Here you can find information about what is new in HP Carbon version 1.5.3.

Public

Executive summary

There is continuing growth of interest in fancy diamonds in such specific markets like India and the West. It is expected that consumers in the key Asian markets will follow the trend quite soon. Our goal is giving our clients the opportunities not just to supply the new demand smartly but also to build robust long-term positions with development of their distinctive signature products in fancies in a very commercially efficient way.

With the current release we offer manufacturers a unique chance to consistently build all-company's in-house know-how to make best performing fancies with bigger yield. With every successful cut highly appreciated by sales team and consumers, the aggregated company’s knowledge expands and provides more winning options for the future cut searches. Important that starting from this release the models’ parameters are kept secret, so, nobody can copy them from your company’s database.

Before this release

Polishers always used available technologies and tools in the best possible way. The combination of Smart Recut, X-ray and Compass technologies provided great results for round shapes at the semi-polished stage because of the relatively limited number of parameters which describe an RBC.

The situation was quite different for fancies. The fancy shapes optimization algorithms provided solutions which were used to estimate Carat weight of future stones (to set target weight).

These solutions could not be effectively used as a direct Galahad plan for the following reasons:

- It was almost impossible to create DLL cuts with a large number of parameters because of the huge diversity of cut patterns.

- Because of this, manufacturers were forced to use ASCII cuts that had a very limited set of parameters that included just Crown and Pavilion heights, but not slopes (for example, in ASCII cut it is not possible to control the slopes for different pavilion tiers).

- With such ASCII cuts parametrization, it was impossible to obtain the maximum weight for those combinations of proportions that the client considers optimal in terms of the cut quality.

Usually, polishers finally worked out how to get more out of the stones on the basis of the recommended solutions (deciding on Slopes and Azimuths of facets). They considered a certain Crown-Pavilion range around the centers of recommended solutions. So, the result (Diamond Carat Weight and Performance) significantly depended on polishers' skills: every polisher built his mastership, but this experience could be hardly used by other colleagues and was doubtful to become the company's long-term asset.

After this release

The new release offers a new format of fancy cut description/identification: it is possible now to change not just the height but also every separate angle. The models appear now in a “multilayer” mode, which allows to change every layer independently. This gives more freedom and potential to the search of the best performing proportions.

Successful models found by polishers or as results of in-house Cut Evolution projects are to be stored in an aggregated in-house database to be used in the future optimization searches. So, with every successful model company builds its expertise incrementally. Important that for the commercial security reason the saved models will be used by optimization algorithms only, they are protected in a way that they cannot be extracted from database as sets of parameters.

In-house cut appraisers define deviation ranges for selected successful in-house models. In this way company builds own multidimensional space of recommended models with corresponding appraisers. The natural selection process guided by choice of sales team and consumers results in survival of the best spices. No bad stock with high discounts anymore. The best cut pedigrees make up the golden fund of your company, its highly valuable intangible asset, which consistently brings tangible sales and orders. Your skillful polishers contribute to in-house database, but your company does not depend on every polisher so much anymore because their craftmanship is continuously accumulated for future in-house usage. Even novice polishers can deliver great results based on in-house stored expertise.

In-house cut allocation takes place in the following way:

- Optimization algorithm picks up the best suitable cut combinations from in-house incremental database.

After this apply all allocation forms to find the best solution for every Rough/Semi-polished stone and optimize within a range of parameters (including Crown slope and Pavilion slope in new introducing Goodwin type of cut) according to in-house cut appraisers.

Such optimization selects solutions with maximum mass and performance close to actual proportions that were already polished in-house and approved by the sales team. These solutions are designed for direct execution by Compass.

This approach provides company management and sales team with effective tools for directing and controlling polishers’ job in order to reach the lucrative market segments and avoid bad stock and huge discounts.

Start to maintain the cycle of continuous building and improvement of your company’s in-house incremental database right now. Every successfully polished stone secures future company’s position in this highly competitive market. Secure your market share with your signature in-house cuts.

Technical details

There are more detailed description of new important tools and features of the release:

GOODWIN CUT. PROCESS FLOW

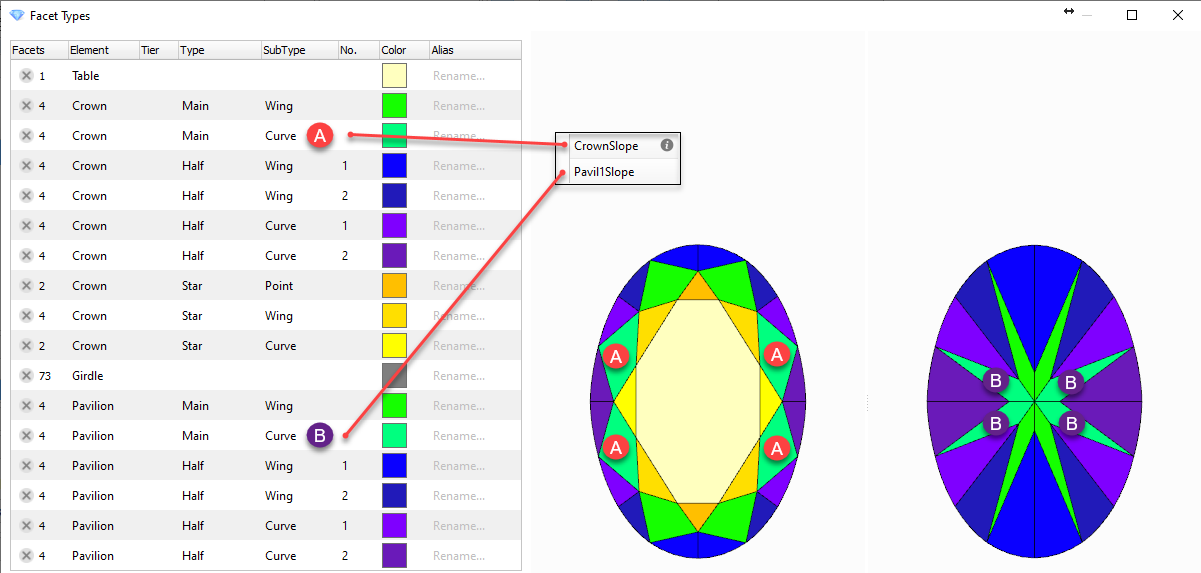

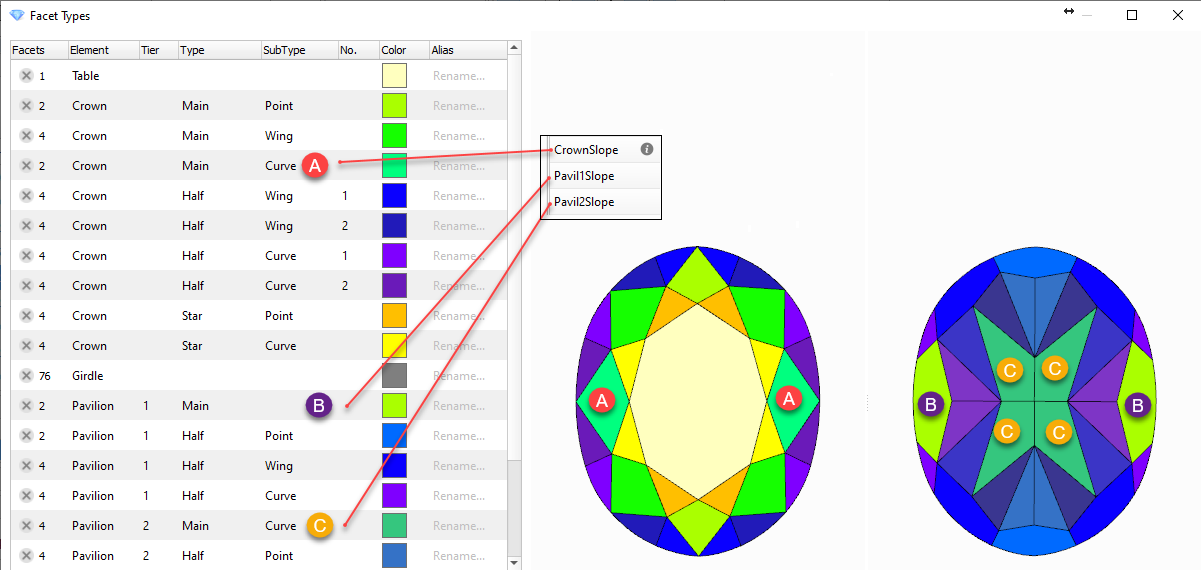

Goodwin cut is an advanced type of in-house cut which compared to the previous generation of cuts (aka ASCII-cuts) has more precise control over the cut geometry when changing the parameters, and also allows controlling the slopes of main facets.

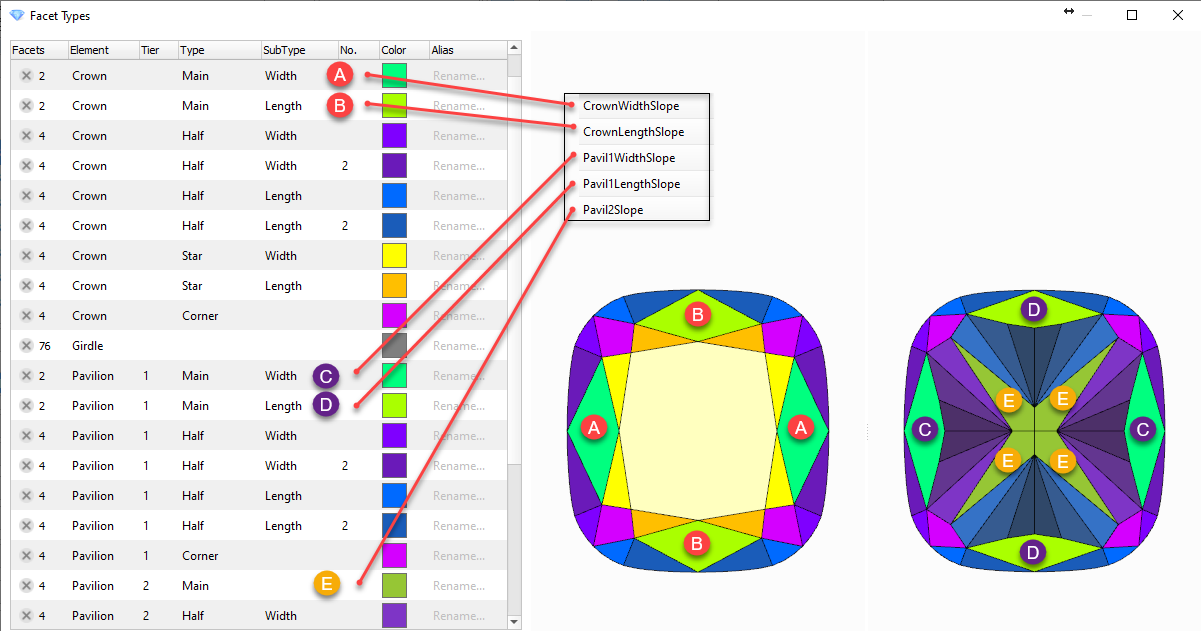

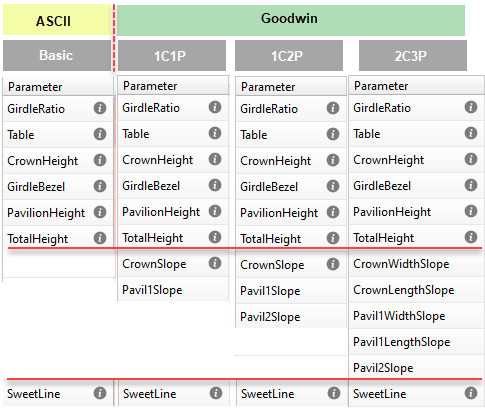

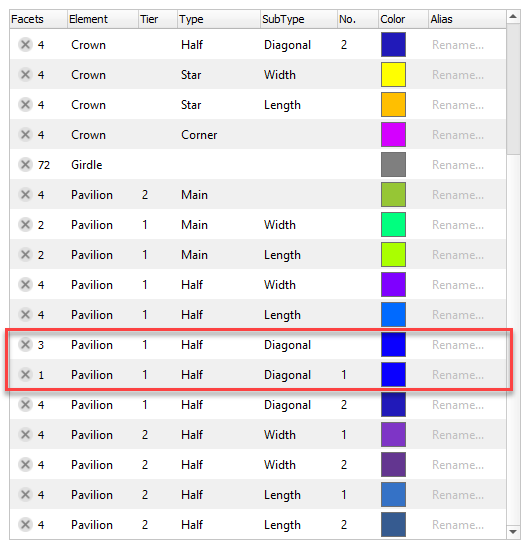

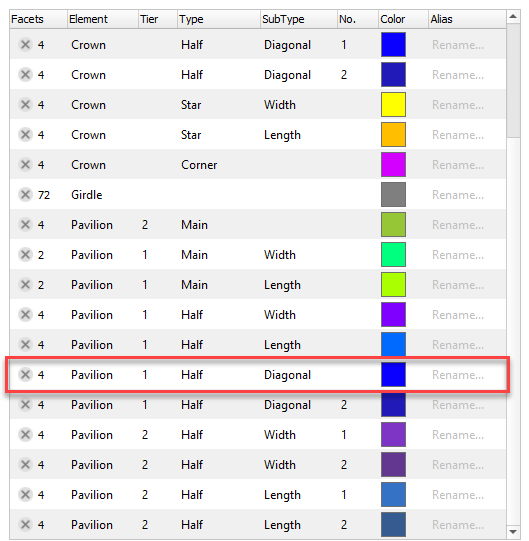

Control angles for in-house cuts

To achieve excellent optical performance for in-house fancy shape cuts, it is necessary to control the Crown slope and Pavilion slope parameters, SweetLine parameter of your models.

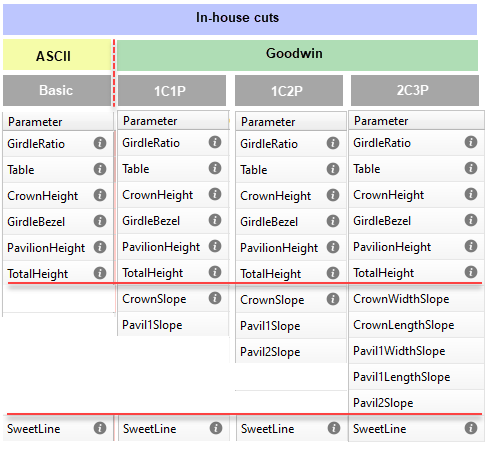

Previously registered new in-house cuts could be only of ASCII type (limited set of parameters) - now you can select a new in-house cut to be of the Goodwin type. In addition to ASCII parameters, for such cuts, you will be able to control:

- Crown slope

- Pavilion 1 and 2 slopes

- For rectangular cuts - these slopes along width and length

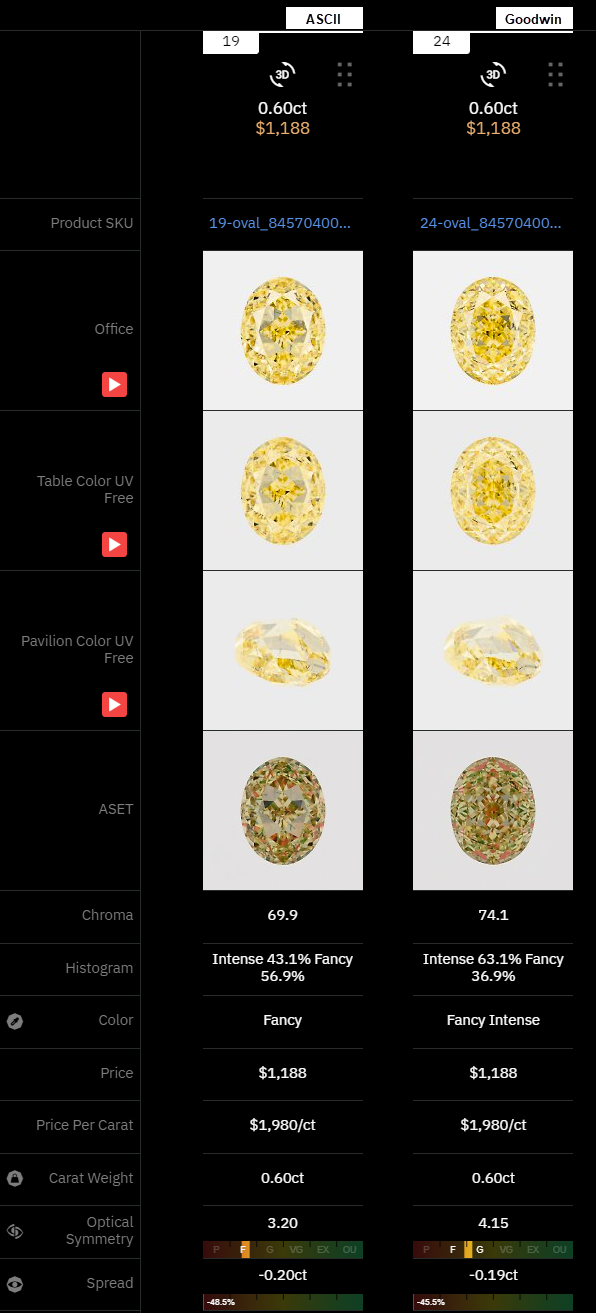

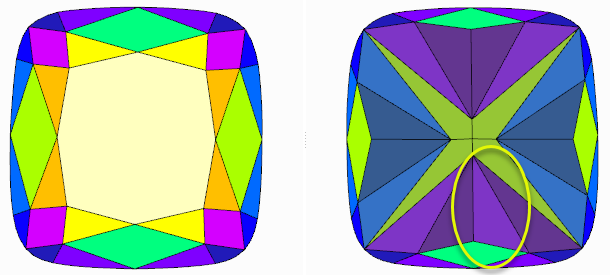

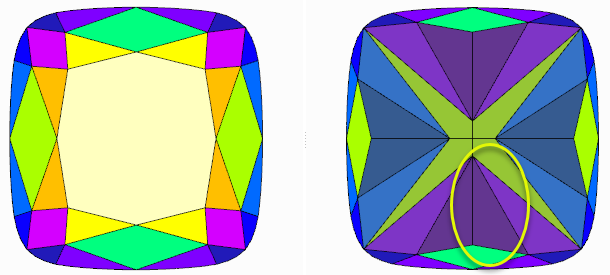

Below is an example of the benefits Goodwin type cut provides comparing to ASCII:

