Introduction

October release is a hotfix of a problem with inclusion shift. Also we have made automatic input data checking (background and HIG photos control) tougher.

Hotfix

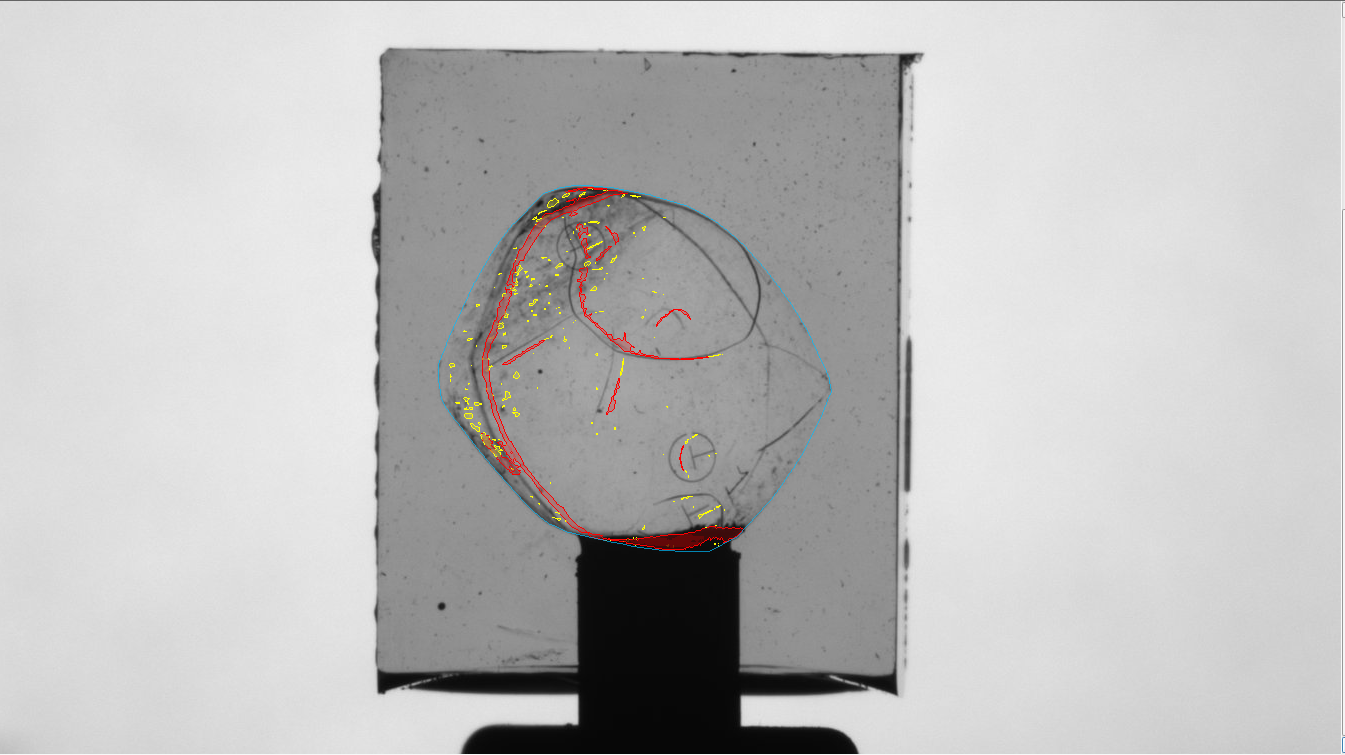

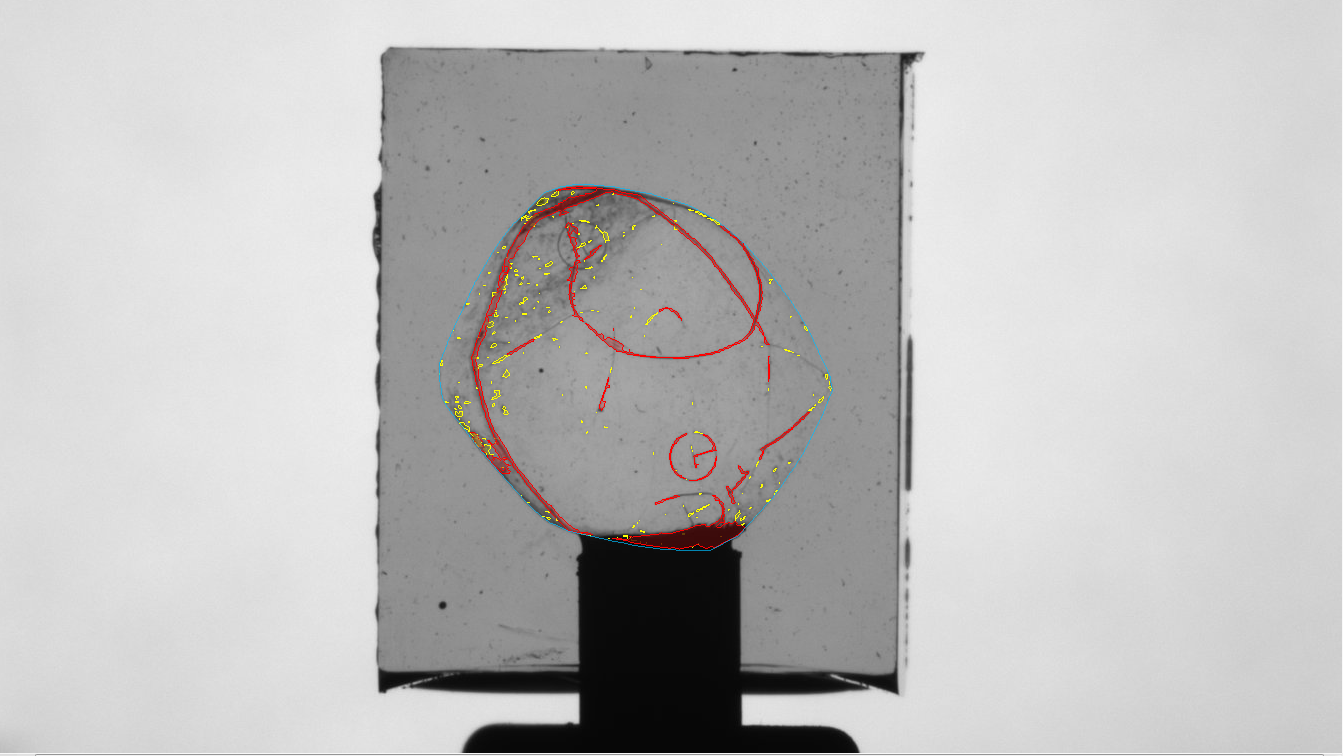

The main advantage of this release is a bugfix of inclusion shift problem. On the pictures below you can see the problem (left picture) and its fix (right picture).

Automatic input data checking

In this release we improved the system of automatic input data check to discard badly acquired data. Bad input data often is a reason of poor autoplotting results.

Note that automatic input data checking works at the beginning of autoplotting algorithm (not during data acquiring). If the input data is bad the autoplotting algorithm terminates with a error, and you have to obtain new HIG and background photos.

So the input data check procedure defends the autoplotting algorithm from wrong data (and tells you the reason of the error), but it doesn't help you to avoid it during scanning. That is why, during scanning you should follow these simple rules:

- Before and after background must be similar. Usually these images differ if you adjust exposure after you have already scanned the before background.

- The background must not be overexposed. Normal background brightness is about 200 of 255 (maximum - 220) in center of shot .

