

In the Standard Report now, the grades for the Cushion cutting are displayed, including separately for Absolute and Relative parts of appraisers. This is available for the following appraisers:

- CushionRectangular_Opt

- CushionSquare_Opt

- MyAnyCutOpt appraisers

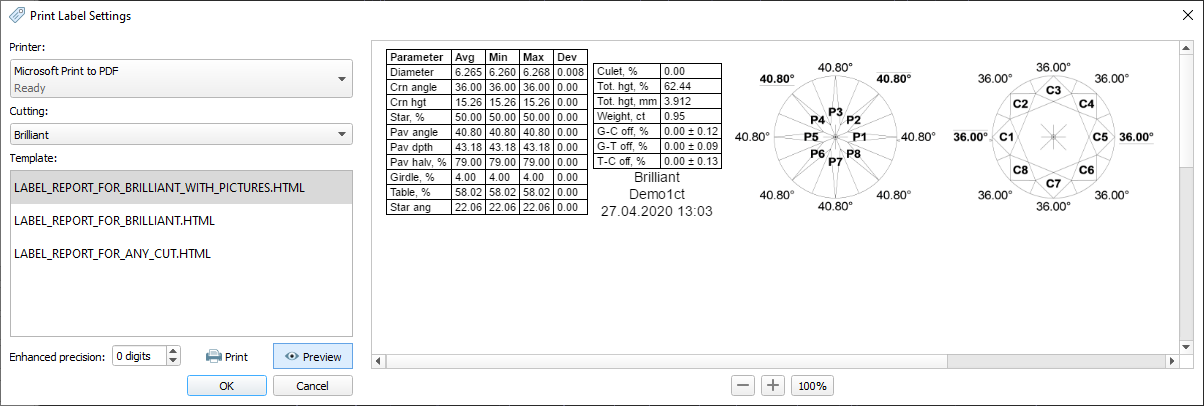

Embedding images in Label Reports

It is now possible to embed images in the custom templates for Label Report:

A sample template is planned to be included in the system in the nearest future.