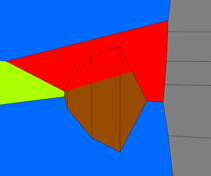

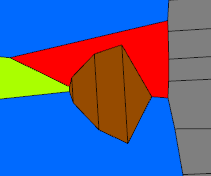

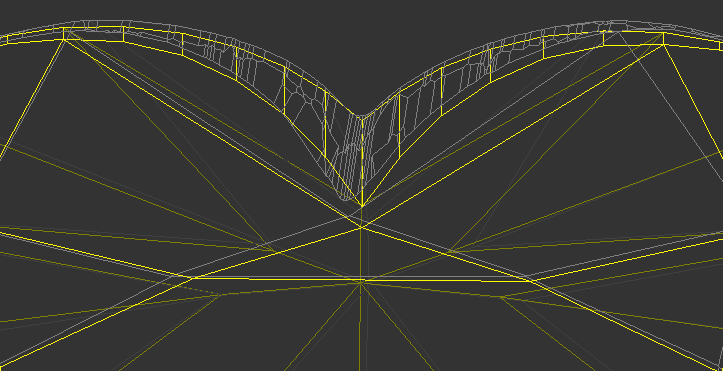

SR with ASCII produced bigger windows which makes them actually unacceptable. Goodwin model does not contain such windows due to control over angles. This is also reflected by metrics. |

Example

See this example details in the Goodwin fancy color example article.

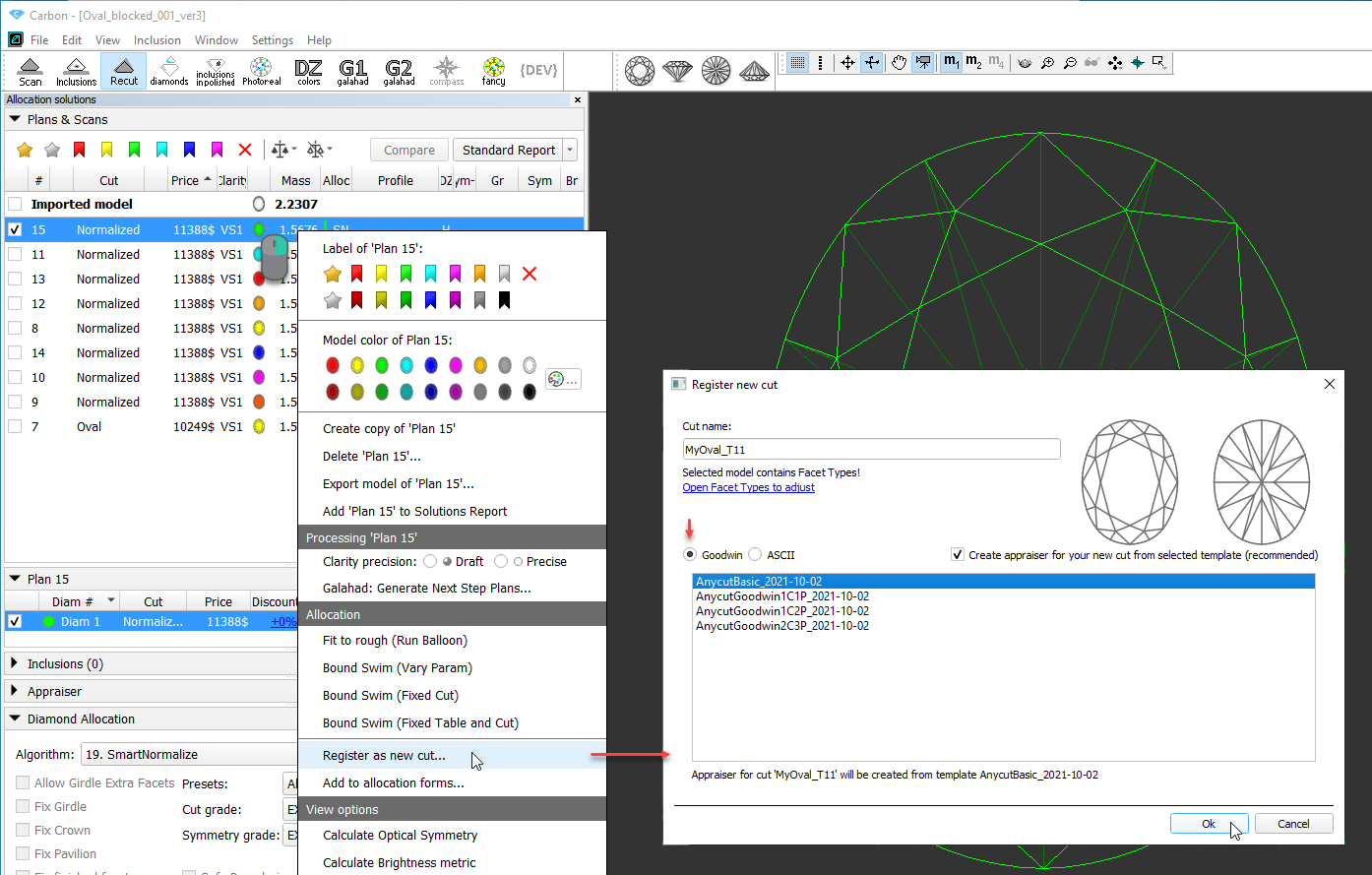

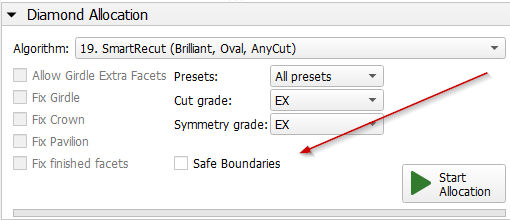

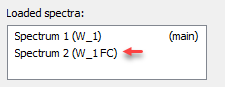

To register your model as a new cut of Goodwin type:

- Make sure your model has the appropriate facet types.

- Normalize your model.

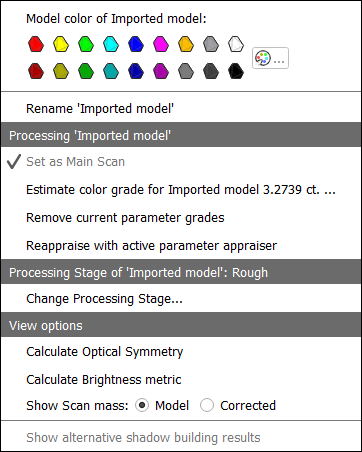

In Plans & Scans, right-click the best normalization result* and then, from the context menu, select Register as new cut. The Register new cut dialog is displayed.

* Usually, the "1. High_Sym_CFM" Smart Normalize preset (magenta colored) provides a result most suitable for further registration as a cut.

- In the Register new cut dialog, specify Cut name.

- Select the Goodwin option.

- Make sure, the Create appraiser for your new cut from the selected template (recommended) option is selected.

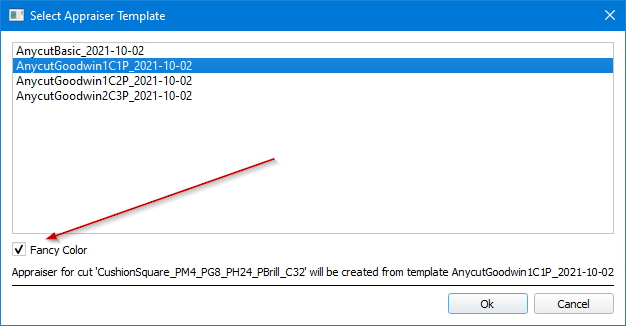

In the list, click the appropriate template.

Which template to choose?

Template Description Cut sample* 1C1P For cuts having 1 tier for a pavilion. Allows controlling one angle of a crown (1C) and one angle of the pavilion (1P). The template is suitable for most cuts. 1C2P For cuts having 2 tiers for a pavilion. Allows controlling one angle of a crown (1C) and two angles of the pavilion (2P). 2C3P For rectangular cuts with 2 tiers for a pavilion. Allows controlling:

* separately of two angles of a crown (2C)

* three angles of the pavilion (3P):

* two on the 1st tier of a pavilion

* one on the 2nd tier of a pavilion* Note that if you have several "Main" groups on the same Tier but different SubType, the priorities are used to define which group will be controlled by the parameters.

Goodwin type cuts support AnyCutBasic appraiser as well, but with the lack of important advantage of having slope angles in the appraiser.

Note that selecting a template is not enough - later you must edit profiles manually.

Click Ok.

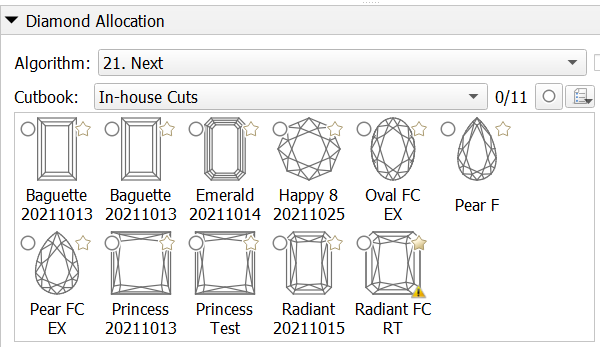

The new cut of the Goodwin type is created. It is added to the Diamond Allocation section, Cutbook > in-house Cuts. Also, from the selected template, a new hybrid appraiser is created for this new cut.Important

This is not the end, but just the beginning of the process. The next two "big steps" are obligatory to make your new cut/appraiser work effectively. The details about why it is important to populate a cut with the allocation forms and set your own boundaries for the linked hybrid appraiser you can find in the In-house cut registration, Hybrid appraisers, and related articles.

- Add allocation forms to your cut.

Edit the boundaries of your appraiser profiles.

It is recommended to coordinate set boundaries of your appraiser with the allocation forms:

1. Select Manual appraiser selection.

2. Set the Appraiser and Profile to the one you are editing.

3. In the Diamond Allocation section, Cutbook > In-house Cuts, right-click your cut and select Show allocation forms. In Plans & Scans, allocation forms are displayed. They are graded by your appraiser/cut.

4. Make sure, grades are EX. If not edit the boundaries and repeat the estimation or consider deleting some forms.

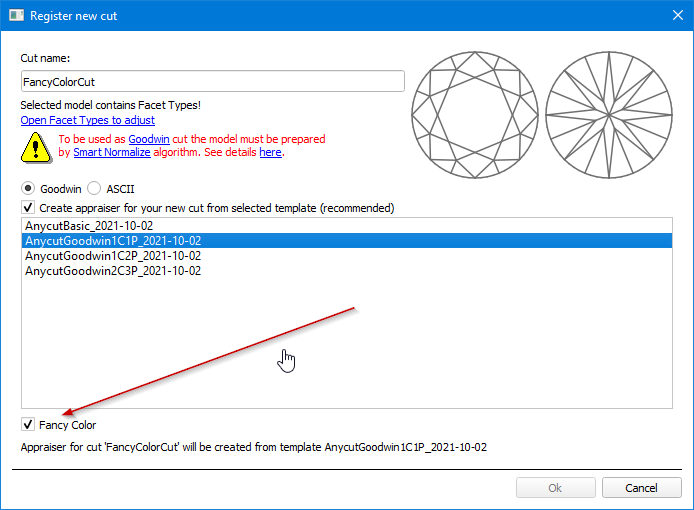

Аutomatic adjustment of appraiser intervals for in-house cut to set start allocation form to EX group

During in-house cut registration program creates appraiser with parameter intervals from the selected template. Start allocation form which is used for cur registration could be out of EX group by some parameters.

There is new feature in software to adjust automatically intervals "Absolute Proportions" to set start allocation form in EX group that is required for correct work of further allocation.

The intervals adjustment is following: intervals from templates are shifted on the some value of parameters ("parallel shift" for parameter intervals of EX, VG, GD, ... groups). The value of the shift is found by software by such way that value of each parameter is exactly in the middle of EX group. Therefore all values of start allocation form are set in the middle of EX group. Intervals size [min, max] for each group are remained the same as in template.