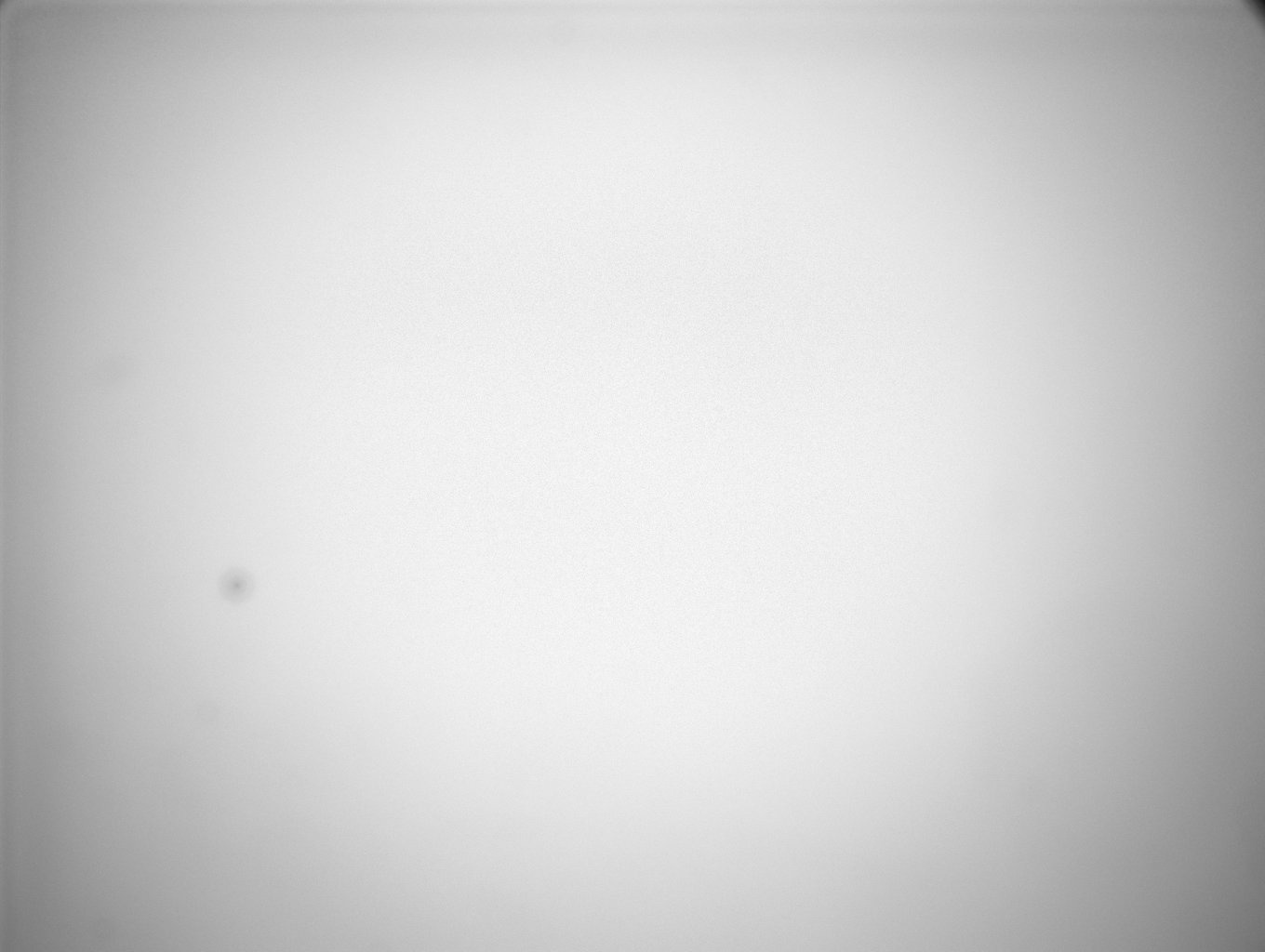

- The background must be uniform. On the pictures below you can see the example of non-uniform background (left) and uniform one (right).

4. In the area outside the immersion cube the difference of HIG photo and background must be small. This difference is big if during scanning there were some changes in lighting conditions (for example, someone opened the HIG cover).

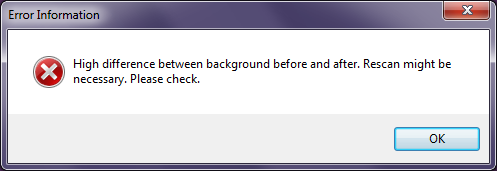

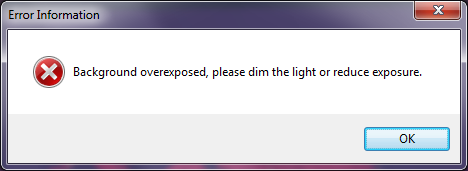

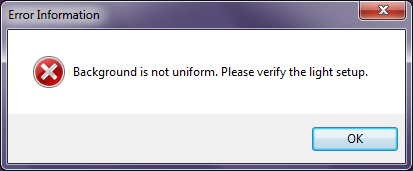

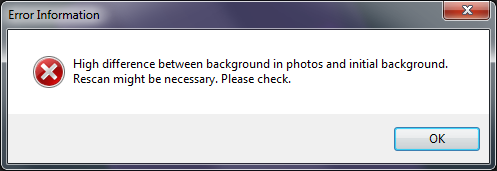

The automatic input data check algorithm may terminate with following errors:

- Two background images (before and after scan) do not match - the rule #1 was violated. Check the exposure. Make sure that the light setup elements do not move during the scan and the LED brightness does not change. And rescan all photos.

- Too high background brightness (rule #2). Normal background brightness is 240-245 of 255. In this case, decrease the exposure.

- High difference between the most bright and the most dark part of background (rule #3 violated). Normally, the background should be uniform. This problem can be solved only by engineers. They have to make HIG background more uniform by changing the lighting system.

- This error occures if the area outside the cube and it does not match the initial background (rule #4). This means that some changes in the lighting occur when the glass cube is installed: opened HIG cover or reflected direct LED light from the glass or holder may be the reason.