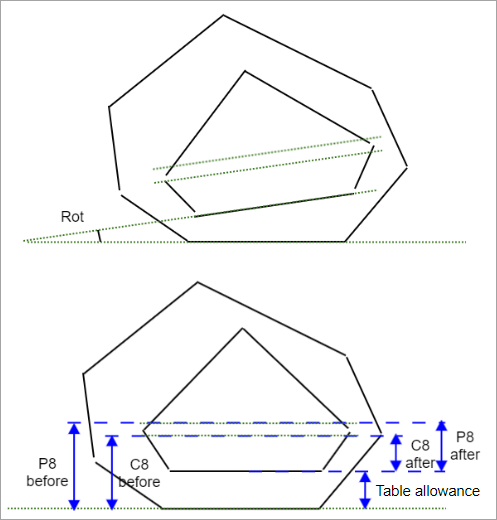

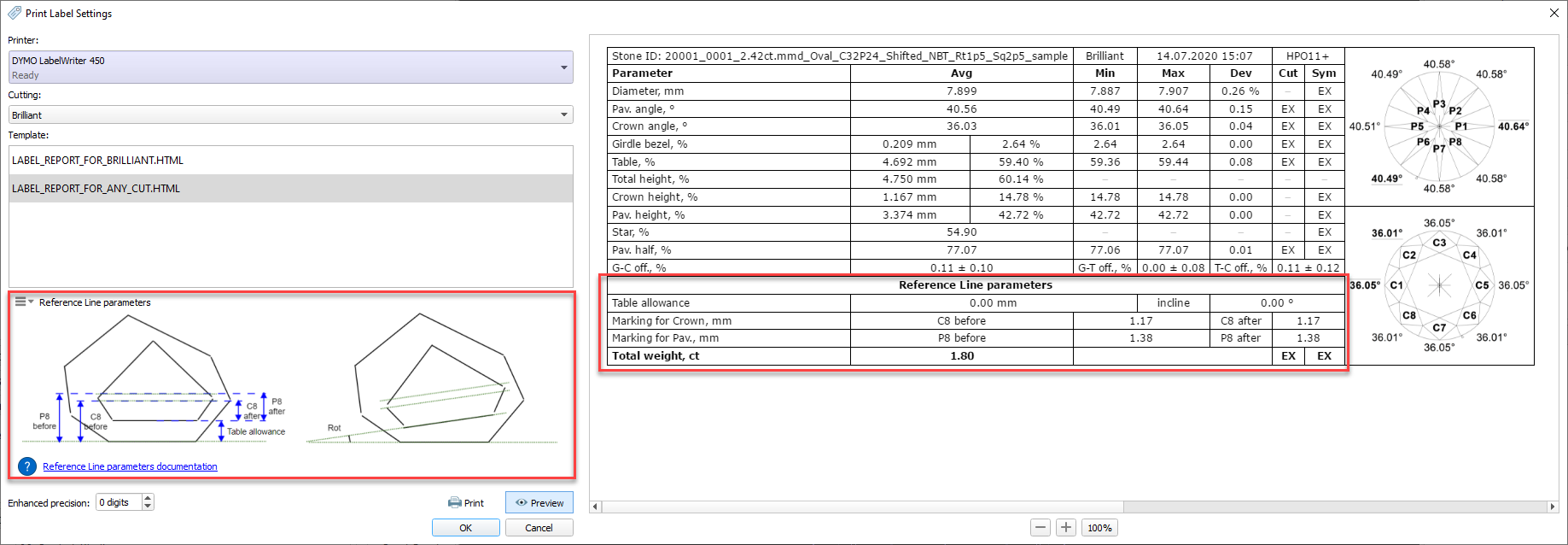

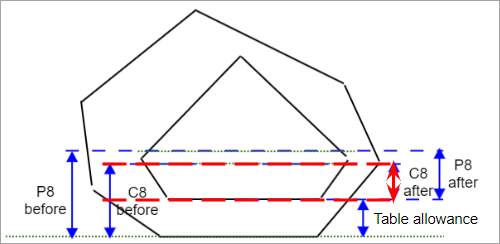

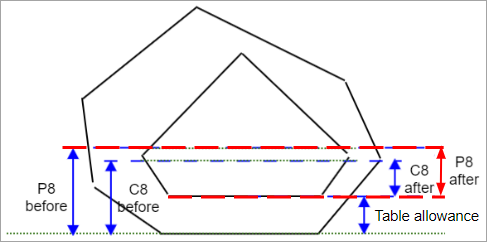

Print Label - Reference Lines Parameters

New parameters have been added to the Print Label report:

| Parameter | Description | Comment | |

|---|---|---|---|

| Marking for Crown - C8 before | mm | The reference line for the crown main facets before table allowance. | See the detailed description below. |

| Marking for Crown - C8 after | mm | The reference line for the crown main facets after table allowance. | |

| Marking for Pav - P8 after | mm | The reference line for the pavilion main facets before table allowance. | |

| Marking for Pav - P8 after | mm | The reference line for the pavilion main facets after table allowance. | |

| Table allowance | mm | Table allowance. | |

| Incline | deg. | Planned table tilt compared to the current table. |

Print Label example:

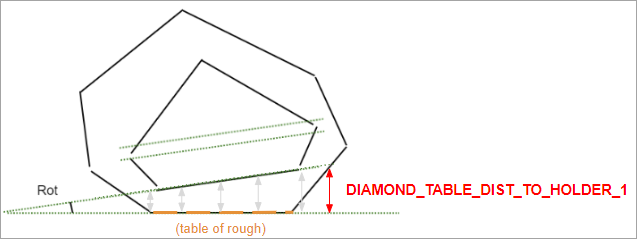

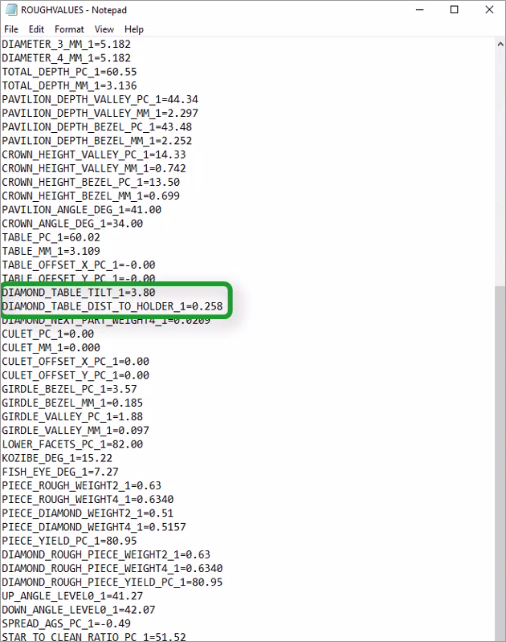

Rough Export - Table Tilt and Pieces Information Added

In the Rough Export results now the following information is presented:

Cut pieces of the main scan for the selected solution (including images)

This works fine both for the single and for multi-diamond solutions.

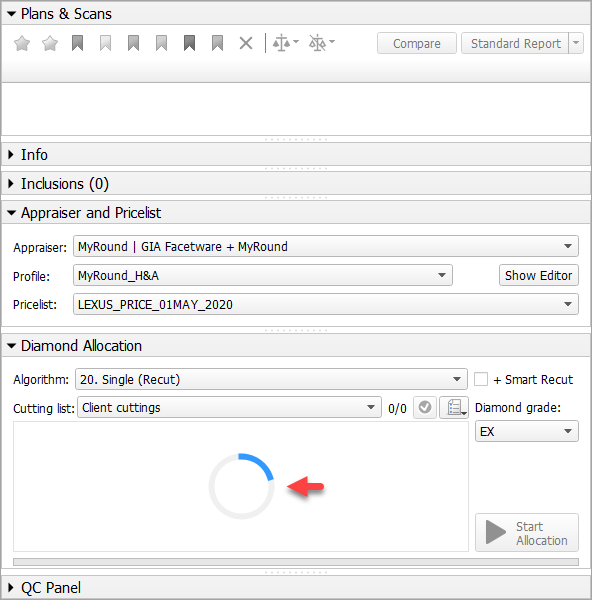

Cutting List - Loading Indication

On the system start, some time is required for all available cuttings to be loaded. Now the system indicates the loading process with the progress indicator:

As soon as cuttings are loaded, you can start using them.

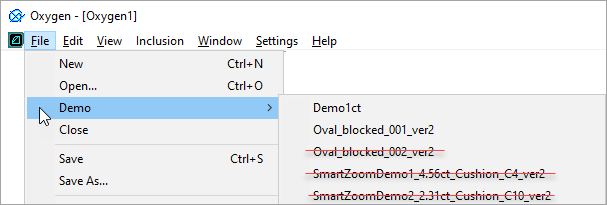

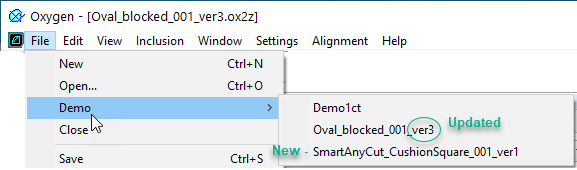

Demo Samples - Changes in Set

To make the set of the demo samples (available via File > Demo) be in more correspondence with the modern system usage scenarios, it has been changed:

| Was | Now |

|---|---|

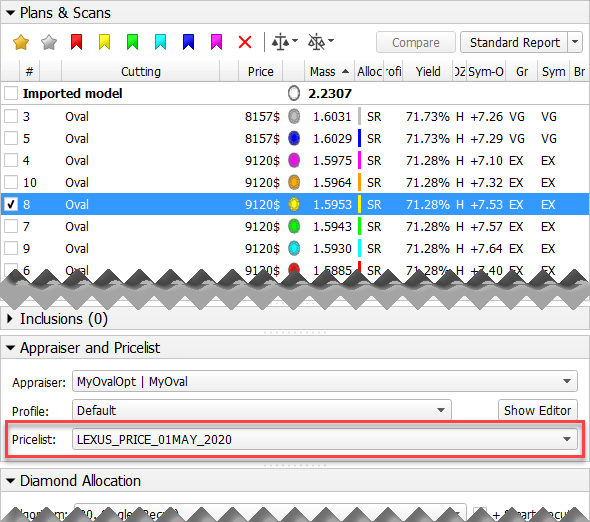

Updated Pricelist

The Pricelist is updated to up-to-date prices. The current pricelist name is "LEXUS_PRICE_01MAY_2020".

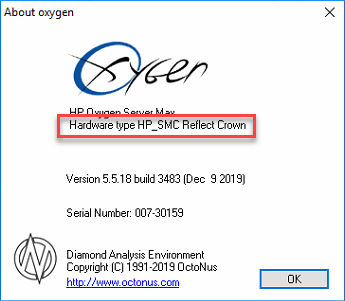

Hardware Type Detection

The system now automatically detects the connected board type. You can view this information via Help > About.

Firmware Update

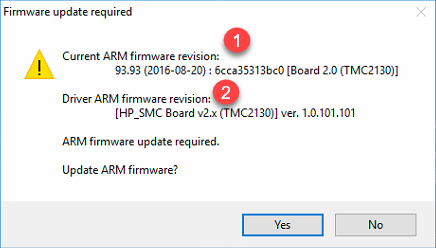

Now on the HPO start, the Firmware update required message will be displayed if the version of your board ARM component is not in correspondence with one required by the system.

On figure: 1 - firmware on your board; 2 - firmware required by HPO.

Required 1.0.101.101 is newer than current on the board 93.93.

Make sure the required firmware is newer than the current on your board and accept the update by clicking Yes. This will update the firmware of your board. If the HP Carbon software requires a firmware older than your board has, it is recommended to consult with an authorized person in your organization for further instructions.

See details on the Firmware Update Required page.

If you use several versions of HPO simultaneously with the HP_SMC v2.0 board, never accept the update to an older firmware when starting the older version of HPO. See the details in the "Using Current and Previous Versions of HPO Simultaneously" section of the Firmware Update Required page.

Preventing Unauthorized Access

HASP Protection

HP Carbon HASP ( Hardware Against Software Piracy ) protection has been further improved. This requires an upgrade:

- If you own the key version 4.x, its software part requires an upgrade.

- If you own the key version 3.x, you need to physically replace it with the 4.x with the latest software.

If you need anything mentioned above, please, contact your supplier of software or Octonus Support.

How to detect what key you have:

| HASP 3.x | HASP 4.x |

|---|---|

| No "silver eye". | Has a "silver eye". |

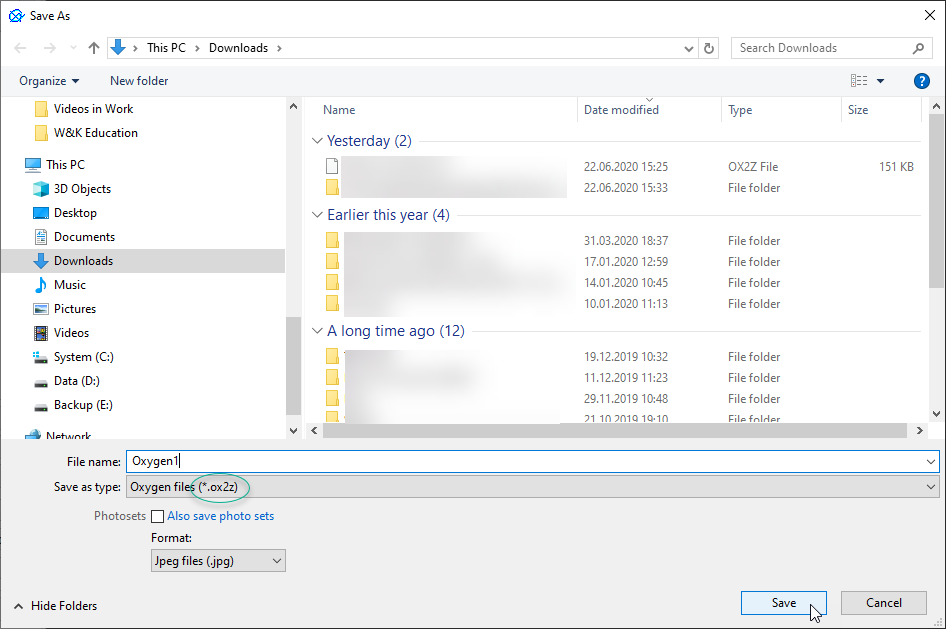

New File Format - OX2Z

The system now opens and saves projects in a new OX2Z format only. The previous versions of the system cannot open OX2Z files.

- In accordance with the described changes, the export of models and projects to other formats is restricted.

- You can open DMC and import the ASC files of the convex polished diamond models but not models of rough diamonds.

- You can open and import the DMX files.

Known Issues

The following issues are now being worked on and may be temporarily solved with workarounds:

- In some AnyCut cases, SweetLine prevents using FixCrown or FixPavilion. Workaround: to work with AnyCut FixCrown or FixPavilion set SweetLine boundaries to [-100, 100].

Fixed Problems and Improvements

The following fixes for the known problems and improvements have been implemented:

For the integration with Cutwise, multiple improvements have been made, including:

you do not need to install and configure a Cloud Uploader utility anymore - instead the new Cutwise agent utility is used, which is installed automatically (requires administrator password) together with HPO; before the first upload, you will need to enter your login and password to connect to Cutwise

now the following data is exported additionally:

solution price

- solution yield

- number of facets of brilliant

- now DZ light information is exported in the main bundle and Export Report Data TXT:

- DZ_PAVILION_COLOR

- DZ_PAVILION_CUSTOM_COLOR_GRADING

- DZ_TABLE_COLOR

- DZ_TABLE_CUSTOM_COLOR_GRADING

- DMCE (DMC-encoded) export for secured scan transfer

- DMX export

- Fix of the floating error that occurred during uploading of files with large quantity of solutions to Cutwise.

- now the standard trajectories of DiBox, ViBox (Girdle 360, Pavilion 360) for Cutwise virtual rendering are exported additionally

- Multiple Smart Recut improvements now reduce the number of solutions with an unreasonably small mass, except for presets with limitations stronger than Recut.

- Multiple Facet Marking algorithm improvements have been made, some minor bug fixes have been done.

- To match more accurately with the modern cutting standards, for the MyRound appraiser, for most profiles, the EX limits for the Table parameter has been changed to [54...60].

- The reports, available on Polish Report > Open HTML > "Illustrated report for ..." are now adapted for viewing on mobile devices. They are:

- Illustrated report for any cut

- Illustrated report for brilliant

- Illustrated report for cushion

- Illustrated report for princess

When working with Solutions Report and accidentally entering "0" or empty value for the Columns per page option, the report stopped working (black screen). It did not work after the system re-start either. Now this problem is solved: only the positive number from 1 to 50 can be specified for Columns per page and empty is not allowed.

- The problem with culet removed during Pavilion Model Refinement has been solved.

- The problem with SmartZoom and SmartRecut when working with the nonconvex facet has been solved.

- Crash on scan cancellation has been fixed - now scan cancellation works fine.

- The problem causing a system crash on Pear scanning has been solved.

Add Comment