| Intervals before adjustment | Intervals after adjustment |

|---|---|

Integration with Cutwise

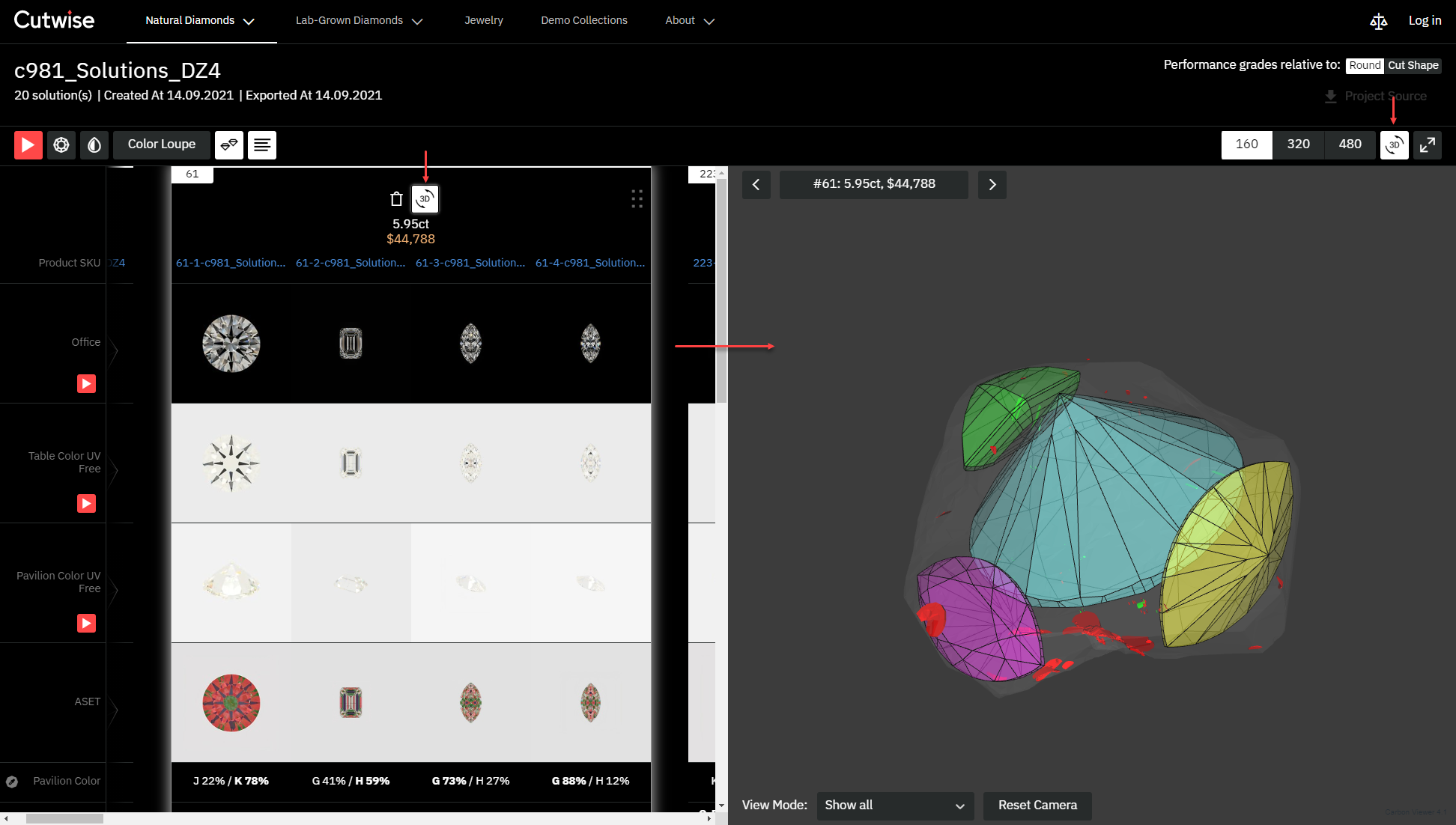

View solutions in 3D interactive space

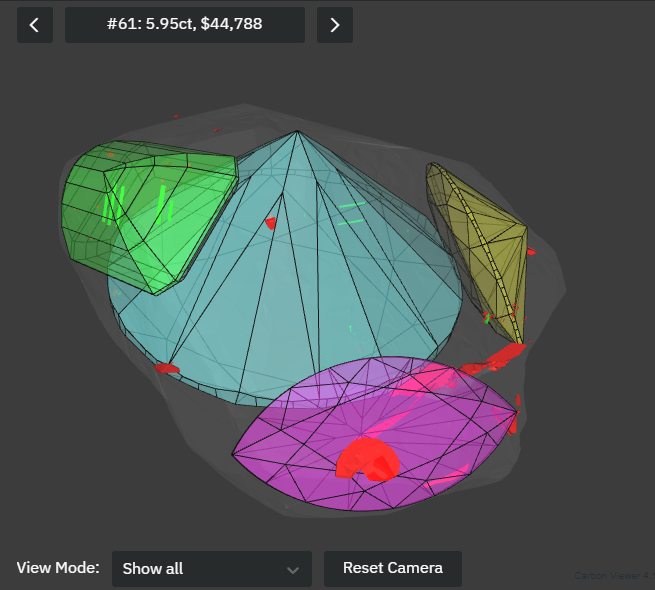

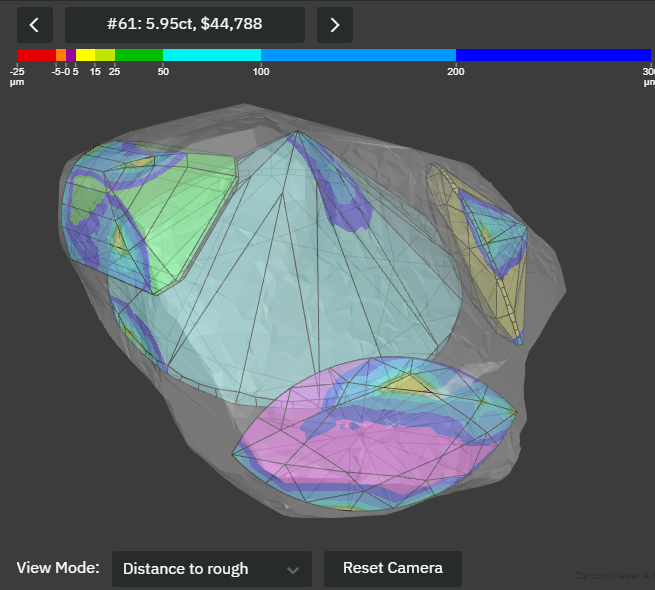

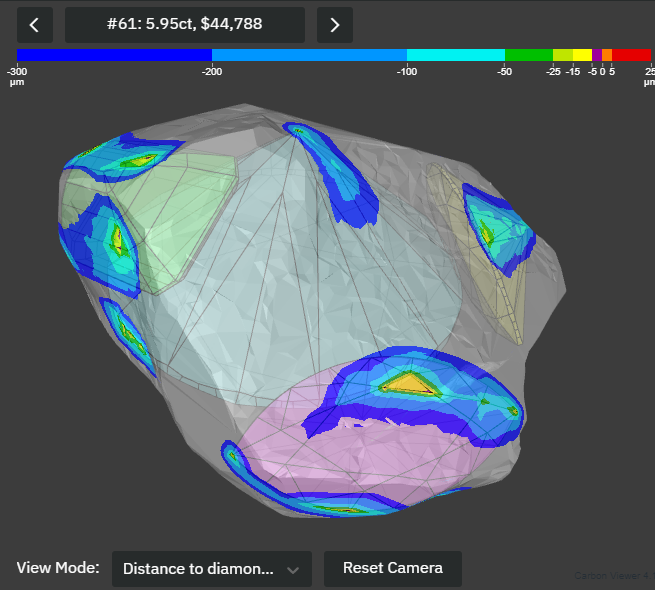

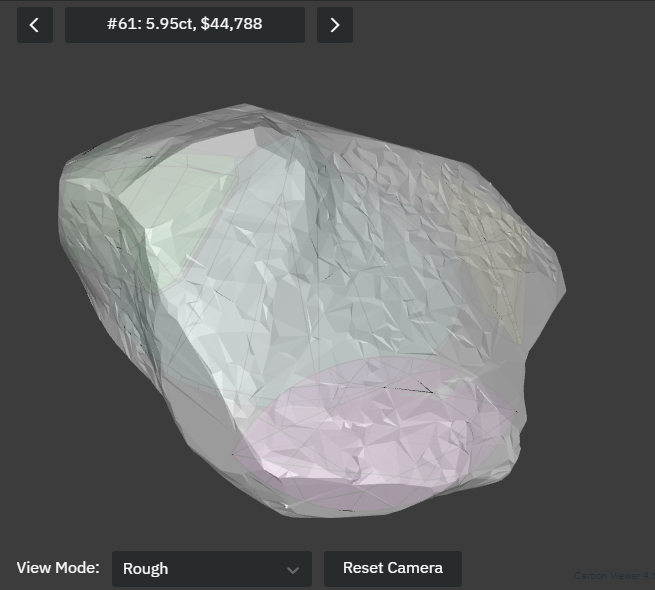

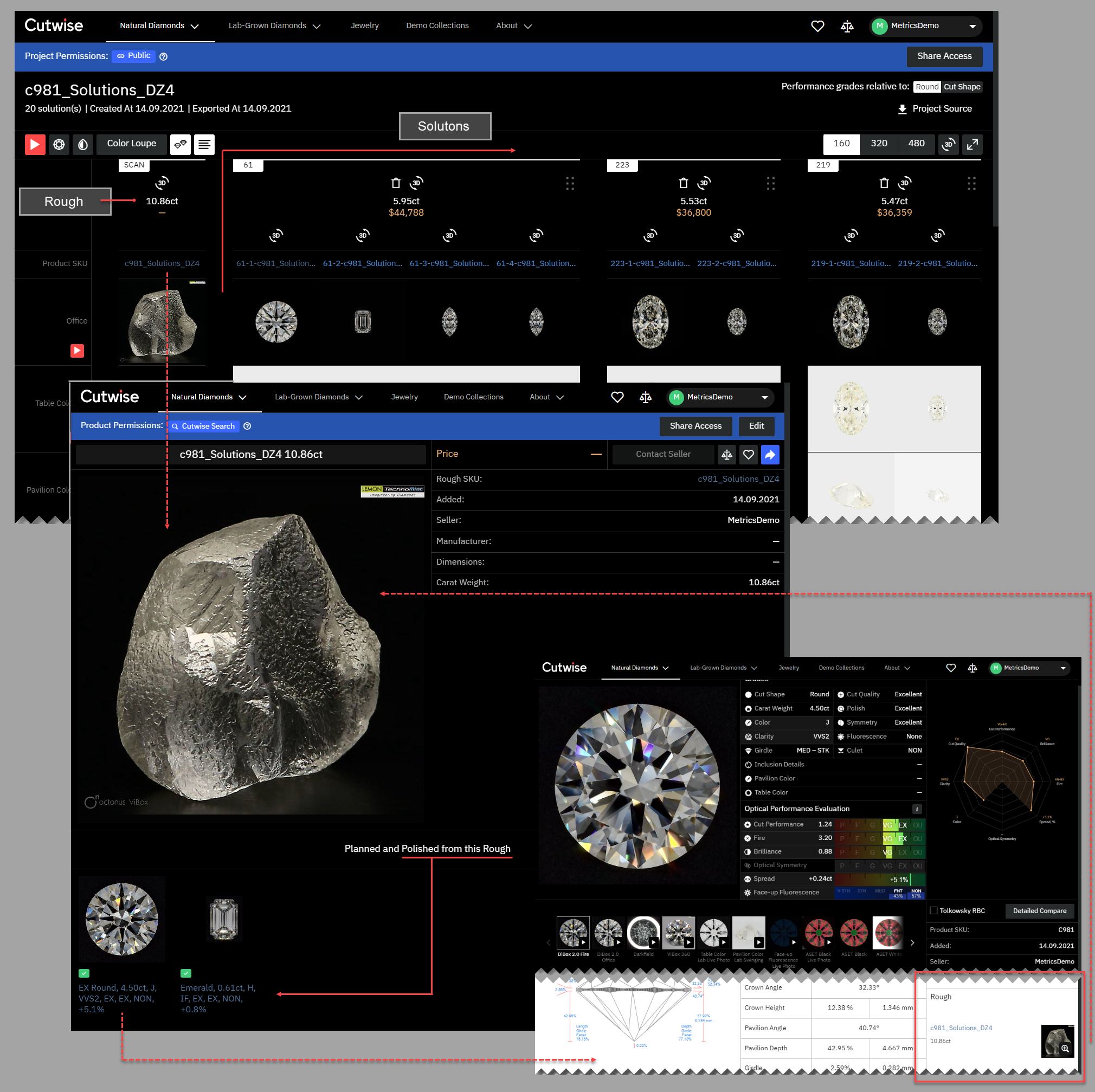

Cutwise online service integrated with HP Carbon allows quick sharing via the Internet information about polishing plans (solutions), including renderings of future stones, indistinguishable from the real DiBox2 films for both Round and Fancy cuttings. Now in addition to visual and parametric representation of plans, Cutwise is able to present solutions in 3D interactive space (like Scene in HP Carbon) - Carbon Viewer.

Thus, full information about plans ( parameters + media + interactive 3d model ) now can be easily shared with the remote team members (polishing experts, managers, sales specialists) or customers. The Carbon Viewer provides full and interactive information about:

- number, size, and position of inclusions

- how diamond(s) is positioned relatively to rough and inclusions; if several diamonds in a plan - how they are positioned relative to each other

- distances between rough, diamonds, and inclusions

To view solutions in Cutwise 3D interactive space:

- In HP Carbon, use the Upload to Cutwise feature.

- In the Cutwise project, related to the uploaded data, on the project toolbar or for a particular plan, click . View button becomes active , 3D interactive space (Carbon Viewer) is displayed.

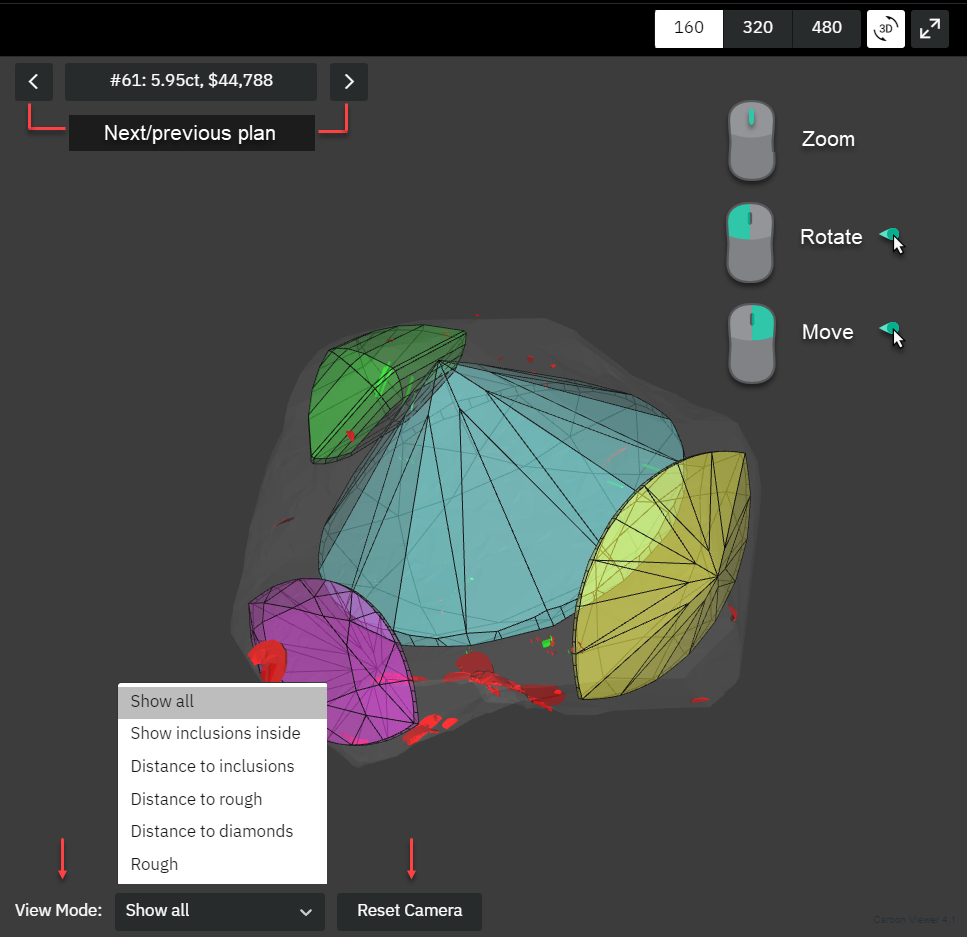

What can you do in the Carbon Viewer window

- Switch View Mode

- Switch to the next/previous plan

- Reset camera

- Zoom with the scroll mouse button

- Rotate a model with the mouse (hold left + drag)

- Move a model with the mouse (hold right + drag)

Modes

The table below describes available view modes:

| Show all | Shows:

Notes

| |

|---|---|---|

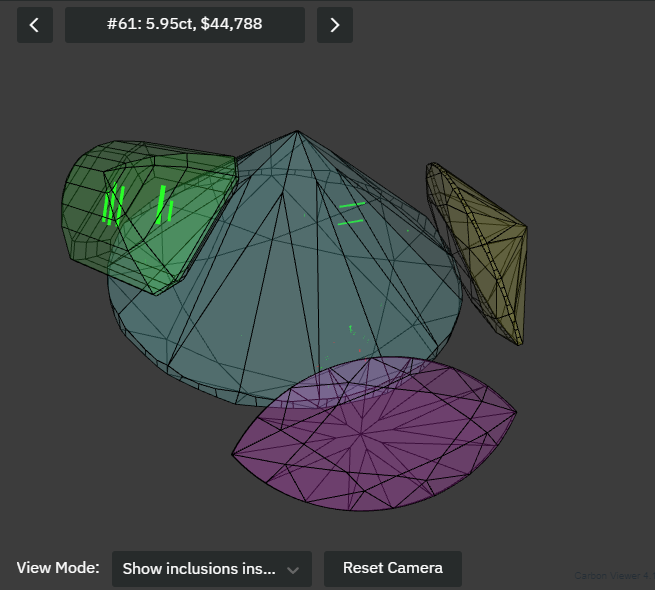

| Show inclusions inside | Shows:

Note If only some part of inclusion is inside a diamond it will also be displayed. Hides:

| |

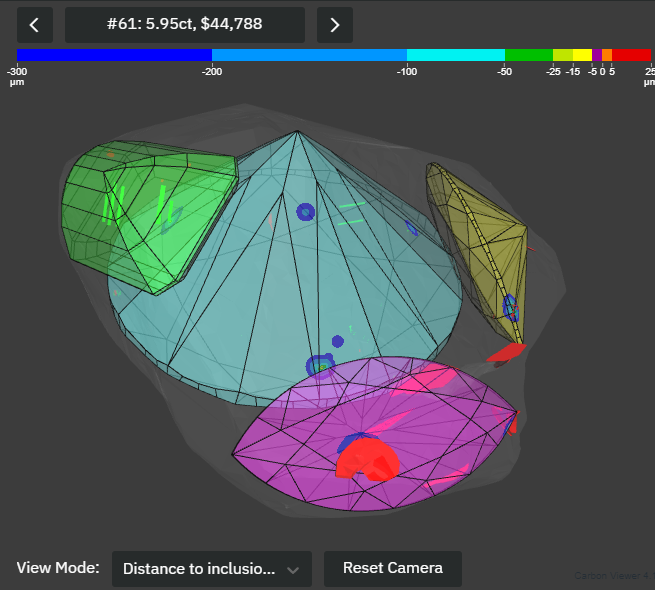

| Distance to inclusions | Shows:

| |

| Distance to rough | Shows:

Note "goes outside" situation is wrong ("red") and may be caused by manual changes of a model. | |

| Distance to diamonds | Shows:

Note "goes outside" situation is wrong ("red") and may be caused by manual changes of a model. | |

| Rough | Shows:

|

How to upload correct data to Cutwise projects

When uploading from HP Carbon, ViBox, and DiBox to Cutwise, it is important to have data related to the same rough (its scan, solutions, final polished stones) within the same Cutwise project. See current recommendations and examples of how to achieve that in the article:

Inclusions mode

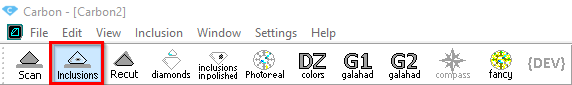

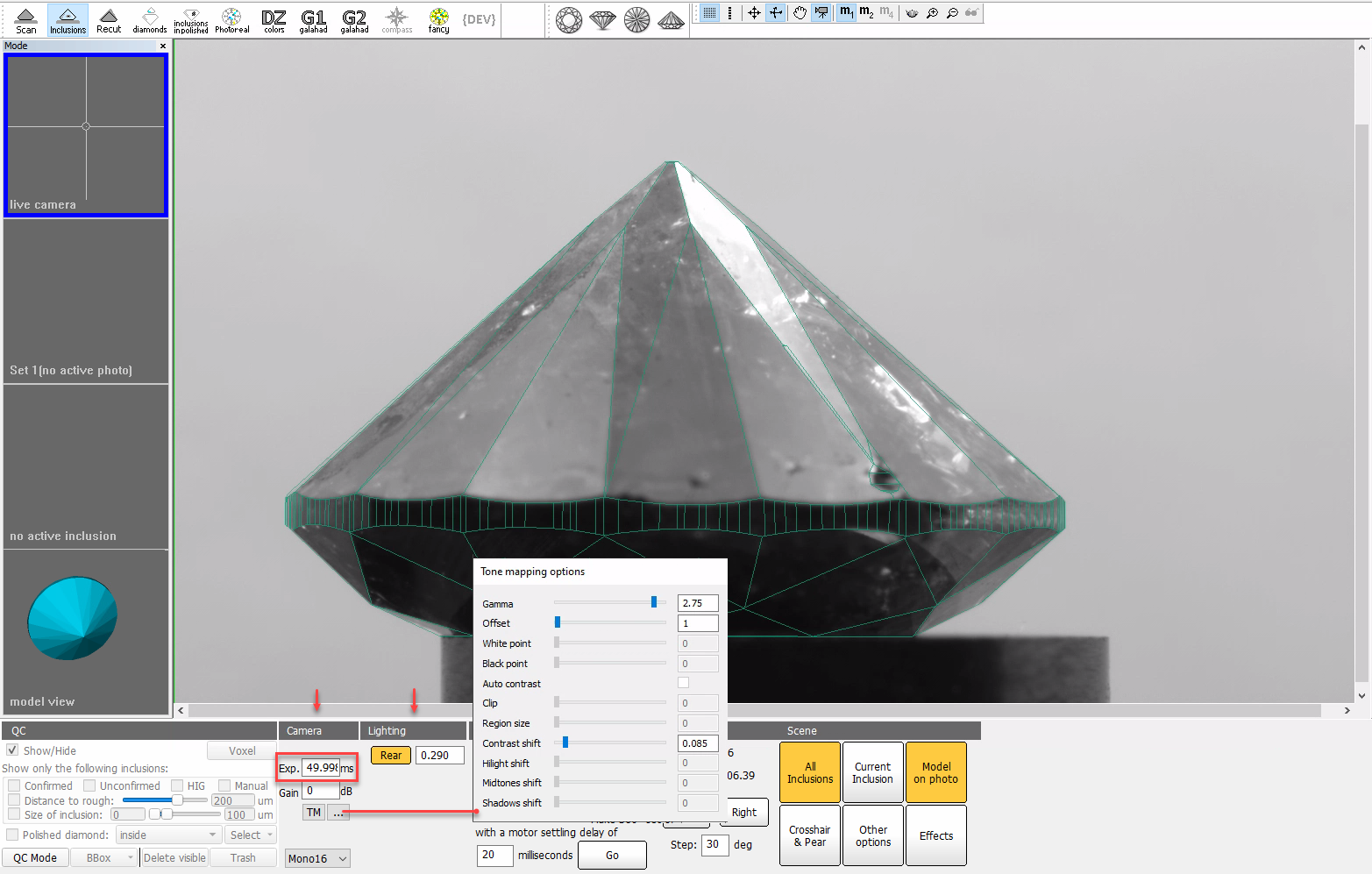

Now you can plot cavities manually on your model using the new Inclusions mode. To switch to the Inclusions mode, on the top panel, click Inclusions.

The following scenarios can be implemented in this mode:

- Plot cavities in live mode

- Plot cavities via photo sets

- Quickly prepare quality photo(s) of your rough

See details in the sections below.

Plot cavities in live mode

To plot cavities in live mode:

- Prerequisites: Shadow scanner is connected

- Scan your semipolished diamond, then go to Inclusions mode.

- In your scanner (hardware), change the lighting.

- In the Inclusions mode, "live camera" Mode, adjust the Camera (specifically, exposure Exp.) and Lighting settings to have the best view of your diamond.

- Rotate your diamond via mouse drag, and then above the "live camera" view of it, for your model, add cavities and adjust facets using Boundary Plane Tool.

- Save your project.

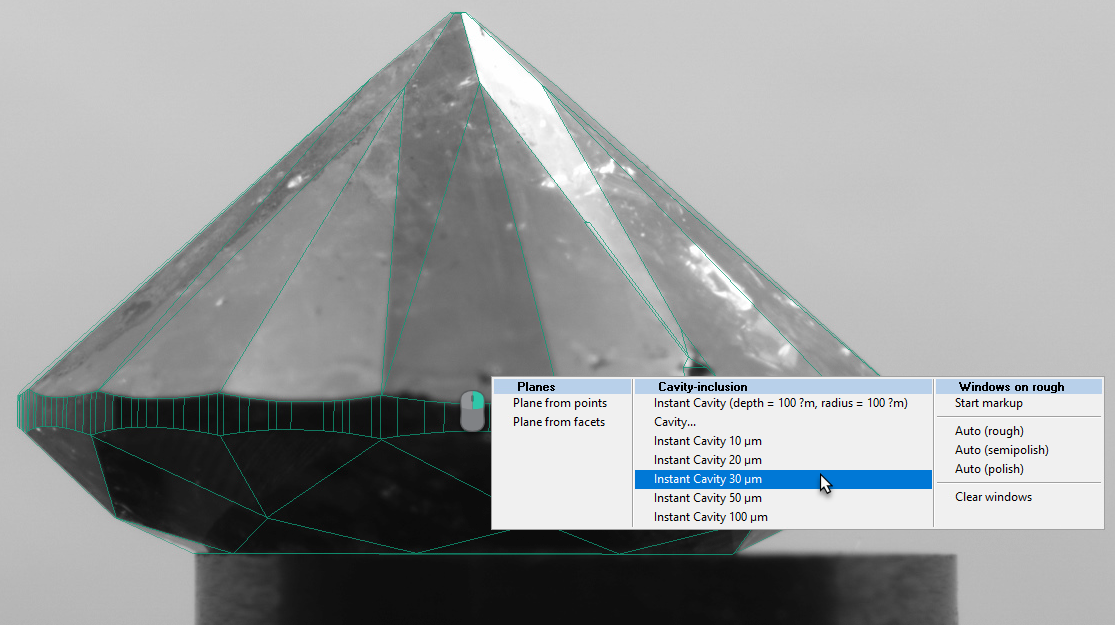

Plot cavities via photo sets

Note

In the following description, 2 operators are acting - this is optional, all the activities described may be performed by the same operator.

To plot cavities via photo sets:

- Operator 1:

- Prerequisites: Shadow scanner is connected on the first stage (not needed on the second)

- Scan your semipolished diamond, then go to Inclusions mode.

- In the Inclusions mode, "live camera" Mode, you adjust the Camera and Lighting settings to have the best view of your diamond.

- Make a new 360° photo set.

- Save your project along with the photo set and send them to Operator 2.

- Operator 2:

- In HP Carbon, open the project, go to Scan mode.

- On the right panel, use the Photos section to open the photo set.

- Go to Inclusions mode, use photo Mode.

- Rotate your model via mouse drag, and then above its "lifelike" view, for your model, add cavities and adjust facets using Boundary Plane Tool.

- Save your project.

Quickly prepare quality photo(s) of your rough

To quickly prepare quality photo(s) of your rough:

- Prerequisites: Shadow scanner is connected

- Go to Inclusions mode.

- In the Inclusions mode, "live camera" Mode, you adjust the Camera and Lighting settings to have the best view of your rough.

- Shoot any number of photos or photo sets.

- Save photo sets to disk.

- If necessary, use any tool to convert series of images into a video for a "motion" presentation of your rough.

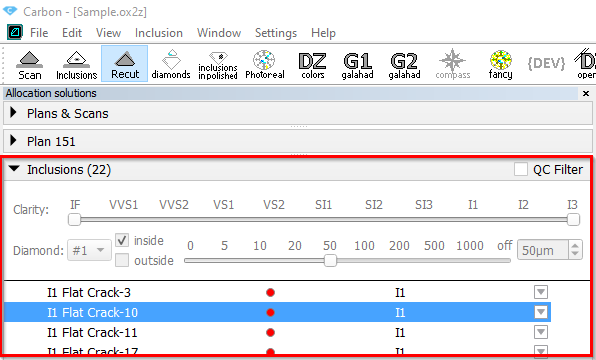

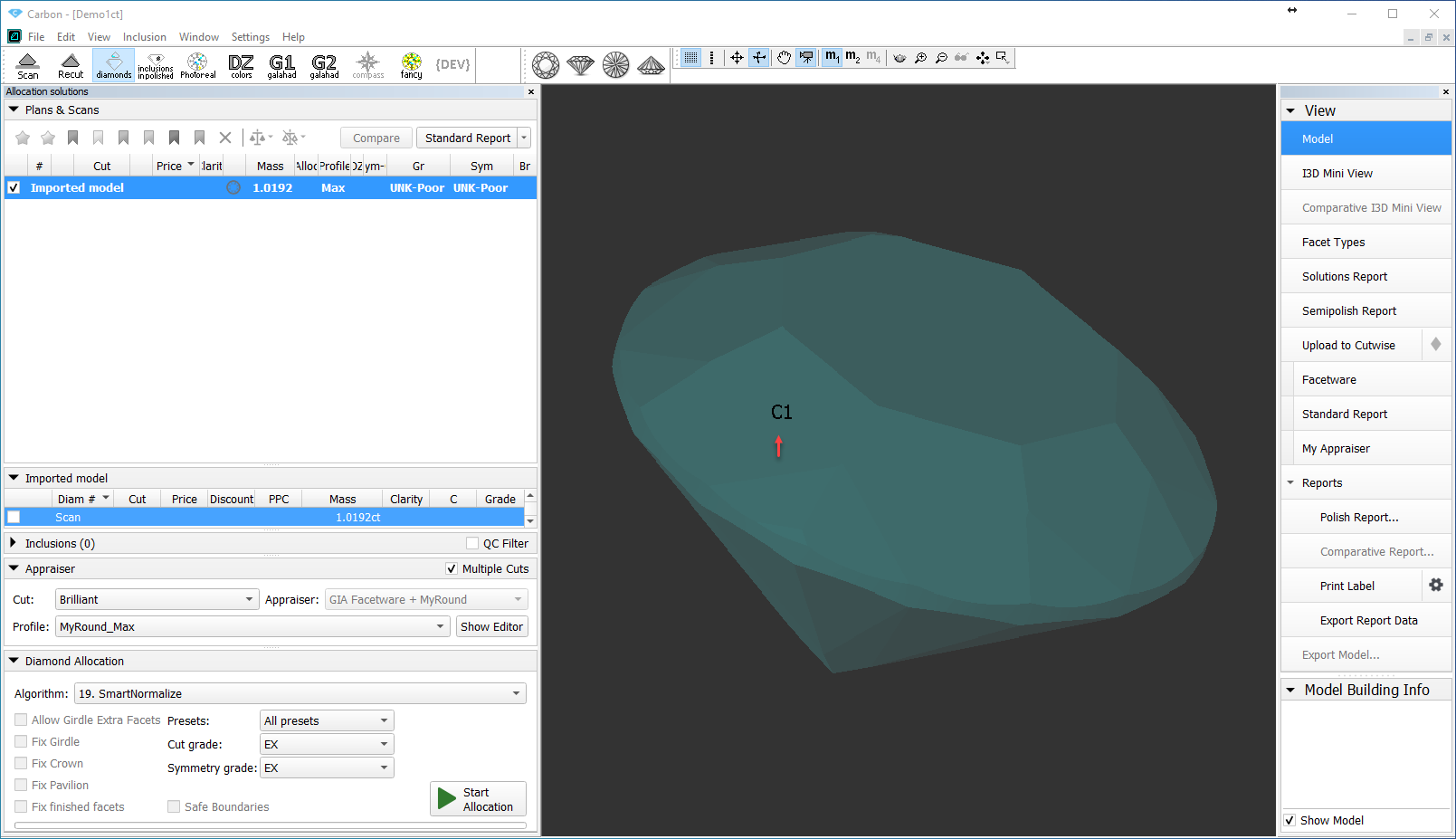

Handy change of clarity or status of inclusions from scene

There is option to change clarity or status of inclusions from scene by two clicks:

Example

There is known issue that after change of clarity or status there is no update in Inclusions list:

This will be fixed in next version.

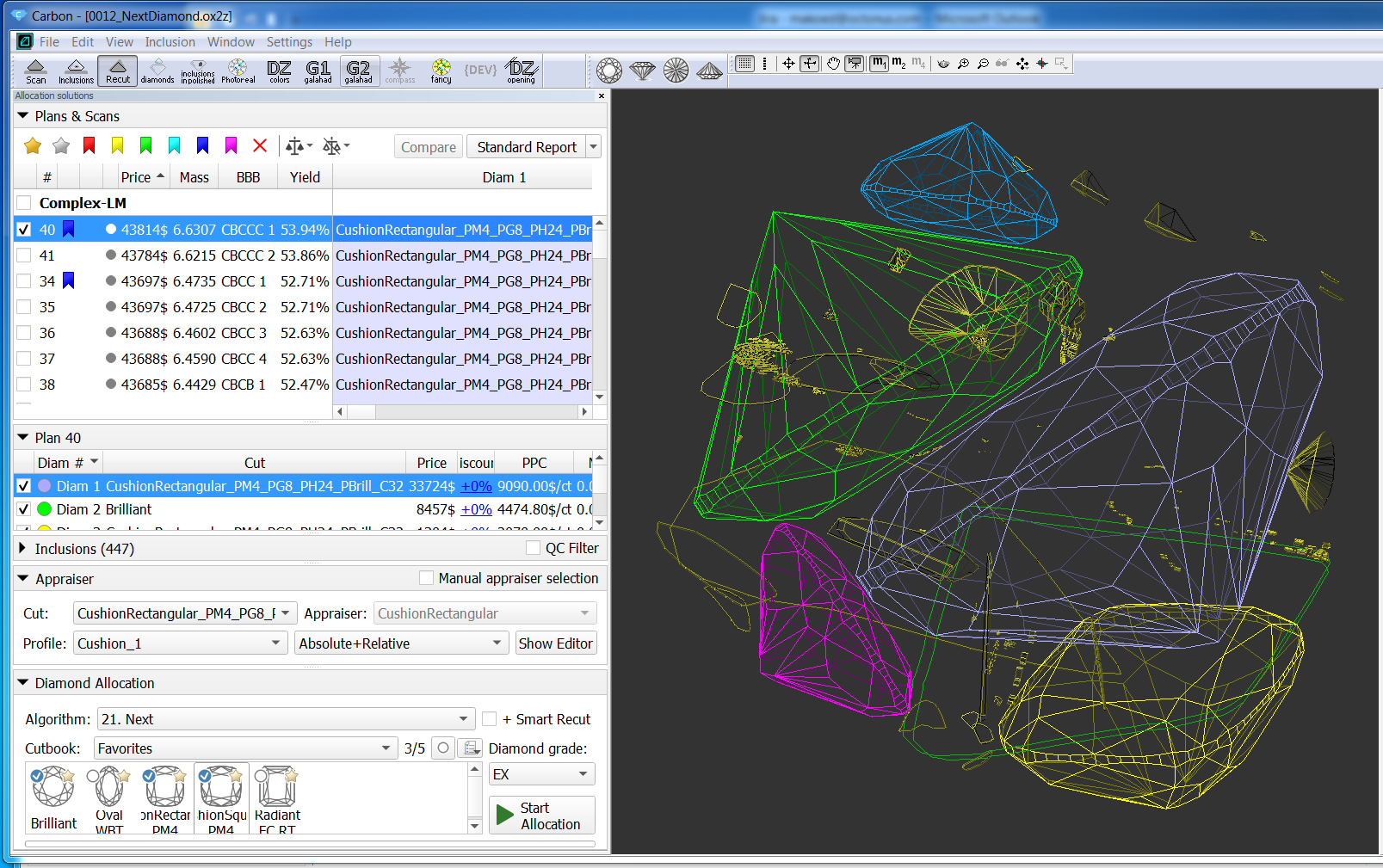

Algorithm "21. Next"

To add one more diamond to already created solution you can use algorithm "21. Next". The next diamond will be added in maximal possible free zone of rough volume which is not occupied by created before diamonds. A position of existing diamonds is not changed.

Important! Algorithm "21. Next" during work takes into account allocation forms of Cut that allows to find better solutions for in-house cuts. Note that algorithm Find Next Diamond in Helium Rough / Pacor Client doesn't work with many allocation forms so we recommend to use "21. Next" and HP Carbon to find next diamond.

Before run of algorithm please make sure that you select one or several solutions where you want to add one more diamond and cut types from Cutbook.

There is possible to create solutions composed of 2, 3, 4 and so so diamonds.

There is a sample of algorithm "21. Next" work:

0012_NextDiamond.ox2z

Sol. #40 contains 5 diamonds, it was allocated sequentially from sol. #24, 30, 34.

In-house cut workflow improvements

Compatibility of in-house cuts and linked appraisers between HP Carbon and Helium Rough/Pacor Client

Currently some allocation algorithms exists only in Helium Rough/Pacor Client but not in HP Carbon. Mainly there are semi-automatic or manual algorithms, that are available in Tools mode (like "Fixed Diamond Weight", "Change cut" and so on).

Therefore the same project is need to be open in both programs (HP Carbon and HR/PC) and compatibility of cuts and appraisers is required for work convenience.

Previously registered in HP Carbon Cuts and linked Appraisers are automatically loaded to Helium Rough since version 7.4 if Helium Rough is installed on the same computer.

Hybrid Appraisers (with Absolute and Relative parts) has limited compatibility:

- Helium Rough program version 7.4 doesn't have option to enable/disable Absolute and Relative parts.

- There is no convenient switch between profiles

Helium Rough will allocate with the same conditions of hybrid appraiser like they was during exit from HP Carbon. Under conditions we mean absolute, relative parts and profile .

Example of work:

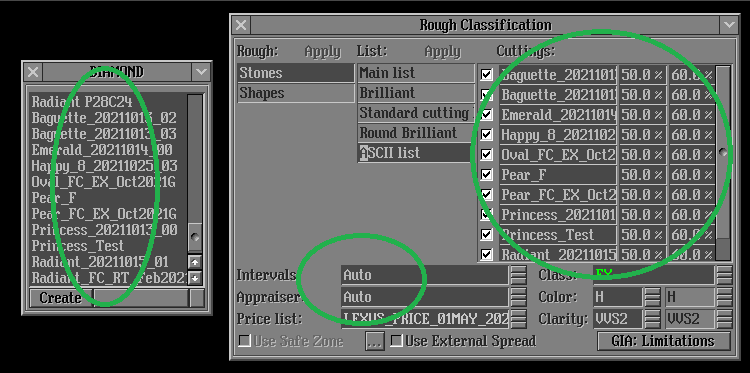

Suppose we have following list of in-house cuts in HP Carbon:

When we run Helium Rough then the same cuts will be available in panel Diamond.

To run allocation with in-house cuts it is required:

- To create new list in Rough Classification panel and add necessary in-house cuts there.

- Select Intervals/Appraiser Auto.

Auto Appraiser allows to run allocation with several cuts and their linked different appraisers.

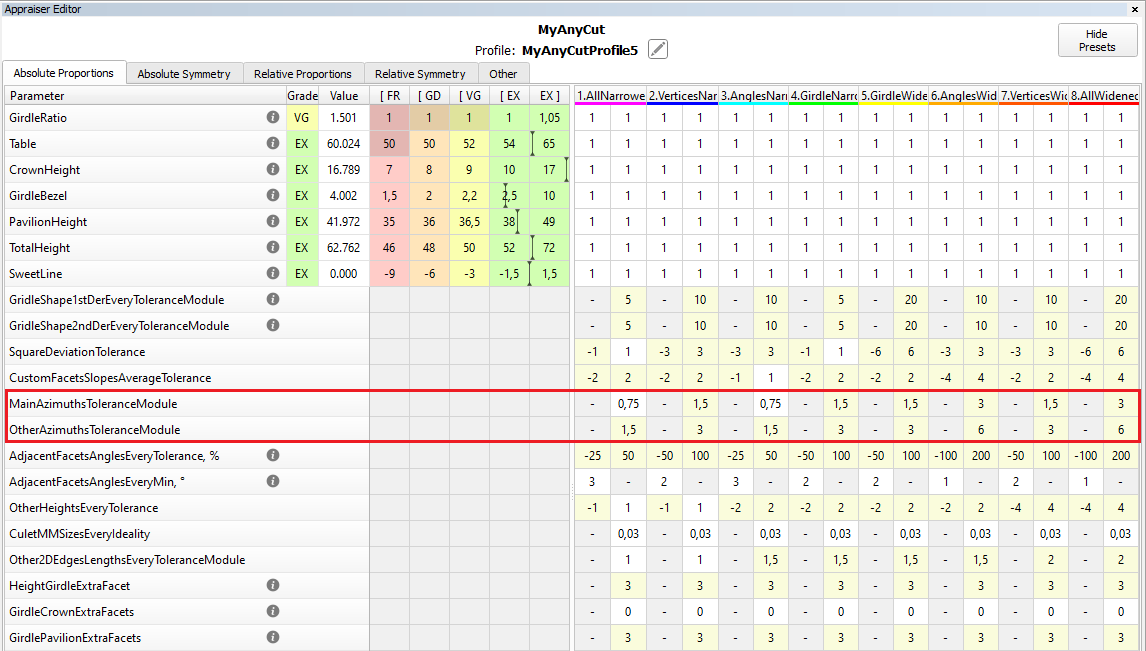

Usability upgrade of "MyAnyCut" appraiser presets for in-house cuts

To simplify navigation, the parameters in MyAnyCut presets are sorted into groups with the addition of prefixes in the names: "Girdle_", "Angles_", "Distances_", "ExtraFacets_"

Integrated documentation is connected for all parameters of the "Girdle_" group.

If you need to reduce the Area Loss of the SmartRecut solution, then decrease the Girdle_PointsAxialSymmetryIdeality via presets and restart the optimization.

Some exceptions are described in the integrated documentation Girdle_PointsAxialSymmetryIdeality or under in program.

Holder replacement in a scanner

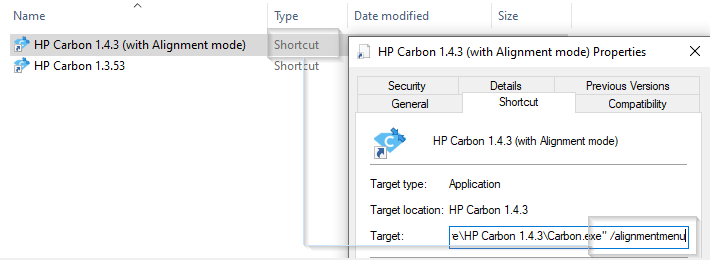

Holder deterioration requires it's replacement sometimes to get correct results of scanning. Now this procedure is accessible for users with special "Alignment" license bought from supplier.

You can order brand-new holders from scanner supplier too.

A procedure of holder change is described in Manual about holder change.

To use this functionality all the conditions should be met:

- You should use the system with HASP key with "Alignment" option,

- The system should be launched by the shortcut of Carbon.exe with the "/alignmentmenu" flag.

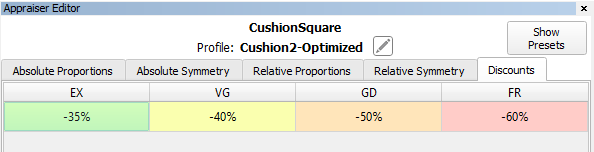

Cut Quality groups discounts

There are price discount for cut quality groups defined in appraiser. Initial discount that we provide "from a box" may not correspond actual market demand and specific customer needs.

There is a new Discount tab to edit discounts for Cut Quality groups (EX, VG, GD etc.) in Appraiser Editor panel:

Get symmetrical solutions in spite of mistakes in facet types

| The change caused by Request | LR-107 - Getting issue details... STATUS |

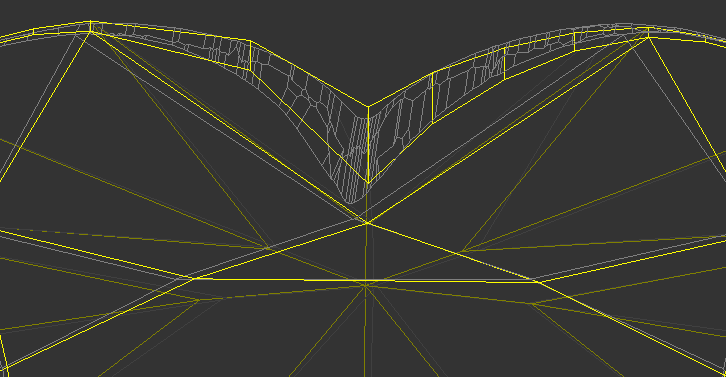

To increase model symmetry and remove excess facets, you can use the Smart Normalize algorithm. Previously, if the model that you were going to normalize had mistakes in its facet types, Smart Normalize could provide non-symmetrical solutions. Now the algorithm is improved: it tries to fix mistakes in facet types and then provides excellent symmetry.

Hint This is especially useful when mistakes are not obvious to an operator.

Technical details:

- The algorithm tries to fix facet type mistakes using information about groups of symmetrical facets and which type dominates in a group. If the situation is clear enough, mistakes in facet types are fixed automatically and the algorithm finds the solution with the correct number of symmetry axes. If the case is too complex, the algorithm uses initial facet types without changes.

- Fixing does not change the initial model facet types but does change the resulting model - it will have different (fixed) facet types.

Example:

| Easy to see with the eyes | Not obvious to an operator | |

|---|---|---|

| Initial model | ||

| Normalized model |

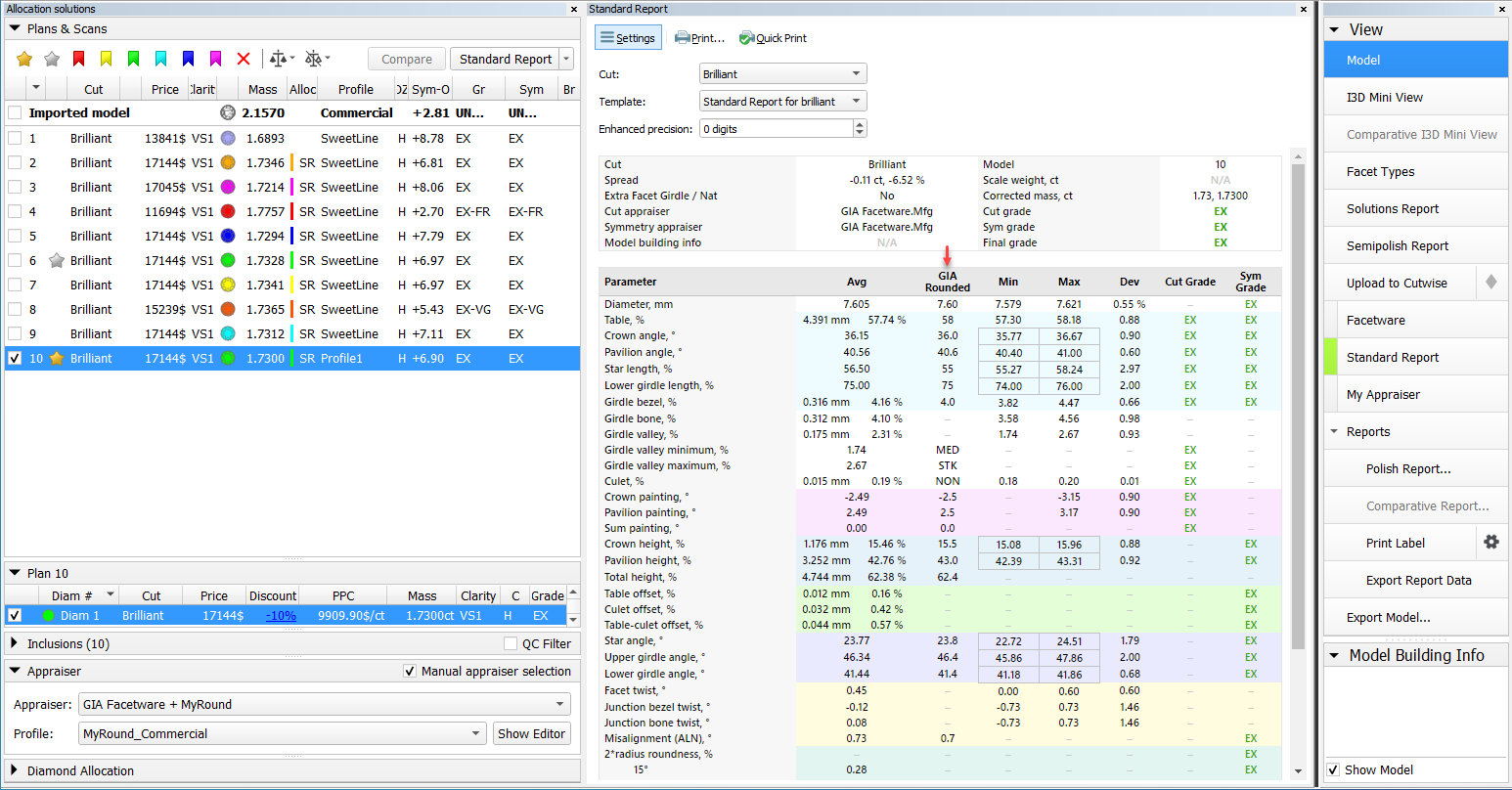

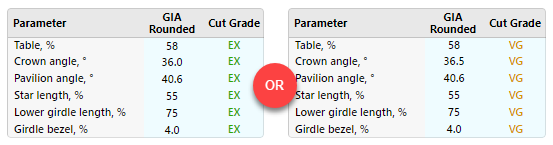

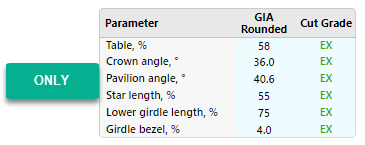

Get plans for Brilliant cut that are safe from perspective of GIA cut grade

In HP Carbon, plans for Brilliant cut are allocated with the "GIA Facetware + My Round" appraiser. GIA Facetware rounds the parameters' values.

In some cases, this rounding may cause a problem: when you finish cutting in precise accordance with the plan and the result is scanned, different scanners (for example, yours and GIA lab) may slightly deviate the scanned model. So if our plan was too close to rounding boundaries, the resulting parameter value after rounding may go outside the EX boundaries to VG, etc. This can cause your EX stone from your scanner perspective will unexpectedly become VG from the GIA lab perspective.

To eliminate this risk, for the Smart Recut algorithm, the new Safe Boundaries mode is added. It is intended to be used when working with Brilliant cut. The mode sets safe distances to a possible GIA rounding. The values are:

| GRID Parameter | Margin | Units |

|---|---|---|

| Table | 0,008 | mm |

| Crown angle | 0,10 | deg |

| Pavilion angle | 0,06 | deg |

| Star length | 1,5 | % |

| Lower girdle length | 1,5 | % |

| Girdle bezel | 0,1 | % |

| A usual SR produced 36.24, it was rounded by GIA to 36.0 which gave ЕХ. When you scanned after cutting, your scanner gave 36.24, but another one (GIA lab?) produced a model with 36.26. This will be rounded to 36.5 and will give VG. Result: lost money. | And the Safe Boundaries mode will step out from the disputed border 36.25 by 0.1 and will produce plan 36.14 instead of 36.24. This may lead to a little mass decrease (probably even not affecting the price). But you are guaranteed to get an EX GIA grade at any scanner. |

| Other GIA Cut parameters | Margin | Units |

|---|---|---|

| Girdle valley Min | 0,1 | % |

| Girdle valley Max | 0,1 | % |

| Culet | 0,1 | % |

| Crown painting | 0,2 | deg |

| Pav painting | 0,2 | deg |

| Sum painting | 0,2 | deg |

At the moment, these values cannot be changed - in the future, it is planned to provide a user interface for viewing/editing.

The mode is turned on by the Safe Boundaries checkbox.

The mode can be used when running the Smart Recut allocation from Recut solution. However, if you already have a Smart Recut solution previously obtained without using the Safe Boundaries option, it is more effective to run Smart Recut allocation with Safe Boundaries from this previous Smart Recut.

The Table parameter can obtain a value close to the GIA rounding boundary (for example, 58.49%). This means that regardless of rounding up or down (58% or 59%) the required GIA Cut Grade will be produced with the other 5 GRID parameters set.

Fancy Color workflow improvements

The below functionality is available only with product/license "FancyColor" bought from supplier and activated in your HASP key.

OctoNus library with cuts optimized for color performance

There is a library of specially designed and optimized for enhanced fancy color performance Goodwin cuts:

Cushion_FC_RT1_1_EX_Oct2021G, Cushion_FC_RT1_2_EX_Oct2021G, Oval_FC_EX_Oct2021G, Pear_FC_EX_Oct2021G, Radiant_FC_EX_Sep2021G, Radiant_FC_RT_Oct2021G

Every cut in the library is packed with a protected set of allocation forms and preliminary tuned appraiser. Effective set of optimized allocation forms is especially important for fancy color diamond allocation.

Separate smart recut settings for fancy color cuts allocation

Allocation of the Fancy Color diamonds has some additional important goals: better color intensity and distribution. These goals require the SmartRecut engine to be more fine and accurate when changing the initially color-optimized diamond form in order to avoid degrade of color performance. To settle this difference between color optimized and colorless allocation we need SmartRecut to operate on different set of settings known as "smart recut presets". The HP Carbon 1.4 has a new special set of smart recut presets for AnyCut Fancy Color diamond allocation which can be modified independently from the usual AnyCut presets which are used normally for colorless allocation. At the stage of the registration of new In-house cut operator can tell the program that the cut will be used for fancy color allocation, by ticking the "Fancy Color" option. So the SmartRecut will use the proper set of SmartRecut presets when dealing with "Fancy Color" ticked In-House cuts. The following illustration demonstrates this new option.

NB Please notice that the Cuts from OctoNus Fancy Color optimized cuts Library is already marked and will work with AnyCut Fancy Color SmartRecut presetes.

TIP:

For your convenience and easy self-identification of your own optimized Fancy Color we recommend to add "_FC" symbols in the name of the In-House cuts, like Oval_FC_OtherProperties..

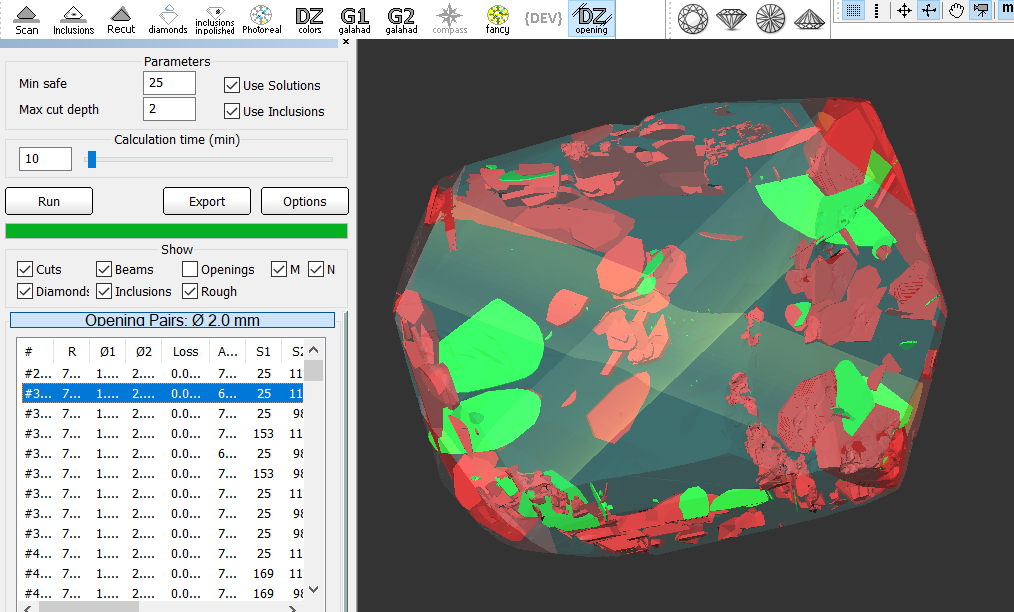

Spectrum opening calculation

Since HP Carbon 1.4 you can use a mode for calculation pairs of parallel windows or "openings" required for absorption spectrum measurement.

There is "opening" button in the top toolbar:

The function of the Openings mode is similar to former "Oxygen DZ" software.

Reports improvements

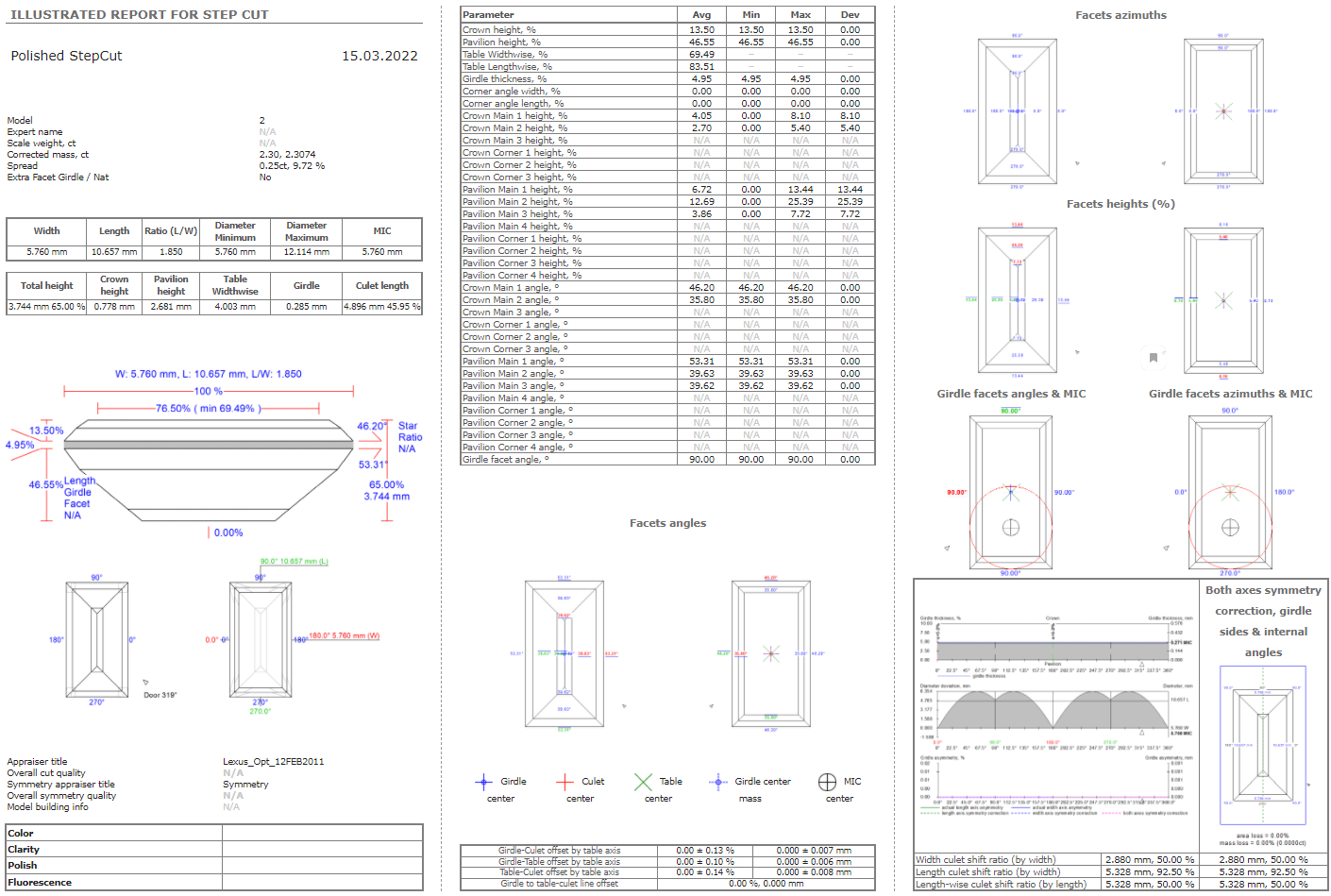

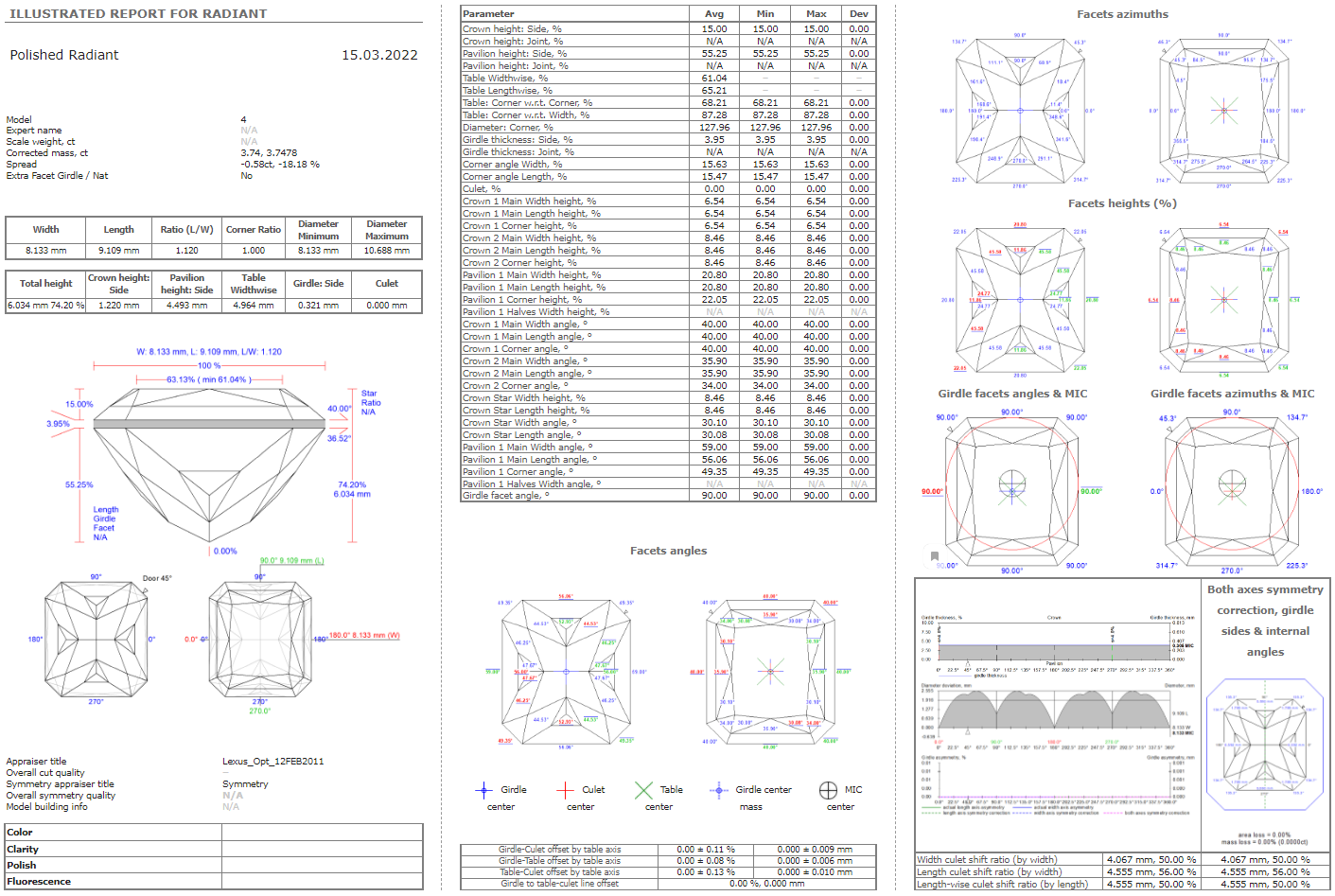

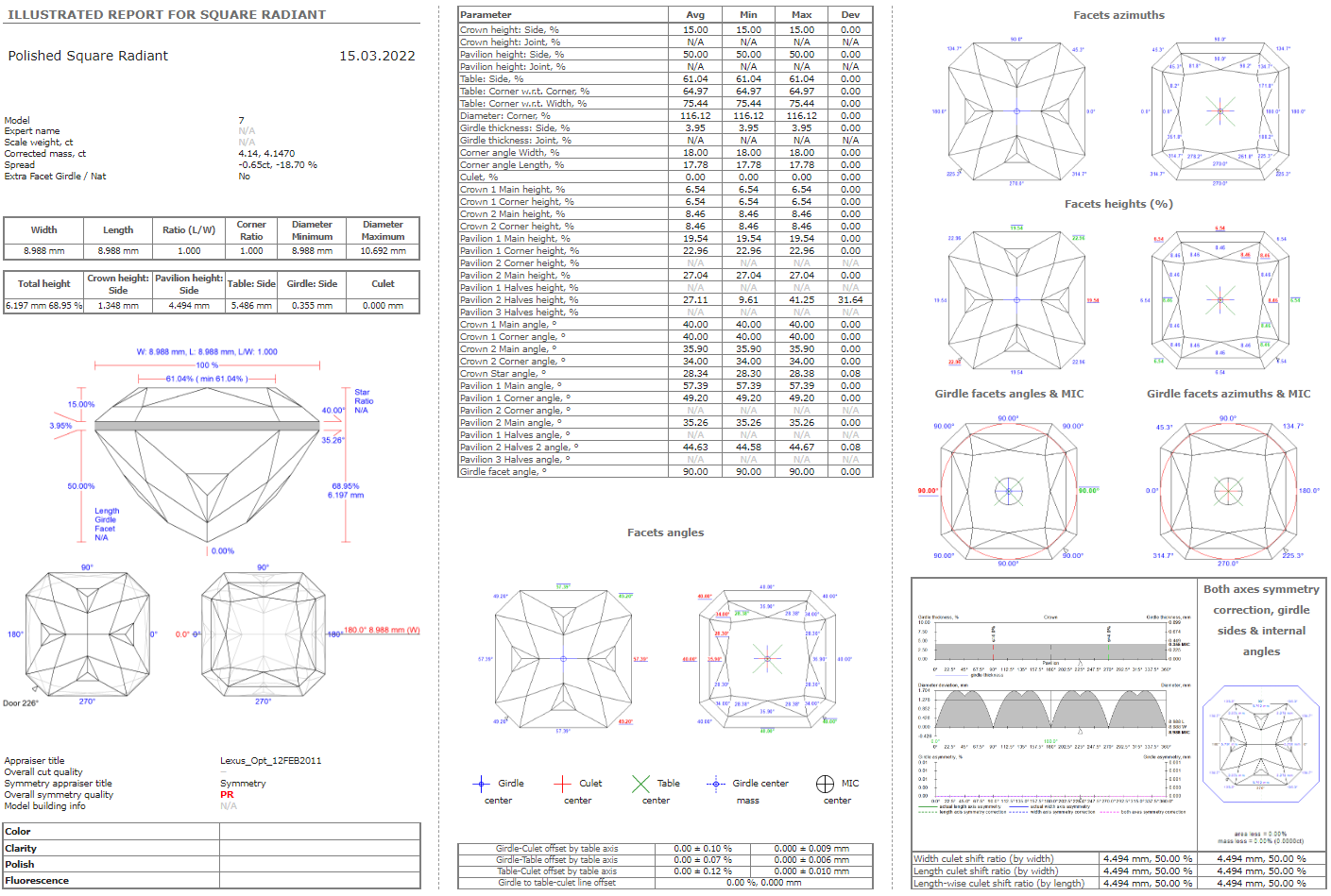

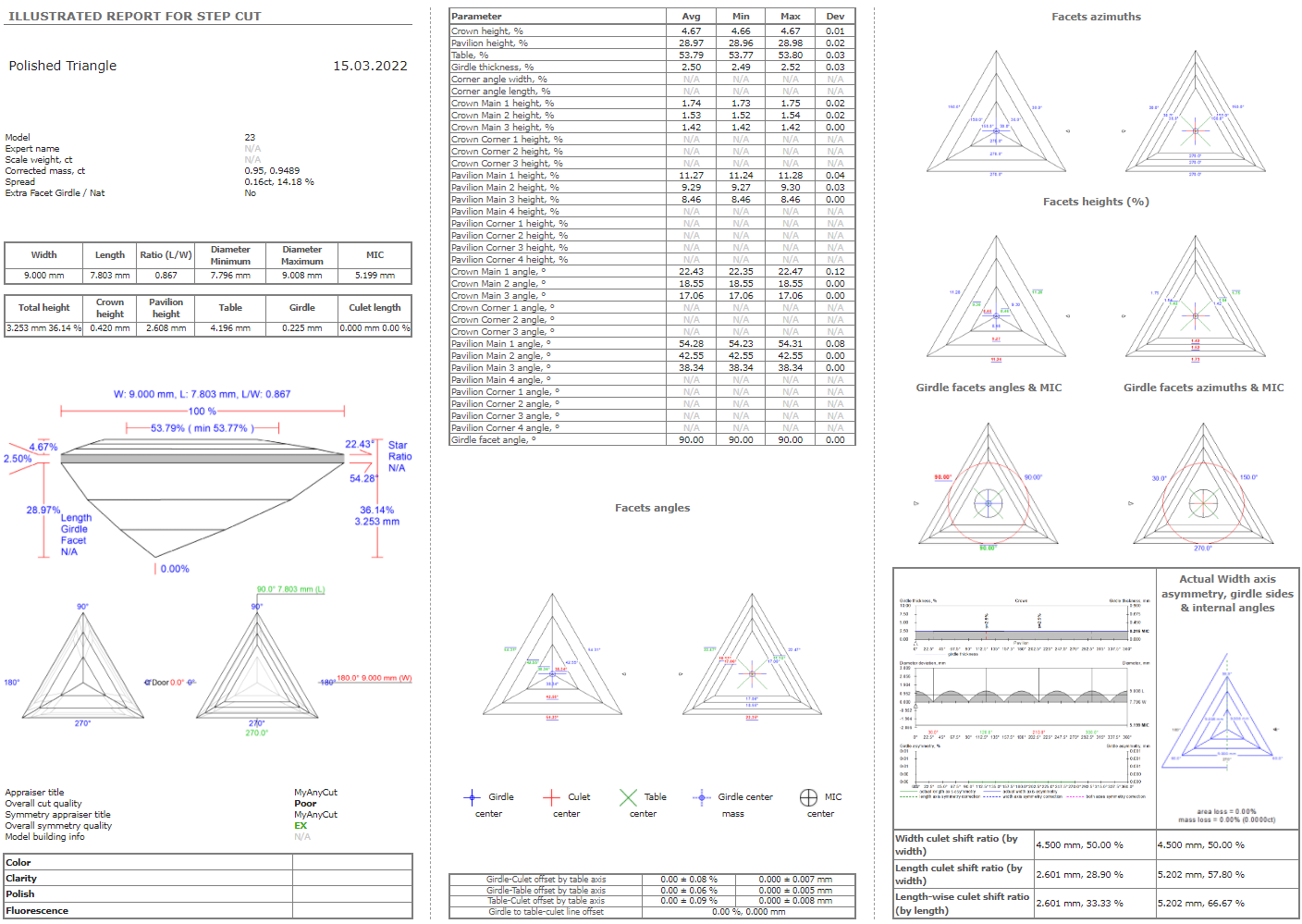

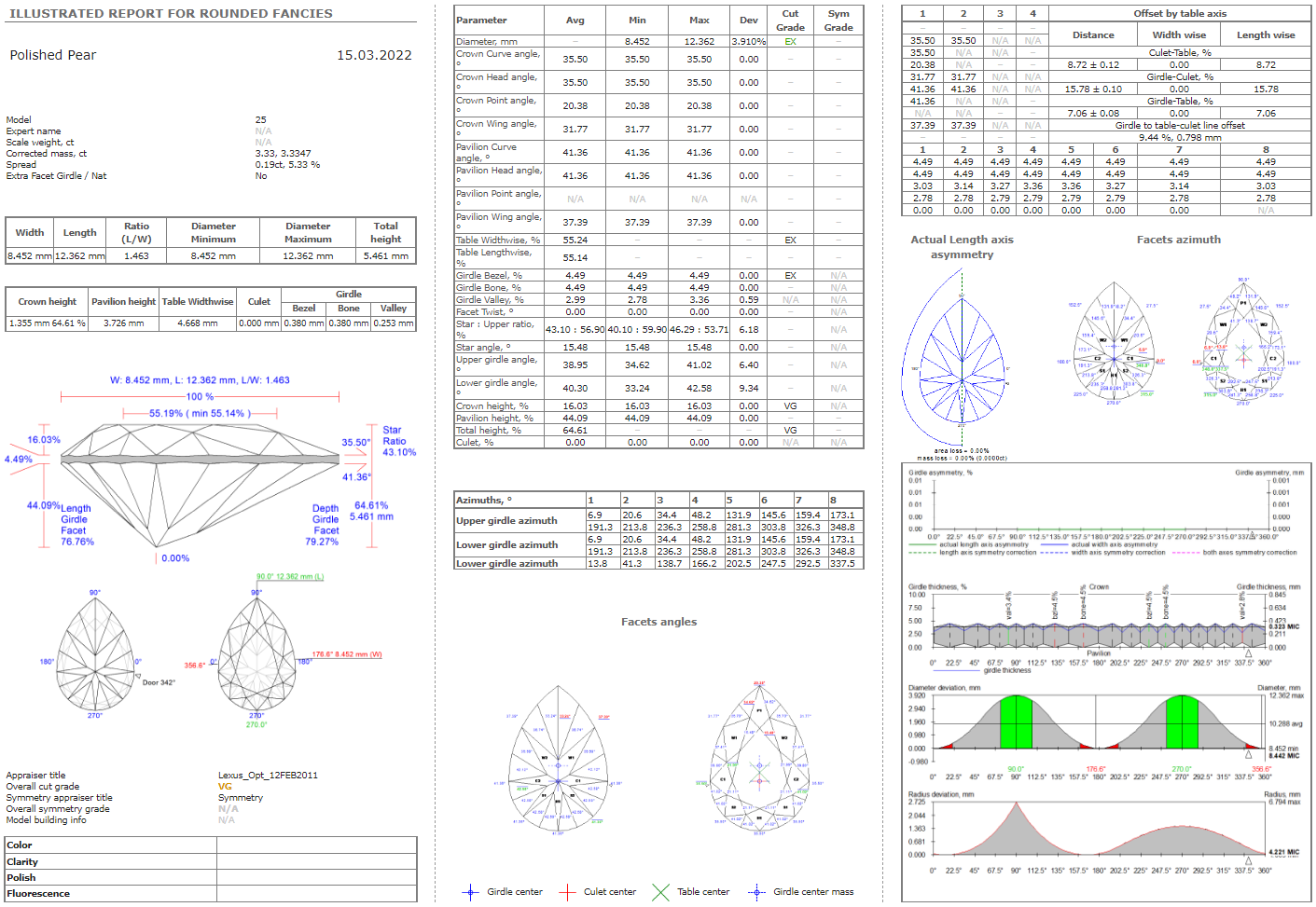

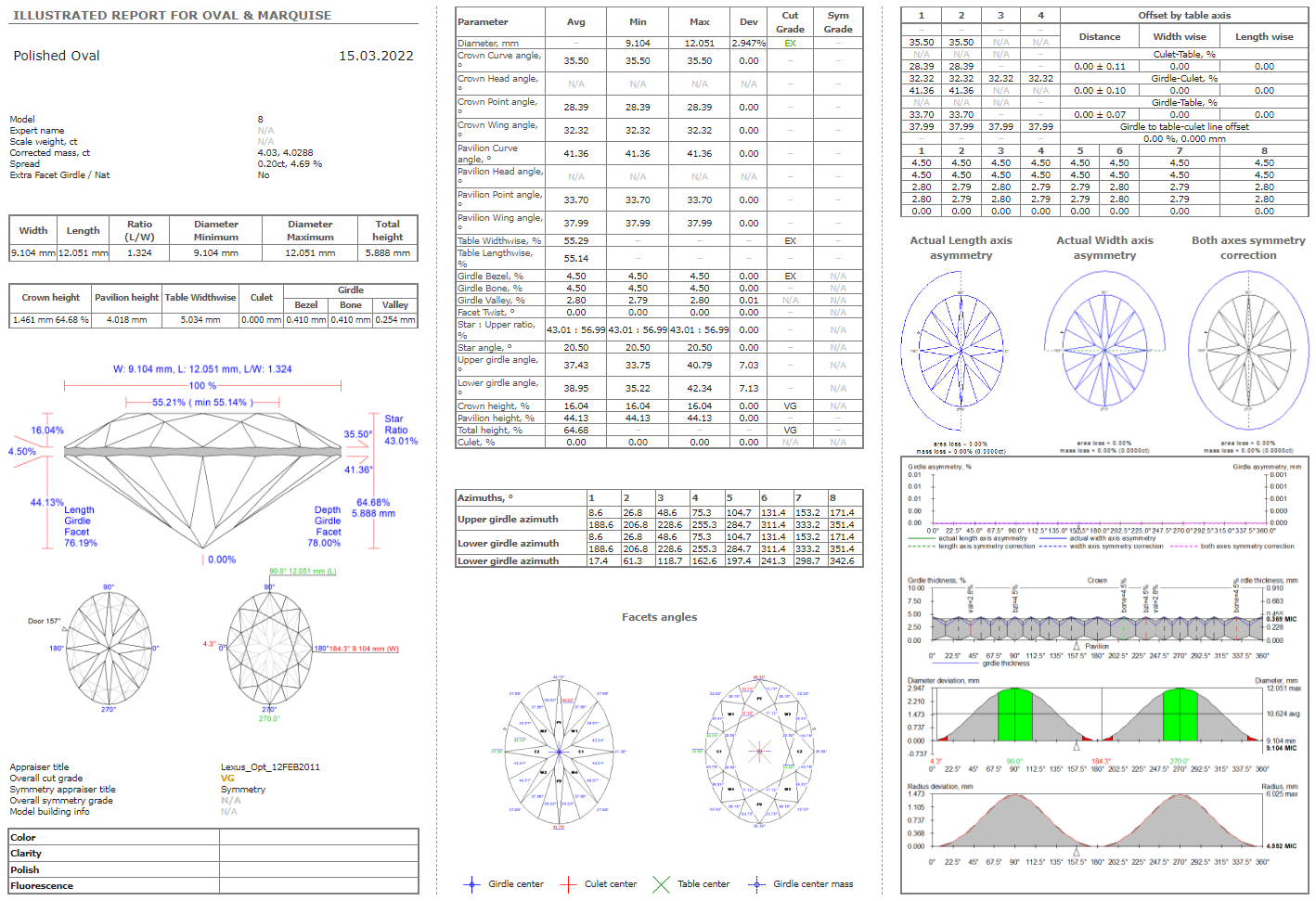

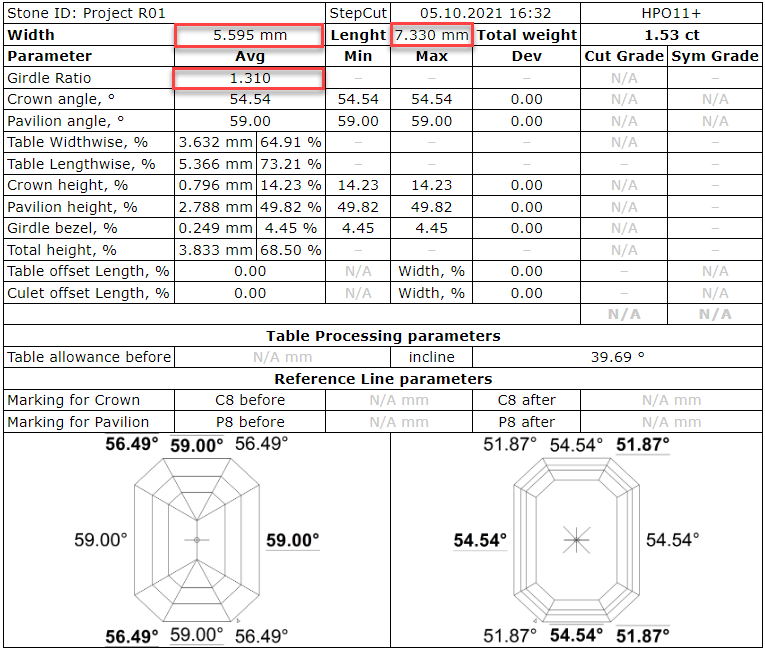

Illustrated HTML Report templates for many other cuts are available (besides RBC)

The convenient single-page reports in HTML format have been made for most types of cuts (as was previously done for RBC), so that the operator, without the need to use MS Word, could open the main parameters of the model on the screen on one page and transfer them to the clients/auditor/manager:

- Polished HTML Illustrated Report Step Cut;

- Polished HTML Illustrated Report Radiant;

- Polished HTML Illustrated Report Square Radiant;

- Polished HTML Illustrated Report Triangle;

- Polished HTML Illustrated Report Rounded Fancies;

- Polished HTML Illustrated Report Oval-Marquise.

These reports are located in "Polish Report..." for a specific type of cuts, for an example:

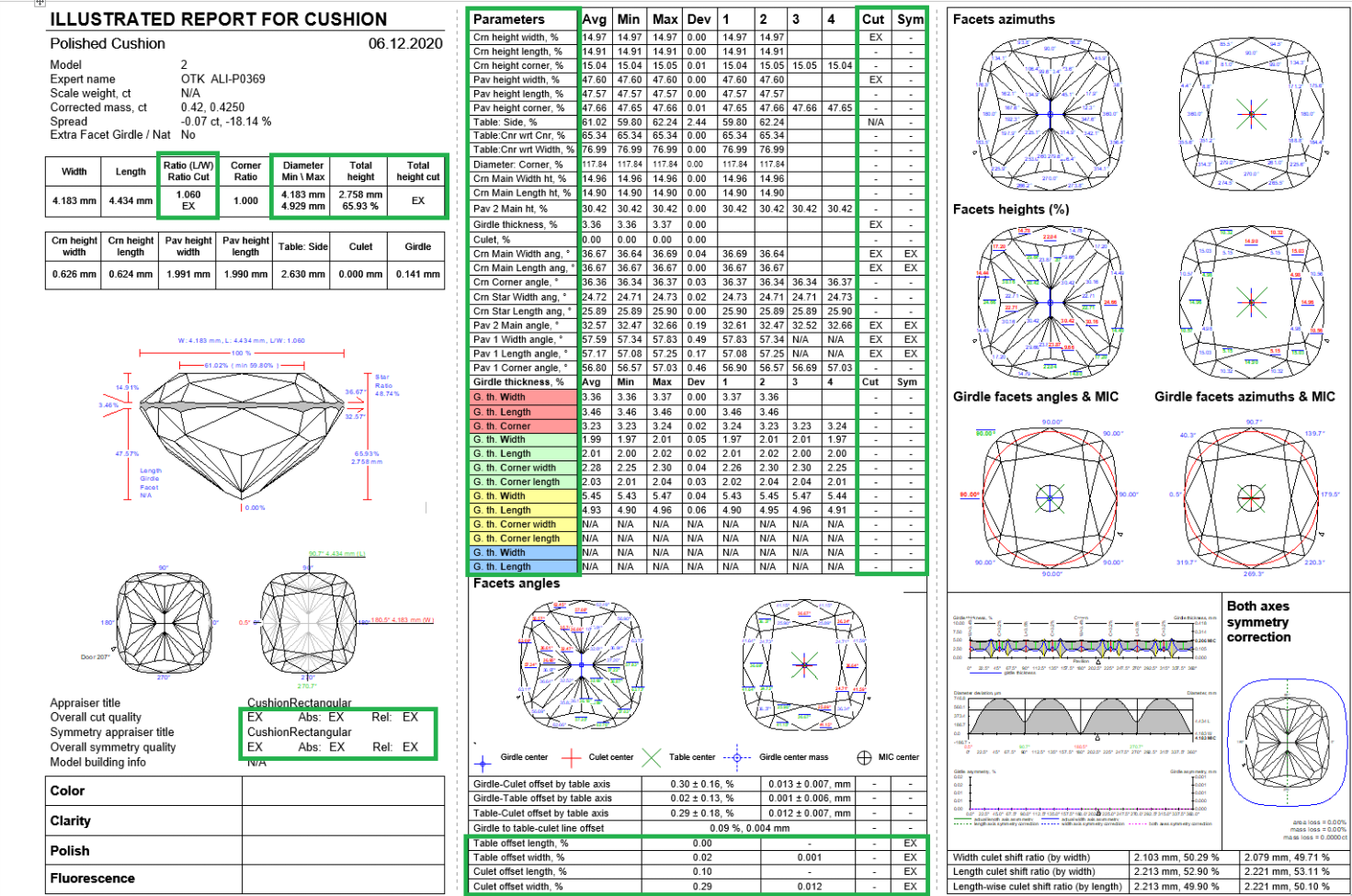

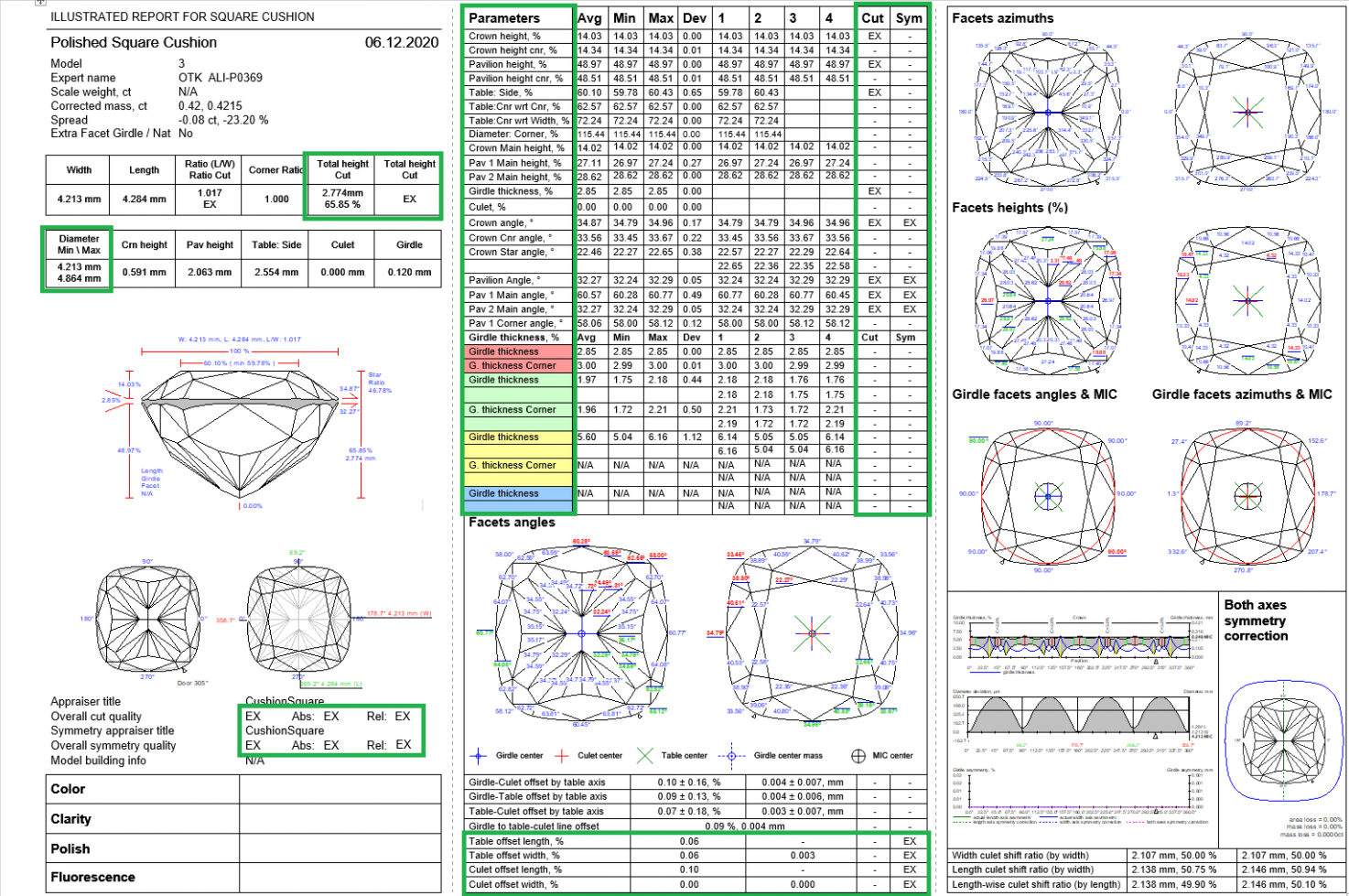

Examples of reports:

1) Illustrated HTML Report Step Cut

2) Illustrated HTML Report Radiant

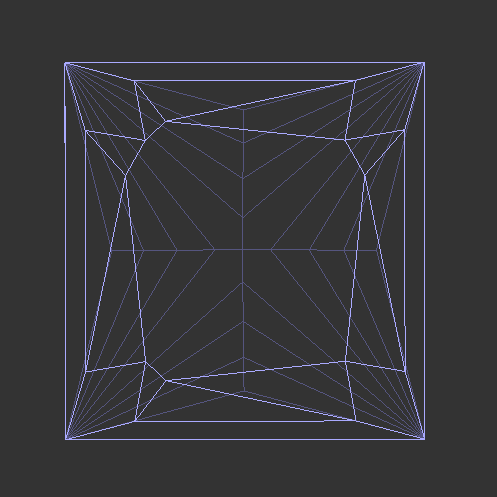

3) Illustrated HTML Report Square Radiant

4) Illustrated HTML Report Triangle

5) Illustrated HTML Report Rounded Fancies

6) Illustrated HTML Report Oval&Marquise

View grades for Cushion cuts in reports

For the Rectangular and Square Cushion cuts the grades were added to the following reports:

- Standard report

- HTML Illustrative report

- RTF Illustrative report

- Label report

Some minor layout changes were caused by this change (shorten parameter names and display positions.

| Rectangular Cushion | Square Cushion |

|---|---|

View with and length for lengthened cuts

Information about the width, length, and girdle ratio is added to:

- Label and Semipolish reports for all cuts.

- Standard reports for all cuts except Brilliant.

Control absolute value azimuths for in-house cuts

In previous versions, for in-house cuts the algorithm 19. SmartRecut (Brilliant, Oval, AnyCut) controlled only the azimuths symmetry of the facets. But a change in the absolute value of azimuths could lead to a big loss of the solutions performance.

Therefore two parameters have been added to control the tolerance of azimuths from the initial values. More "narrow" MainAzimuthsToleranceModule is tuned for only Main facets. Less "narrow" OtherAzimuthsToleranceModule is tuned for other facets.

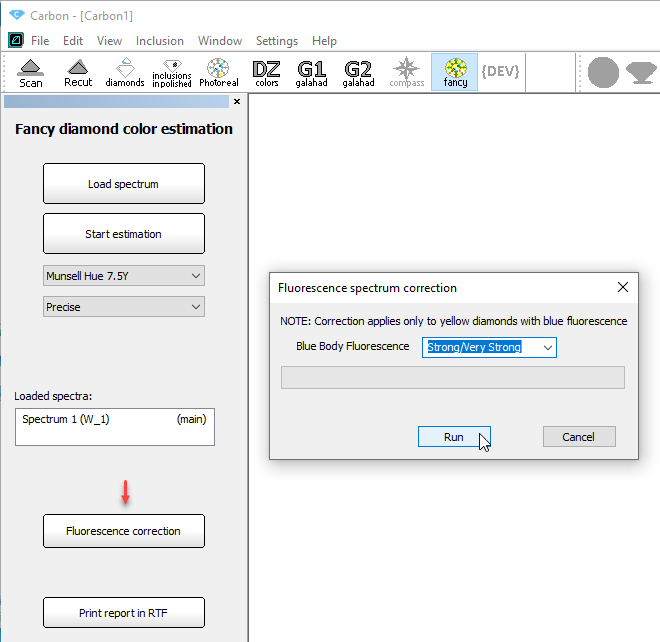

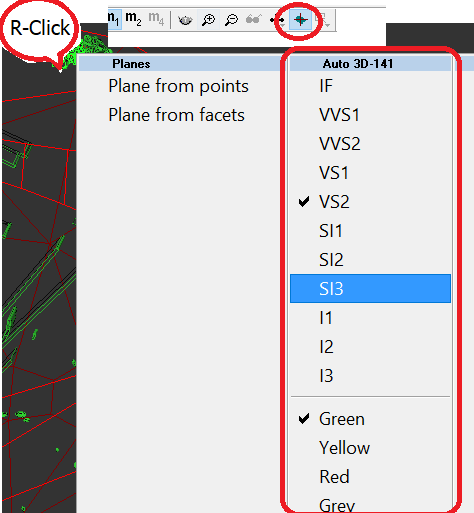

Get corrected color estimation for diamonds with fluorescence

For the stones with the fluorescence, for the Fancy diamond color estimation, you are now able to get the estimation corrected in accordance with the fluorescence effect level.

Correction can only be applied to the yellow diamonds with the blue fluorescence.

- Click Fancy.

- Click Load Spectrum, import your absorption spectrum from a file.

- Click Fluorescence correction. The Fluorescence spectrum correction dialog is displayed.

- In the dialog, from the Blue Body Fluorescence, select the level of fluorescence, then click Run.

The calculation starts, as soon as it finishes, to the Loaded spectra list, the corrected spectrum is added.

Galahad mode - Generate Faceting Stage with facets of united type

Since version 1.4.9 during generation of Faceting Stage in G1 (Galahad) mode operator can select all facets of one united type without separation to subtypes. For example, operator can select all facets of Crown Main or Pavilion Main facets simultaneously .

Thera are types added to list of facet types which combine subtypes and numbers. For example, for Oval Cut type Crown Main has 3 subtypes: Wing, Point, Curve. Operator can select either one of subtypes or common typу Crown Main:

Checking of Facet Types presence is added to Generate Next Stage panel of G1 (Galahad) mode:

Fixed problems and improvements

The following fixes for the known problems and improvements are implemented:

Now you can view the first facet of the stone right in the Scene (marker is added).

Simple way to change inclusion clarity - now it is possible to change clarity from context menu in the scene.

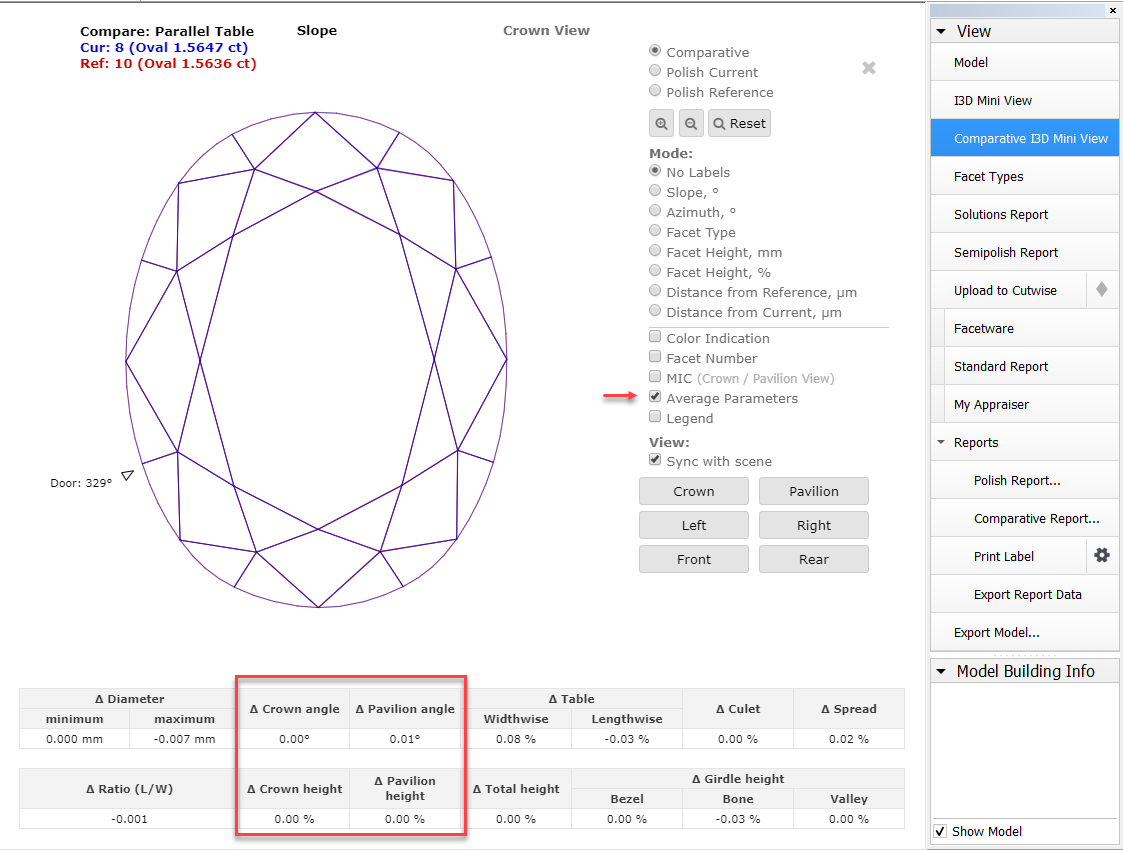

In Comparative I3D Mini View, for Average Parameters, some deltas were calculated incorrectly - now this is fixed.

In Facet Types, the way of displaying non-convex facets is fixed.

A perfect square cut has equal "Table along Width" and "Table along Length". Previously, only the "Table Widthwise" ("Table along Width") value was controlled in the appraiser "SquareCushion" by Absolute / Relative Proportions Table parameters. "Table Symmetry" parameter has been added to appraiser "SquareCushion" to control "Table along Length" value.

Algorithm Smart Normalize had different problems with Heart grooves. Algorithm Smart Normalize enhanced for Heart Cuts.

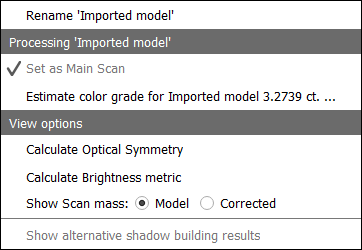

- The DZ color estimation in some cases froze the system because the rough scans were mistakenly treated as semipolished. Now:

- the scans have the Processing Stage parameter (Rough - Saw - Bruted - Semipolished - Polished) and DZ color estimation never starts for Rough - Saw - Bruted.

- the mechanism of automatic detection of the Processing Stage is improved

...which solves the "freeze" problem for most cases. In rare cases when Processing Stage is defined incorrectly, it can be changed manually (context menu of the scan > Change Processing Stage).

For projects with multi-diamond solutions, in the context menu of a scan, some items (for example, Processing Stage) were missing - now this is fixed.

Contrast of Inclusion (Faint, Slight, Medium, Dark, Very Dark) for visualization can be now specified in HP Carbon to have correct visualizations of Inclusions in photoreal in Carbon Viewer.

Improvement of refinement algorithm for building of models in HP Crown Reflect scanner. This improve the accuracy for some semi-RBC models.

In I3D Mini View Report now slopes of girdle facets are displayed in the range [0, 180] degrees. Before the range was [0, 90] degrees.

Slopes of other facet types are still displayed in the range [0, 90] degrees.

Lexus private details

The information in this section is for sharing with Lexus only.

Since 1.3.56 - changes in public features

Please, pay attention to the changes in Public Features that took place since the internal release 1.3.53:

New sections:

Executive summary for clients explaining USP of version and advantages of Goodwin usage during planning of in-house cuts.

Algorithm 21. Next is added

Compatibility of in-house cuts and linked appraisers between HP Carbon and Helium Rough/Pacor Client

Holder replacement in a scanner

Fancy Color workflow improvements

OctoNus library with cuts optimized for color performance

Separate smart recut settings for fancy color cuts allocation

Spectrum opening calculation

Control absolute value azimuths for in-house cuts

Changes in the existing sections:

Control angles for in-house cuts (Goodwin) - some accents are added in text sense, changes of graphics, sample for Fancy Oval and screenshots are added.

New among "Fixed Problems and Improvements":

- Simple change of active inclusion clarity - now it is possible to change clarity from context menu in the scene.

- Algorithm Smart Normalize had different problems with Heart grooves. Algorithm Smart Normalize enhanced for Heart Cuts.

- "Table Symmetry" parameter has been added to appraiser "SquareCushion" to control "Table along Length" value.

- Contrast of Inclusion (Faint, Slight, Medium, Dark, Very Dark) for visualization can be now specified in HP Carbon to have correct visualizations of Inclusions in photoreal in Carbon Viewer. Will be available also in next Cutwise version which is planning to be released on 29th of Nov, 2021.

Improvement of refinement algorithm for building of models in HP Crown Reflect scanner. This improve the accuracy for some semi-RBC models.

In I3D Mini View Report now slopes of girdle facets are displayed in the range [0, 180] degrees.

Alignment procedures transfer from HPPacor to HPCarbon

Following alignment procedures are transferred from HPPacor to HPCarbon:

Fixed problems and improvements

The following fixes for the known problems and improvements are implemented:

- There were problems with the Goodwin Cuts:

The questions regarding Goodwin Cuts are resolved ( LR-157 - Getting issue details... STATUS ):

Issue name Path Status Baguette Dropbox (OctoNus)\Request_ 2021\Smart AnyCut\HPC 1.3.53 Goodwin Cuts\Baguette Fixed \ Tested Condition A Dropbox (OctoNus)\Request_ 2021\Smart AnyCut\HPC 1.3.53 Goodwin Cuts\Princess_3Chevron Fixed \ Tested Condition B Dropbox (OctoNus)\Request_ 2021\Smart AnyCut\HPC 1.3.53 Goodwin Cuts\Princess_3Chevron Fixed \ Tested Condition C Dropbox (OctoNus)\Request_ 2021\Smart AnyCut\HPC 1.3.53 Goodwin Cuts\Princess_3Chevron Fixed \ Tested Emerald_4Step Dropbox (OctoNus)\Request_ 2021\Smart AnyCut\HPC 1.3.53 Goodwin Cuts\Emerald Fixed \ Tested Pear_wBT Dropbox (OctoNus)\Request_ 2021\Smart AnyCut\HPC 1.3.53 Goodwin Cuts\Pear Fixed \ Tested Radiant Dropbox (OctoNus)\Request_ 2021\Smart AnyCut\HPC 1.3.53 Goodwin Cuts\Radiant Fixed \ Tested The Crown form was distorted for Goodwin Cuts Radiant and Princes. (part of LR-157 - Getting issue details... STATUS ) - now this is fixed.

Grey inclusions were not ignored before in Smart Recut solutions like in Recut solutions but should be ignored - now it is fixed.

AutoCloud In Carbon Viewer was shown as Full area of probable location but not cloud of points - LR-141 - Getting issue details... STATUS - this is fixed.

Upload to cutwise button gets disabled in particular sequence of condition - LR-165 - Getting issue details... STATUS - this is fixed.

Fix of wrong orientation of Heart Shape semi-polish model in the report after scanning - LR-167 - Getting issue details... STATUS

Not working recognition in some particular examples - now they are working - LR-127 - Getting issue details... STATUS

Crown Reflect girdle profile is now correctly aligned on Girdle photo for some semi-polished RBC's - LR-84 - Getting issue details... STATUS

Resolved requests - list

Below is the list of Lexus requests resolved within this release. On this page above, you can find a detailed description of what was changed - search by Key.